Vertical Screw Conveyors

The price of a vertical screw conveyor varies depending on factors such as material, conveying height, conveying capacity,typically ranging from $400 to $5,000.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

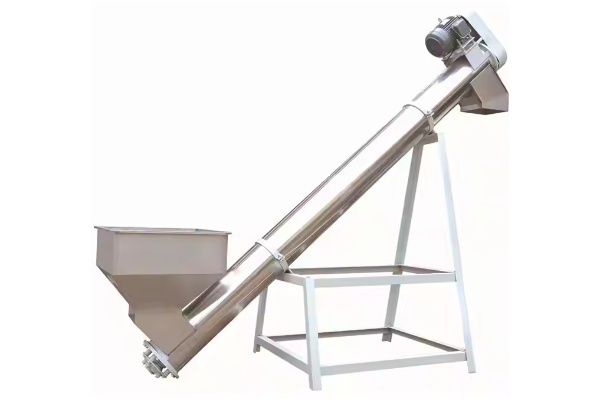

What is Vertical Screw Conveyors?

The lifting height of Vertical Screw Conveyors is generally between 1 meter and 20 meters. For general bulk materials, the handling capacity is usually between 3 m³/h and 95 m³/h (cubic meters/hour). Vertical Screw Conveyors are usually used to transport powdered, granular and small block materials from a lower position to a higher position. Its functions include material lifting, forced feeding and unloading, and its relatively compact structure makes it suitable for use in space-constrained working conditions. From the technical parameters, factors such as conveying capacity, lifting height, screw diameter, speed and material characteristics are key indicators of its performance, while its structure is mainly composed of screw body, barrel, drive device, bearing and sealing components, all of which affect the actual operation performance and applicability of the equipment.

Selecting a vertical screw conveyors requires comprehensive consideration of various factors to ensure its performance matches the application. Depending on the material characteristics and environmental requirements, different materials can be used. Carbon steel is relatively low-cost and durable, making it suitable for conveying non-corrosive materials without special hygiene requirements. Stainless steel, on the other hand, offers excellent corrosion resistance and hygienic properties. Besides the material, conveying height, conveying capacity, and material characteristics are key considerations. Furthermore, material characteristics such as bulk density, particle size, and moisture content also influence the screw pitch and speed design.

What types of vertical screw conveyors are there?

Vertical screw conveyors are specialized screw conveying equipment primarily used to lift materials vertically from low to high locations. They can be categorized by material quality and structural function, including carbon steel, stainless steel, and mobile types.

Carbon Steel Vertical Screw Conveyors

Features: Carbon steel is a common industrial material with relatively low manufacturing costs. It offers excellent mechanical strength and durability, making it suitable for conveying non-corrosive materials requiring no special hygiene requirements. It is also wear-resistant and can handle abrasive materials such as coal, ore, and sand.

Applications: Widely used in industries such as cement, building materials, chemicals, and metallurgy for conveying bulk, granular, and powdered materials.

Stainless Steel Vertical Screw Conveyors

Features: Stainless steel offers excellent corrosion resistance and can be used to convey wet, corrosive, or acidic or alkaline materials. Its smooth surface makes it easy to clean and meets the hygiene standards of industries such as food. Its clean appearance makes it suitable for environments with high environmental requirements. Applications: Widely used in industries such as food processing and fine chemicals, conveying materials requiring stringent hygiene and purity, such as flour and spices.

Mobile Vertical Screw Conveyors

Features: Highly flexible, typically equipped with wheels or a mobile base, they can be easily moved between different work areas, eliminating the need for fixed installation. They are highly adaptable, allowing for easy adjustment of conveying position and height to accommodate varying feeding and discharging requirements. They are easy to install, with a relatively compact structure, making installation and commissioning quick and simple.

Applications: Widely used in applications requiring frequent changes in conveying location, such as grain storage, agriculture, construction sites, and small factories. For example, conveying grain from trucks to warehouses or silos.

