Animal Feed Vacuum Loading Machine

Animal Feed Vacuum Loading Machine, with its closed-loop conveying, dust-free operation, and high degree of automation, can be integrated with a variety of equipment to achieve seamless integration throughout the entire feed production process.

Power: 1.5-5.5 kW (customizable)

Dimensions (L*W*H): Depends on the specific model

Material: 304/316 stainless steel

Voltage: 220V/380V/415V or customizable upon request

Customization: Acceptable

Type: Pneumatic/Electric/Continuous

Core Components: Motor, bearings, gears, pump, gearbox, engine

Applicable Materials: Corn, soybean meal, hay, fish meal, lime powder, vitamins, probiotics, enzymes

What is an Animal Feed Vacuum Loading Machine?

Animal Feed Vacuum Loading Machine is an automated conveying device designed specifically for feed production. Its core goal is to address the challenges of dust contamination, cross-contamination, and moisture absorption and clumping during the transfer of materials such as corn, soybean meal, and vitamin premixes. Powered by an oil-free vacuum pump, it creates a stable negative pressure within a closed system consisting of a suction nozzle, conveying piping, separation hopper, and filter assembly. This pressure differential drives material transport.

The material-contacting parts of the Animal Feed Vacuum Loading Machine are constructed of 304 food-grade stainless steel. The polished interior prevents residue and is easy to clean. It also features a moisture-proof seal and is suitable for various feed forms, including powders and granules. The fully enclosed process eliminates dust leakage, ensuring feed quality and production hygiene. It can also be integrated with screening machines, mixers, and packaging machines, promoting automation upgrades in feed production facilities.

What are the advantages of the Animal Feed Vacuum Loading Machine?

The feed vacuum loader significantly saves labor and time costs with its high-speed automated conveying capabilities. The fully enclosed pipeline eliminates dust leakage, ensuring a clean and environmentally friendly production environment and significantly reducing material loss and cross-contamination.

Improved Efficiency: Conveying efficiency is 2-4 times higher than traditional manual feeding. One unit can replace 2-3 workers, making it particularly suitable for large-scale feed mills with 24-hour continuous production.

Reduced Loss: The fully enclosed conveying mode reduces feed material loss from 3%-5% with manual feeding to below 0.2%, while also eliminating raw material waste caused by dust and reducing production costs.

Ensuring Quality: The anti-residue and anti-cross-contamination design eliminates the risk of mixing feeds from different batches and varieties. The moisture-proof sealing structure prevents moisture absorption and deterioration of raw materials, ensuring stable feed nutritional content.

Customizable Animal Feed Vacuum Loading Machine Functions

In response to the diverse feed production processes of our customers, we offer Animal Feed Vacuum Loading Machines with flexible customization to meet diverse production needs.

Precise Delivery of Trace Additives: To meet the needs of dosing trace additives such as vitamins and minerals in premix feed production, we can customize a "low-flow precision delivery system" equipped with a high-precision level sensor and variable-frequency vacuum pump.

Multi-station and Long-Distance Delivery: For large feed mills that feed multiple pellet mills and mixers simultaneously, we can design a "one-to-many" delivery system, utilizing pipeline switching valves to achieve precise feeding to different equipment.

Cleaning and Interconnection Adaptation: For production lines that frequently change feed types, the machine supports "Quick Disassembly and Cleaning." The hopper and pipelines are connected by clamps, allowing for tool-free disassembly and assembly, reducing cleaning time to less than 30 minutes.

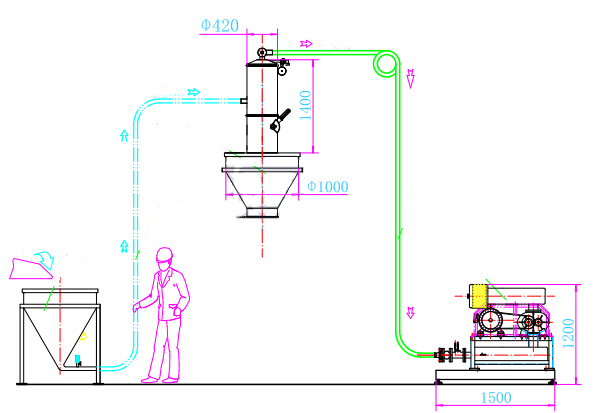

Operating Principle of the Animal Feed Vacuum Loading Machine

Powered by an oil-free vacuum pump, the Animal Feed Vacuum Loading Machine extracts air from the closed conveying system consisting of the suction nozzle, conveying pipeline, separation hopper, and filter assembly, creating a stable negative pressure. After the machine is started, negative pressure at the suction nozzle leverages atmospheric pressure to push feed material into the pipeline, where it moves smoothly with the airflow to prevent clogging. Once the material reaches the separation hopper, it passes through a metal mesh filter to separate the air and material. Gravity settles to the bottom of the hopper, where the filter protects the vacuum pump. When the material level sensor detects that the preset level has been reached, the vacuum pump shuts down, the pneumatic discharge valve opens, and the material falls into the target equipment. After discharge, the valve closes and the pump restarts, entering the next cycle.

Animal Feed Vacuum Loading Machine Technical Specifications

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

Where can the Animal Feed Vacuum Loading Machine be used?

As a core conveying device, the Animal Feed Vacuum Loading Machine is used throughout the entire modern feed production process. It is primarily used for dust-free raw material reception and feeding, enabling high-speed, automated transfer between process steps.

