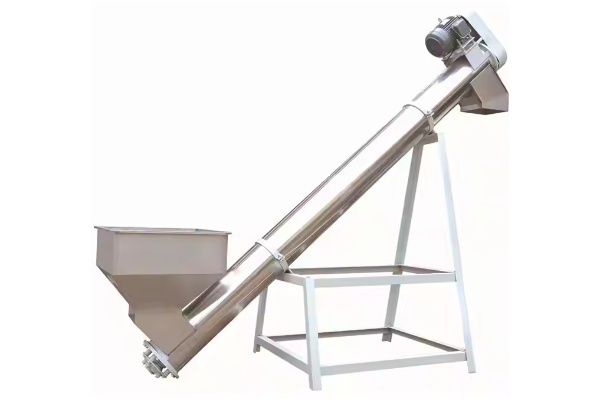

Stainless Steel Inclined Screw Conveyor

The price of Stainless Steel Inclined Screw Conveyor varies greatly depending on factors such as its material grade, inclination angle. Its price ranges from US$100 to US$6,000.

Rotation speed: 45-70 R/Min

Size (L*W*H): 2000*200 * 220mm/customizable

Frame material: carbon steel/stainless steel

Power: 0.4kW-22kW

Voltage: 220V/380V/415V

Frequency: 50/60Hz

What is Stainless Steel Inclined Screw Conveyor?

The main function of Stainless Steel Inclined Screw Conveyor is to lift powdery, granular or small block materials from a lower position to a higher position. This type of equipment can be roughly divided into small inclination (0° to 20°), medium inclination (20° to 45°) and large inclination (45° to 90°) types according to its inclination angle to adapt to different material lifting needs and site restrictions. In terms of material handling capacity, Stainless Steel Inclined Screw Conveyor can handle materials from several cubic meters to tens of cubic meters per hour, and the conveying distance of a single device usually ranges from several meters to more than 20 meters.

What are the types of Stainless Steel Inclined Screw Conveyor?

Stainless Steel Inclined Screw Conveyor is a conveying equipment widely used in food, chemical and other industries. Its core feature is that the conveying path is inclined, and stainless steel is used to meet hygiene or corrosion protection requirements. According to the inclination angle, it can be roughly divided into the following types:

Small inclination angle screw conveyorInclination angle range: usually refers to the inclination angle between 0° and 20°.

Design features: In this angle range, the material can maintain good fluidity and filling rate under the push of the spiral blade, similar to horizontal conveying, but with a certain lifting capacity. Usually no special anti-backflow structure is required, or only simple adjustment is required.

Applicable materials: Suitable for most powdery and granular materials with good fluidity, such as grains, flour, small granular plastics, dry powders, etc.

Inclination angle range: usually refers to the inclination angle between 20° and 45°.

Design features: In this angle range, the tendency of material to reflux under the action of gravity begins to become obvious. In order to ensure effective conveying, measures may need to be taken, such as increasing the spiral speed, increasing the filling rate of the spiral blade, or using a variable pitch design to compensate for the influence of gravity. For some materials that are prone to slipping, special spiral blade forms may be required.

Applicable materials: It is still applicable to most powdery and granular materials, but the viscosity and fluidity requirements of the materials are slightly higher.

Inclination angle range: usually refers to the inclination angle between 45° and 90° (vertical).

Design features: In this angle range, the influence of gravity on the material is very large, and the efficiency of traditional screw conveying will be greatly reduced. Therefore, this type of conveyor usually requires special design, such as a fast-rotating closed screw. Driven by the high-speed rotating screw, the material is thrown to the pipe wall by centrifugal force and pushed up by the spiral blades, similar to the working principle of a centrifugal pump. Special spiral blades may use non-standard pitch, widened blades or special shapes to better grasp and lift materials. Higher drive power, overcoming gravity to do work, requires greater motor power.

Applicable materials: It is suitable for powdery or small granular materials with good fluidity and not easy to agglomerate, and has certain requirements for the friction coefficient and viscosity of the material.

What are the advantages of Stainless Steel Inclined Screw Conveyor?

Stainless Steel Inclined Screw Conveyor offer significant advantages in material handling applications requiring high standards of hygiene, corrosion resistance, material lifting capacity, excellent sealing, stable and continuous conveying, wide adaptability, and easy maintenance.

