Stainless Steel Vacuum Loading Machine

The core advantage of the Stainless Steel Vacuum Loading Machine lies in its all-stainless steel construction. For example, the alloy ratio of stainless steel, with a chromium content of ≥18% and a nickel content of ≥8%, gives the material excellent resistance to acid and alkali corrosion.

Belt Material: Stainless Steel

Voltage: 380V / Customizable

Application: Product Conveying

Frame Material: 304, 316 Stainless Steel

Conveying Capacity: 10 kg - 10 tons/hour

Length: Customizable, 1-100 meters

Conveyed Materials: Granular and powdered products

Applicable Industries: Providing high-standard stainless steel vacuum loading solutions for the food, pharmaceutical, and chemical industries.

What is a Stainless Steel Vacuum Loading Machine?

Stainless Steel Vacuum Loading Machine is an automated conveying device made of stainless steel. It is particularly suitable for the demanding conditions of aseptic production or handling corrosive materials. Whether it's milk powder, APIs, or chemical granules, a stainless steel vacuum loading machine can ensure material purity while increasing conveying efficiency by over 50%. Furthermore, it is portable and can be moved around in different scenarios. Our stainless steel vacuum loading machines can also be customized to meet your production needs, allowing for optimal integration with other production equipment.

What materials are used for stainless steel vacuum loading machines?

The core competitiveness of stainless steel vacuum loading machines lies in their material properties. Depending on the industry requirements, three main types of stainless steel are used.

304 stainless steel: Containing 18% chromium and 8% nickel, it offers basic corrosion and oxidation resistance, a smooth and easy-to-clean surface, and is suitable for food processing (such as grain and candy granules) and general chemical applications. It offers a reasonable cost and a high performance-to-price ratio.

316L stainless steel: Adding molybdenum to 304 stainless steel improves corrosion resistance by over 30%. It is particularly resistant to acidic and alkaline solutions and high temperatures. It is the standard for conveying additives in the pharmaceutical industry (e.g., pharmaceutical granules and capsules) and seawater desalination, meeting stringent GMP requirements.

Duplex stainless steel: Combining the advantages of austenitic and ferritic stainless steel, it offers increased strength and resistance to intergranular corrosion. It is suitable for conveying high-concentration chemical raw materials (e.g., catalyst particles) and special materials containing chloride ions, with a service life 2-3 times that of ordinary stainless steel.

Advantages of the Stainless Steel Vacuum Loading Machine

The stainless steel vacuum loader is constructed of stainless steel and designed specifically for high-hygiene industries such as food, pharmaceutical, and chemical industries. It offers the following irreplaceable advantages:

High corrosion resistance: Resists corrosive media such as acids, alkalis, and salts, extending equipment life.

Compliant with hygiene standards: Mirror-polished surface, seamless design, and certified hygiene.

Easy to clean and disinfect: Supports CIP/SIP cleaning to meet aseptic production requirements. High strength and durability: Wear-resistant and heat-resistant (-20°C to 400°C), suitable for harsh environments.

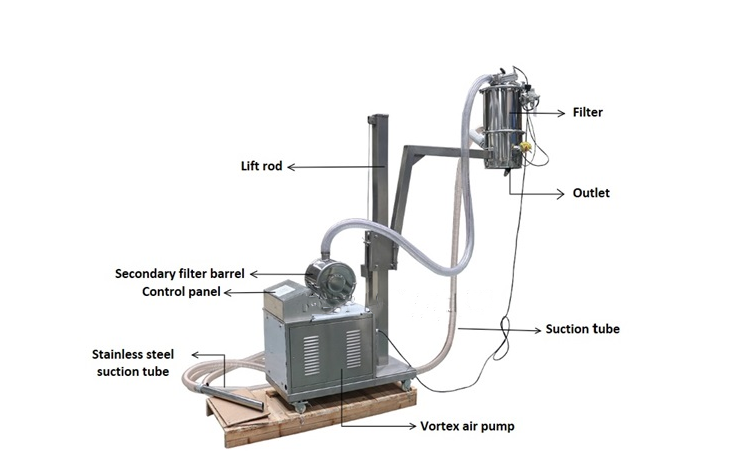

What are the main components of the stainless steel vacuum loading machine?