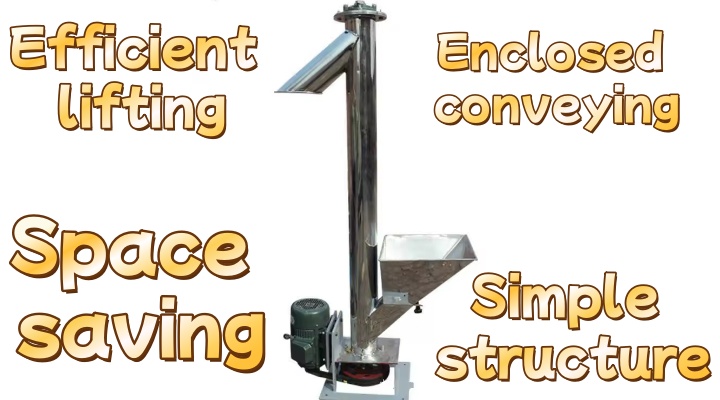

What are the advantages of Vertical Screw Conveyors?

Vertical Screw Conveyors show many advantages in specific application scenarios. It occupies a small area, and because it adopts a vertical conveying method, it effectively saves horizontal space, which is particularly beneficial for industrial production lines with limited space. The equipment structure is relatively simple, mainly composed of a screw, a cylinder, a drive device and a bearing, with a small number of parts, which helps to reduce manufacturing costs and installation difficulties. Thanks to the closed cylinder design, it has good airtightness and can effectively prevent dust or leakage during the conveying process. It is particularly suitable for handling materials with large dust or pungent odors. In addition, due to its simple structure, the equipment is relatively easy to maintain, and daily cleaning and replacement of wearing parts are direct and simple. In some designs, Vertical Screw Conveyors also have the possibility of multi-point feeding and unloading, which improves the flexibility of system operation. Finally, it is applicable to a relatively wide range of materials and can transport a variety of powdered, granular and small bulk materials, such as cement, fly ash, grain, feed and food raw materials.

Vertical Screw Conveyors Technical Data

| Model | LSY 160 | LSY 200 | LSY 250 | LSY 300 | LSY 400 | |||||||

| Metric diameter of screw (mm) | 163 | 185 | 237 | 285 | 362 | |||||||

| Rotary speed of main axis (r/min) | 308 | 260 | 200 | 170 | 170 | |||||||

| Diameter of main case(mm) | 194 | 219 | 273 | 325 | 402 | |||||||

| Max capacity (t/h) | 25 | 40 | 60 | 90 | 120 | |||||||

| Max conveying length L (m) | 15 | 18 | 25 | 25 | 25 | |||||||

| Working angle (degree) | 0~60 | 0~60 | 0~60 | 0~60 | 0~60 | |||||||

| Motor | model | L≤7M | Y132S-4 | Y132M-4 | Y160L-6 | Y180M-4 | Y180M-4 | |||||

| Power (kw) | 5.5 | 7.5 | 11 | 18.5 | 18.5 | |||||||

| model | L≥7M | Y132M-4 | Y160M-4 | Y180L-6 | Y180L-4 | Y180L-4 | ||||||

| Power ( kw) | 7.5 | 11 | 15 | 22 | 22 | |||||||

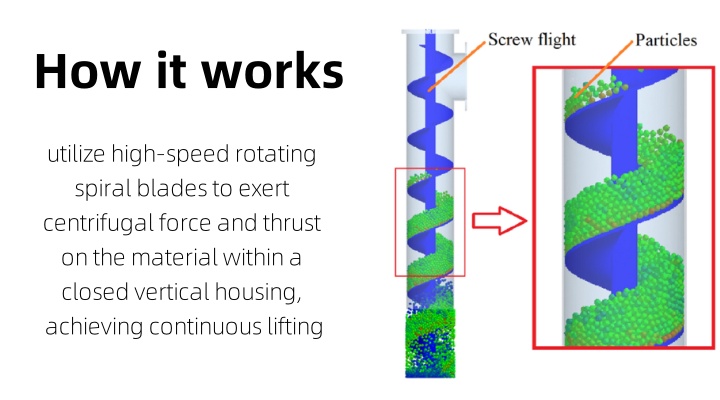

How do Vertical Screw Conveyors Work?