Excellent hygiene and corrosion resistance: This is the core advantage of Stainless Steel Inclined Screw Conveyor. All parts in contact with the material are made of food-grade stainless steel (such as 304 or 316L). This material has excellent corrosion resistance and can resist the erosion of various corrosive media such as acids, alkalis, and salts, ensuring the stable operation of the equipment in a humid and highly corrosive environment. At the same time, the surface of stainless steel is smooth, not easy to absorb materials, easy to clean and disinfect, and can effectively prevent material contamination and bacterial growth.

Realize material height difference transportation: The inclined design enables it to lift materials from a lower position to a higher position, effectively utilizing space. Whether feeding from a ground hopper to a high-level mixing tank or lifting materials to a packaging machine or storage bin, the Stainless Steel Inclined Screw Conveyor can complete the vertical height transfer within a limited footprint, simplify the process flow, and reduce the need for additional lifting equipment.

Strong airtightness: Compared with ordinary conveying equipment, the Stainless Steel Inclined Screw Conveyor usually adopts a fully enclosed tubular or covered trough structure. This design effectively prevents material leakage and dust flying during transportation, and improves the cleanliness of the working environment. At the same time, it also protects the material from contamination by the external environment, which is especially important for powder or granular materials with high requirements for purity.

Stable operation and continuous conveying: The screw conveyor can provide a continuous and smooth material flow to ensure a smooth production process. Despite the inclined conveying, through reasonable pitch, speed and blade design, the equipment can effectively overcome the influence of gravity, prevent material backflow or slippage, and ensure stable lifting and conveying of materials.

Wide adaptability and convenient maintenance: Stainless Steel Inclined Screw Conveyor is suitable for conveying a variety of powdered, granular, and small block materials. The spiral blade form (such as variable pitch, paddle blade) and speed can be adjusted according to different material characteristics. In addition, many stainless steel screw conveyors are also designed with quick-open or easy-to-disassemble structures to facilitate internal inspection, cleaning, and maintenance, thereby extending the service life of the equipment and reducing operating costs.

Parameters of Stainless Steel Inclined Screw Conveyor

| odel |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the structural features of a Stainless Steel Inclined Screw Conveyor?

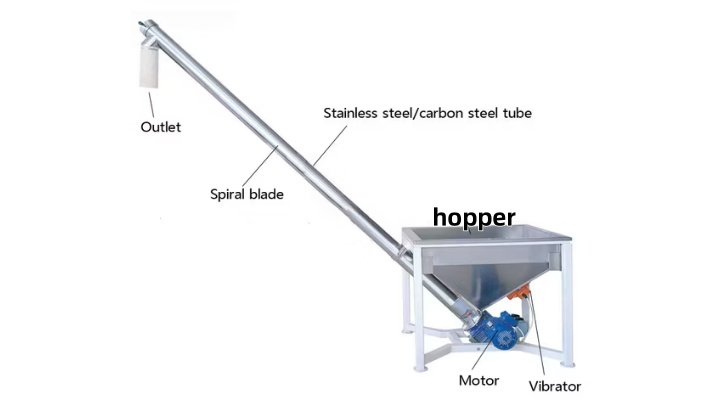

Stainless Steel Inclined Screw Conveyor is a device used to lift and convey materials. Its structural design allows it to adapt to inclination angles while maintaining the excellent properties of stainless steel. Its main components are as follows:

Spiral blades

The spiral blades are the core component of the stainless steel Inclined screw conveyor, responsible for propelling and lifting materials.

Material: Typically made of food-grade stainless steel, such as 304 or 316L. These materials offer excellent corrosion resistance, are easy to clean, and meet hygienic standards.

Spiral blades come in a variety of forms, with the most common being a solid spiral suitable for conveying most powdered and granular materials. Belt screws are suitable for materials with low viscosity or poor flowability, reducing adhesion during conveying. Paddle screws offer stirring or mixing functions and are suitable for materials requiring a certain mixing effect. Variable-pitch screws can control the filling level or achieve compression.