The modular design of the stainless steel vacuum loading machine fully unleashes the material's potential. Its quick-release clamp connection is made of 304 stainless steel, and its O-ring seal allows for rapid pipe assembly and disassembly, reducing cleaning time by 80% compared to flange connections.

Vacuum hopper: Stamped from 3mm thick 316L stainless steel and welded with argon arc welding, this ensures no deformation even at -0.095 MPa vacuum levels and can stably convey metal powders with a density of up to 2.5g/cm³.

Filter assembly: The polyester-coated filter element is housed in a 304 stainless steel frame, ensuring 1μm filtration accuracy and enabling online cleaning via a backflush system.

Conveying pipe: Internal polishing results in an inner wall roughness of less than 0.4μm. The 45° tilt design effectively prevents wet material from adhering, ensuring a stable conveying efficiency exceeding 98%.

Stainless Steel Vacuum Loading Machine Technical Specifications

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

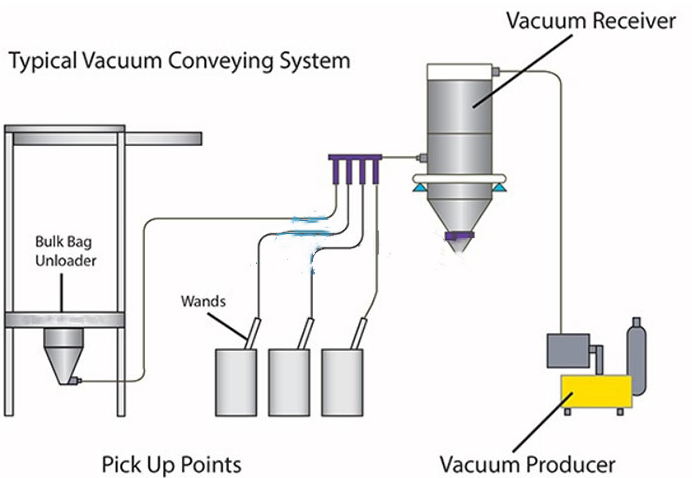

How does the Stainless Steel Vacuum Loading Machine work?

The Stainless Steel Vacuum Loading Machine operates as follows: The vacuum pump is activated to create negative pressure in the hopper. Material from the storage tank is then drawn into the hopper through a stainless steel pipe under atmospheric pressure. When the material level meter detects that the material has reached the set height, the vacuum valve automatically closes and suction stops. Compressed air then enters the backflush system to clean the filter, ensuring continuous and stable operation of the equipment. Finally, the discharge valve opens, allowing the material to fall by gravity into downstream equipment.

What industries are the Stainless Steel Vacuum Loading Machines suitable for?

Due to its corrosion resistance, sterility, and easy cleaning properties, the Stainless Steel Vacuum Loading Machine is the preferred equipment for demanding industries such as the food, pharmaceutical, and chemical industries. It is widely used for the enclosed conveying of powders and granules such as milk powder, APIs, and lithium battery materials.

Food and Beverage Industry: Applied to conveying powdered or granular materials such as milk powder, powdered sugar, starch, seasonings, and coffee powder. Key requirements include compliance with food safety standards. Equipment surfaces require a mirror polish to prevent material residue and bacterial growth. Cross-contamination is also prevented through design to ensure hygienic production throughout the entire process.

Pharmaceutical and Bioengineering Industry: Primarily used for the aseptic transfer of APIs, excipients, granules, and capsule fillers, it must meet aseptic production specifications and utilize 316L stainless steel, supporting CIP/SIP cleaning and sterilization.

Chemical and New Materials Industry: Applicable to conveying corrosive chemical particles (such as dyes, fertilizers, and resins) and lithium battery materials (positive and negative electrode powders). Equipment must possess acid, alkali, and oxidation resistance to withstand highly corrosive environments.

Cosmetics and Daily Chemicals Industry: Applicable to conveying materials such as foundation, talcum powder, laundry detergent, and fragrance granules. Key requirements include non-toxic and harmless materials and protection against metal contamination.

