stainless screw conveyor price

Tuesday December-09 2025 10:58:45

stainless screw conveyor price varies considerably, typically between $100 and $5,000, influenced by a variety of factors. These factors include the specific type of equipment, the grade of stainless steel used, the physical dimensions of the equipment, the required throughput, and the configuration of accessories. In current industrial applications, the practical requirements for equipment cleanliness and corrosion resistance are key factors determining the cost of stainless steel screw conveyors.

What are the types of stainless screw conveyor price?

Stainless steel screw conveyors can be divided into several types according to their structure, working principle and application scenarios. The differences between these types directly lead to significant differences in stainless screw conveyor price. The following is a price comparison of four common types.

U-shaped stainless steel screw conveyors: Their manufacturing process and sealing requirements are generally lower than those of fully enclosed pipelines, and their price is also relatively lower. Manufacturing costs mainly lie in the cutting, bending, and welding of stainless steel plates, as well as the processing of the helical blades.

Tube-type stainless steel screw conveyors: Compared to U-shaped screw conveyors, tube-type stainless steel screw conveyors are generally more expensive. Their manufacturing costs include the rolling of round tubing, more precise welding processes, and the requirements for pipe flanges and inlet/outlet seals.

Shaft-mounted stainless steel screw conveyors: This is a traditional screw conveyor design and a relatively common and economical type of stainless steel screw conveyor. Its price is mainly affected by the material, diameter, and manufacturing process of the central shaft.

Shaftless stainless steel screw conveyors: Shaftless stainless steel screw conveyors are generally more expensive than shafted conveyors with equivalent conveying capacity. Their manufacturing costs are reflected in the special processing of the shaftless helix, the installation of the trough lining, and the special bearing support structure.

stainless screw conveyor price parameter table

| Type | Model Example | Pipe Diameter/Trough Width (mm) | Length (m) | Power (kW) | Capacity (t/h) | Reference Price Range (USD) |

| U-type Stainless Steel Screw Conveyor | SS-U200 | 200 | 3-8 | 1.5-3.0 | 2-8 | $2,500 - $7,000 |

| Tubular Stainless Steel Screw Conveyor (Round Pipe Type) | SS-T250 | 250 | 5-12 | 2.2-5.5 | 5-15 | $5,000 - $13,000 |

| Shafted Stainless Steel Screw Conveyor | SS-S300 | 300 | 6-15 | 3.0-7.5 | 10-30 | $7,000 - $17,000 |

| Shaftless Stainless Steel Screw Conveyor | SS-SL350 | 350 | 4-10 | 4.0-11 | 15-40 | $9,000 - $20,000 |

What are the factors affecting stainless screw conveyor price?

In addition to the above price differences by type, the following factors will also have a significant impact on the final quotation of the stainless screw conveyor.

Stainless Steel Grades and Surface Treatments: 304 stainless steel offers excellent corrosion resistance and processing performance. 316L stainless steel is more suitable for strong acid and alkali environments or applications requiring even higher corrosion resistance, but its cost is significantly higher than 304 stainless steel. Sometimes, stainless steel surfaces require treatment. Brushing is relatively inexpensive, while mirror polishing requires fine grinding and polishing processes, which greatly increases processing costs.

Conveying Capacity and Dimensions: The larger the spiral diameter, the more metal sheet is required, increasing processing difficulty and transportation costs. Longer equipment lengths not only increase material costs but also transportation and installation costs. Conveying capacity, conveying distance, conveying angle, and material characteristics collectively determine the required motor power. Higher power results in higher costs for the motor and reducer.

stainless screw conveyor price component

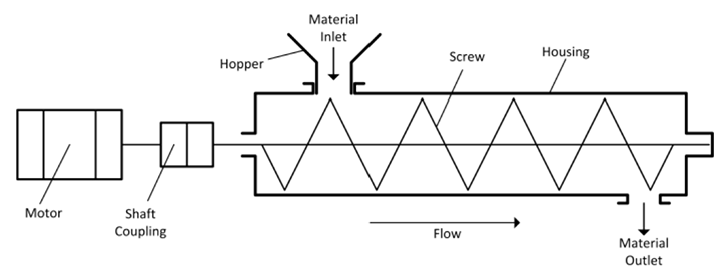

stainless screw conveyor price is closely related to the components that make up the equipment.A screw conveyor primarily consists of a drive unit (motor, reducer), a drive shaft, spiral blades, a U-shaped trough, a feed port, a discharge port, an intermediate bearing, and end brackets. Its operating principle is as follows: when the motor drives the screw shaft to rotate, the spiral blades embedded in the trough rotate synchronously, causing the material fed into the feed port to move axially along the fixed U-shaped trough under the continuous propulsion of the blades. This process is like a rotating nut moving axially along the screw, ultimately forcing the material to be conveyed to the discharge port for discharge, thus achieving continuous conveying operations in confined spaces, whether horizontally, inclined, or over short distances vertically.

Stainless Screw Conveyor Manufacturers

There are many stainless screw conveyor manufacturers, some specialize in the manufacture of shaftless screw conveyors, and some specialize in the manufacture of shafted screw conveyors. Machrise is suitable for 304/316 stainless steel materials and supports customized stainless steel shafted/shaftless screw conveyors with a conveying capacity of up to 458 cubic meters/hour,the stainless screw conveyor is competitively priced. It is a professional source supplier.

In actual application, the purchase cost of the stainless screw conveyor reflects the investment in materials, processes and components involved in the manufacture of the equipment. To select a device suitable for specific production needs, it is necessary to comprehensively evaluate its structural characteristics, achievable conveying parameters and compatibility with existing production lines. The long-term operation and maintenance of the equipment, including the replacement of parts and daily cleaning, are also aspects that need to be considered during use.