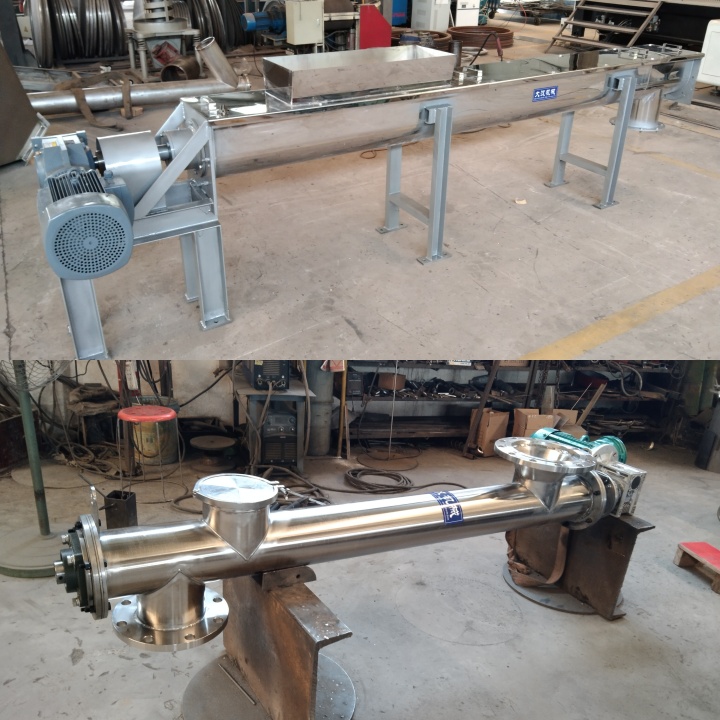

Conveyor Trough/Pipe

The conveyor trough or pipe is the external structure that carries the material and surrounds the screw blades.

Trough: Commonly used for horizontal or low-angle conveying, it often features a cover for easy cleaning and maintenance.

Tube: Suitable for high-angle conveying and fully enclosed conveying, it effectively prevents material leakage and external contamination, improving sealing. Tube structures also make it easier to lift materials to a higher height.

Support: The conveyor trough or pipe requires a sturdy support and base to support the entire conveyor and withstand the impact and vibration of the material. The angle of inclination can be adjusted or fixed using a bracket.

Drive: The drive provides the power for the screw conveyor.

Motor: This provides rotational power and is typically a three-phase asynchronous motor. The appropriate power is selected based on the conveying volume and material characteristics. Reducer: Converts the high-speed rotation of the motor to the lower speed required by the screw shaft while providing sufficient torque. Common reducer types include cycloidal pinwheel reducers and worm gear reducers.

Coupling: Connects the motor and reducer, or the reducer and screw shaft, transmitting torque and compensating for minor shaft misalignment.

Inlet and outlet: The inlet and outlet are the interfaces through which material enters and exits the conveyor.

The inlet: Typically located at the lower end of the conveyor, material enters the screw conveyor. The design considers the free flow of the material and the connection method with upstream equipment.

The outlet: Located at the upper end of the conveyor, material is discharged from this outlet. The outlet design is customized based on the connection method of downstream equipment (e.g., direct discharge, pipe connection, etc.).

Seals: The inlet and outlet are typically equipped with appropriate seals to prevent dust escape or material leakage.

What are the applications of Stainless Steel Inclined Screw Conveyor?

Stainless Steel Inclined Screw Conveyor is widely used in various industrial and production scenarios. Its core function is to safely, hygienically and continuously lift various types of powdered, granular or small block materials from low to high.

Material height difference transfer: It can effectively transport materials from a lower collection point, hopper or ground to a higher mixing equipment, reactor, dryer, packaging machine feed or storage silo. This lifting capacity allows the material handling process to be arranged vertically, saving horizontal space.

Process flow connection: In multi-stage production lines, Stainless Steel Inclined Screw Conveyor is often used to connect processing units at different heights. For example, after the material is initially processed (such as mixing and screening), it needs to be lifted to the next processing link (such as filling, tableting, drying). It can provide a continuous and controlled material flow to ensure the smooth connection of the production process.

Material conveying in controlled environments: Due to the use of stainless steel and the usually closed design, this type of conveyor is suitable for occasions with strict requirements on environmental cleanliness, material purity or corrosion protection. It can prevent the material from being contaminated by the outside during the conveying process, or prevent the material itself from corroding the conveying equipment, ensuring the hygiene of the production environment and the long-term operation of the equipment.

Metering and precise feeding assistance: Stainless Steel Inclined Screw Conveyor can be used in conjunction with weighing equipment or metering systems to achieve accurate and quantitative lifting and feeding of materials. This is particularly important in processes that require feeding high-level containers according to specific recipes, ensuring the accuracy and consistency of production.

Occasions with high requirements for cleaning and maintenance convenience: Considering the easy cleaning and disinfection characteristics of stainless steel, this type of conveyor is particularly suitable for production lines that require frequent material changes and thorough cleaning to prevent cross contamination. Its design usually takes into account quick disassembly and convenient maintenance for regular cleaning.