Raw Material Receiving and Pre-processing: In feed mill warehouses, vacuum loaders can directly draw bulk corn and soybean meal from trucks or containers into vertical silos, replacing manual unloading and forklift transfers.

Batching and Mixing: In multi-component batching systems, the vacuum loader can simultaneously connect to multiple raw material silos and trace additive dosing stations, achieving precise batching through time-proportioned control.

Pelletizing and Extrusion: Before the pelletizer, the vacuum loader stably delivers conditioned powder to the gap between the rollers, preventing uneven pellets or machine blockages caused by insufficient feed.

Packaging and Finished Product Storage: In the packaging process, the vacuum loader transports finished feed from the finished product silo to the hopper of the automatic packaging machine, supporting packaging specifications ranging from 25 kg/bag to 1 ton/bag.

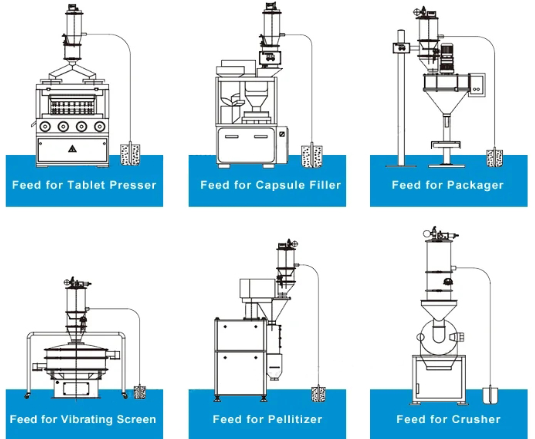

Which equipment can the Animal Feed Vacuum Loading Machine be used with?

The Animal Feed Vacuum Loading Machine, with its closed-loop conveying, dust-free, environmentally friendly, and highly automated features, can be integrated with various equipment to achieve efficient integration throughout the entire feed production process.

Vacuum Loader + Screener: The vacuum loader uses negative pressure to convey feed ingredients such as corn and soybean meal from the storage silo to a vibrating or ultrasonic screen. The screener uses high-frequency vibration or ultrasound to separate impurities and unqualified pellets.

Vacuum Loader + Packer: The vacuum loader conveys finished feed to the hopper of a pellet or ton bag packaging machine. The packaging machine uses a weighing sensor and a screw feeder to quantitatively fill the feed, achieving an accuracy of ±0.1% for a 25kg bag and within 0.5% for a 1-ton bag.

Vacuum Loader + Mixer: The vacuum loader conveys corn, soybean meal, vitamin premix, and other ingredients according to the recipe to a ribbon or double-screw conical mixer. The mixer's spiral blades circulate the materials, allowing a 10-ton batch of feed to be mixed in just 8 minutes.

Vacuum loader + conveyor: Combining a vacuum loader with a screw or pneumatic conveyor can transport materials over 50 meters horizontally and 30 meters vertically, at rates exceeding 10 tons per hour. This combination reduces transfer steps and consumes 50% less energy than mechanical conveying.

How to Choose the Right Animal Feed Vacuum Loading Machine?

When selecting a material, consider the material properties, conveying requirements, and production environment. The key is to ensure the equipment is perfectly matched to your specific process, enabling high-speed, dust-free, automated conveying.

Material Property Matching: For powdered materials, select equipment with high filtration accuracy, corrosion resistance, and easy cleaning to prevent contamination. For granular materials, prioritize wear-resistant pipes and vacuum pumps to extend service life. For mixed materials, evaluate the particle distribution and select equipment with a clogging-resistant design. For special materials, low-pressure, economical equipment can be selected for lightweight materials, while high-pressure, high-power models are required for heavy materials.

Conveying Parameter Compatibility: For short distances (<10 meters), standard models are suitable. For medium and long distances (10-50 meters), high-pressure, high-volume vacuum pumps are required. For extremely long distances (>50 meters), customized high-power equipment or an intermediate buffer silo are required.

Operating Environment Adaptability: For high-temperature environments, select high-temperature-resistant materials and a cooling system to prevent equipment deformation. For high-humidity environments, reinforced sealing design or a drying device are required to prevent moisture absorption and clumping of the material. In terms of industry-specific requirements, equipment in the food and pharmaceutical industries must meet hygiene standards, use 304/316L stainless steel, and have filter elements that are easily disassembled and cleaned; the chemical industry requires explosion-proof design to ensure safety.

Animal Feed Vacuum Loading Machine Manufacturer

We have dedicated many years of experience in the research and development and manufacture of animal feed vacuum loading machines. Our strong technical team can accurately understand the specific characteristics of the feed industry. From conveying pellets like corn and soybean meal to powders like vitamin premixes, we can customize solutions based on the material's characteristics. Our equipment is constructed of 304 food-grade stainless steel to meet feed hygiene standards. We provide one-stop services, from pre-sales solution planning to after-sales maintenance, to help feed companies achieve efficient, clean, and automated loading, thereby improving production efficiency.

Animal Feed Vacuum Loading Machine has been widely used in various feed production scenarios such as compound feed, concentrated feed, and premix feed. It has become a key equipment for modern feed companies to achieve clean production, automation upgrades, and quality control, providing strong support for the efficient and green development of the feed industry.