Why is stainless steel a must for these industries?

These industries must choose stainless steel vacuum loading machines. The core reason is that the properties of stainless steel are highly compatible with the industry's stringent requirements, specifically in terms of compliance, safety, and durability.

Compliance: Industries like the food and pharmaceutical industries are subject to mandatory regulations such as FDA and GMP. Stainless steel is the only material certified for food contact safety and meets aseptic production specifications, directly mitigating compliance risks associated with carbon steel and other materials due to corrosion and release of hazardous substances.

Safety: The mirror-polished, non-porous surface of stainless steel eliminates material residue and bacterial growth, preventing quality issues in food and pharmaceuticals caused by equipment contamination. Furthermore, its chemical stability is extremely strong, and it does not react with chemical raw materials or cosmetic ingredients, preventing material denaturation or contamination by metallic impurities.

Durability: Stainless steel's acid, alkali, corrosion, and high-temperature resistance make it suitable for the humid environments of food processing, the cleaning and sterilization processes of the pharmaceutical industry, and the highly corrosive materials of the chemical industry. Its service life is 3-5 times that of carbon steel, significantly reducing the cost of frequent equipment replacement.

Stainless Steel Vacuum Loading Machine Customer Solutions

The Stainless Steel Vacuum Loading Machine provides high-standard stainless steel vacuum loading solutions for the food, pharmaceutical, and chemical industries. Selected customer cases demonstrate how to achieve aseptic conveying, corrosive material handling, and compliant production.

Dairy companies: Faced with hygienic risks in milk powder conveying, the solution utilizes a 316L stainless steel vacuum loader. Its mirror-polished interior creates a zero-dead-angle design, integrates a CIP cleaning system and PTFE sterile filter, and achieves fully enclosed operation with a conveying capacity of 2 tons/hour.

Pharmaceutical companies: Safely transfer highly active APIs without operator exposure. The customized 316L stainless steel isolator vacuum loader features a fully enclosed design, equipped with a SIP sterilization port, a HEPA filter, and anti-static features to prevent material adsorption.

Chemical companies:need to transport highly corrosive dye particles containing acidic components in explosion-proof areas. The solution is a 304 stainless steel PTFE-lined machine. It can withstand strong acid and alkaline environments with a pH range of 1-14. It features an ATEX-compliant motor and control cabinet, along with a nitrogen protection system to eliminate explosion risks.

How much does a stainless steel vacuum loading machine cost?

Prices for stainless steel vacuum loaders start as low as $500, with various factors influencing the specific price. Basic models, made of ordinary 304 stainless steel and featuring a simpler structure, are suitable for small-scale material handling applications with less demanding functionality. Prices range from $500 to $1500. Using more corrosion-resistant 316L stainless steel, or for larger load capacities and equipped with a more automated control system, prices can rise to $1500 to $3000. For specialized industry requirements, such as high-purity customization for the food and pharmaceutical industry or explosion-proof design for the chemical industry, the cost will increase further. If you require a stainless steel vacuum loading machine, please feel free to contact us for a detailed price list.

Why choose us as your stainless steel vacuum loading machine supplier?

Our stainless steel vacuum loading machines feature patented mirror polishing and seamless welding technology, eliminating sanitary blind spots. Made of 304/316L stainless steel with qualified nickel and chromium content, they can be customized to meet your needs, covering various industry requirements and offering flexible functions with a capacity range of 0.1-20t/h. We offer transparent pricing, with tiered quotes starting at $500 and clear material premiums. We can recommend the most suitable loading equipment based on your production site and capacity. We also offer process production lines, allowing the equipment to be integrated with screening machines, packaging machines, conveyors, and mixers.

From closed-loop conveying to intelligent monitoring, and from standard modules to customized solutions, the Stainless Steel Vacuum Loading Machine, grounded in material innovation, continues to drive transformation in the industrial material handling sector. It not only meets the core demands of modern manufacturing for clean production and rapid operation and maintenance, but also, through the deep integration of materials and technology, provides critical support for building an intelligent and sustainable industrial ecosystem.