Manufacturers of Stainless Steel Inclined Screw Conveyor

Stainless Steel Inclined Screw Conveyor manufacturers ensure that their equipment is precisely matched to the user's specific production needs when providing equipment. When choosing a Stainless Steel Inclined Screw Conveyor, users need to consider many factors. The first is the material characteristics, including its bulk density, particle size, viscosity, abrasiveness, whether it is susceptible to moisture or corrosion, and specific requirements for hygiene. For example, the spiral blade design required for conveying fine powders and coarse particles will be different, and highly viscous materials may be more suitable for a shaftless spiral structure. The second is the conveying parameters, such as the amount of material to be conveyed per hour (handling capacity), the specific lifting height and the horizontal conveying distance. These parameters directly determine the diameter of the spiral, the speed and the required motor power. In addition, the installation environment is also crucial, including the available space size, whether there are other equipment obstructions, and the requirements for noise, vibration and explosion-proof levels. Manufacturers can provide detailed selection guidance based on user needs. Based on the specific data provided by the user, combined with their own experience and technical specifications, the manufacturer will recommend the appropriate screw diameter, pitch, speed range, and determine the required drive power. In addition, the manufacturer will recommend the corresponding stainless steel grade (such as 304 or 316L) according to the corrosiveness of the material, and recommend the surface treatment process (such as mirror polishing) according to the hygiene level requirements. The manufacturer has strong customization capabilities and can provide flexible solutions based on the customer's specific production process and site conditions. For example, for the adhesion or fluidity of special materials, the manufacturer can adjust the shape and pitch of the spiral blades, and even design a variable pitch spiral to ensure smooth lifting of the material. For materials that are difficult to clean, quick-release, retractable spirals or segmented casing designs can be provided for thorough cleaning. According to the complex production line layout, the manufacturer can design multi-point feed ports or multi-point discharge ports to achieve flexible distribution and collection of materials and reduce additional conveying links. Through these customized services, Stainless Steel Inclined Screw Conveyor manufacturers can provide solutions that are highly matched with customers' specific production processes and material characteristics.

Stainless Steel Inclined Screw Conveyor Case

Stainless Steel Inclined Screw Conveyors, with their unique structural and material advantages, are widely used across multiple industries, particularly in applications with stringent requirements for hygiene, corrosion resistance, and material lifting. Food processing equipment demands extremely high hygienic standards, and stainless steel (such as 304 or 316L) effectively prevents material contamination and bacterial growth. In the food industry, stainless steel inlined screw conveyors are used to lift powdered or granular materials such as flour, starch, sugar, grain, and coffee beans from floor hoppers to mixers, mixing tanks, or packaging lines. They are also used to transport biscuit crumbs, meat products, fruit and vegetable granules, and seasonings, often for high-level transfers between different production process steps. In frozen food and baked goods production lines, they are used to vertically lift materials and utilize space during cooling or proofing, while maintaining stable operation in low-temperature environments. In the chemical industry, particularly in fine chemicals and applications handling corrosive materials, stainless steel inlined screw conveyors demonstrate their corrosion resistance. It is used to transport corrosive powder or small granular chemical raw materials such as acids, alkalis, and salts. For some chemical products with high purity requirements, stainless steel can effectively prevent the mixing of impurities. It effectively controls dust during the transportation process and improves the working environment. In addition to the main fields mentioned above, Stainless Steel Inclined Screw Conveyor also plays a role in many other industries, such as the feed industry, transporting various feed raw materials and finished feeds such as corn meal, soybean meal, fish meal, etc. In grain processing, it is used to lift and transport grains, flour, etc. In building materials, it is used for fine granular materials that need to be lifted and corrosion-resistant, such as certain additives and special cement. In general, Stainless Steel Inclined Screw Conveyor plays an indispensable role in industrial production that requires high standards, high cleanliness and vertical transportation due to its excellent hygiene, corrosion resistance, sealing and material lifting capacity.

Stainless Steel Inclined Screw Conveyor plays a role in the current material handling process. Its advantage lies in its ability to provide a hygienic material conveying environment, thanks to its stainless steel material, which helps prevent material contamination and resists corrosion. At the same time, the equipment can achieve material height difference transfer and complete material lifting in a limited space. Its closed structure helps control dust, and the equipment itself is easy to clean and maintain. These characteristics make it a practical tool for application scenarios where powdered or granular materials need to be transferred from low to high places, and there are specific requirements for hygiene and equipment durability.