Vertical Screw Conveyors are used to convey materials vertically or at a steep angle from low to high locations. Their operating principle is unique and ingenious. The core of a Vertical Screw Conveyor's operation is to utilize high-speed rotating spiral blades to exert centrifugal force and thrust on the material within a closed vertical housing, achieving continuous lifting. When material enters the feed port at the bottom of the device, it falls onto the rotating spiral blades. As the spiral blades rotate at a high linear speed, they generate a strong centrifugal force, throwing the material toward the inner wall of the casing. Simultaneously, the inclination angle and rotation direction of the spiral blades generate an upward axial thrust. This thrust, combined with the friction between the material and the inner wall of the casing, prevents the material from sliding downward due to gravity. The high-speed rotation of the blades continuously pushes the incoming material into the gaps between the previous blades, forming a continuous, upward spiraling flow of material within the casing. Unlike horizontal screw conveyors, which rely on blades to propel the material along the bottom of the trough, vertical screw conveyors rely primarily on centrifugal force to maintain the material against the outer wall of the casing, combined with the thrust of the spiral blades to achieve vertical lift. This operating method ensures that the material does not accumulate at the bottom due to gravity during the lifting process and reduces relative slip between the material and the blades, thereby improving conveying efficiency. This unique operating mode makes vertical screw conveyors particularly suitable for handling free-flowing bulk materials such as grain, flour, cement, and sand. They can stably lift materials to a predetermined height, making them indispensable vertical material conveying equipment in many industrial production lines.

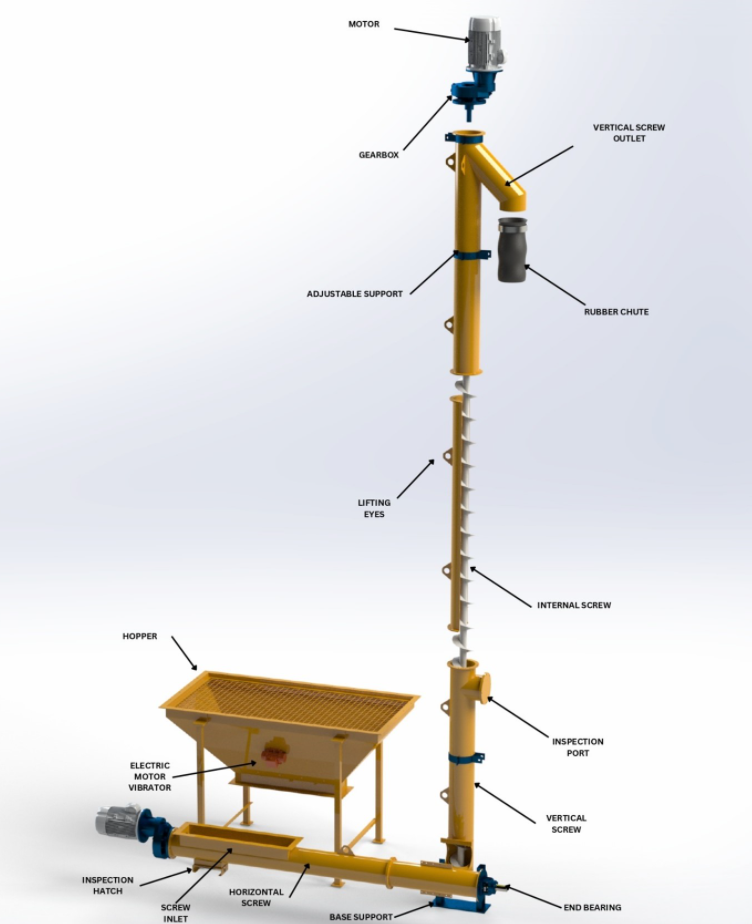

What is the structure of Vertical Screw Conveyors?

The structure of Vertical Screw Conveyors mainly consists of the following core parts. The screw is its key component, which includes a screw shaft as the core, which is usually solid or hollow, responsible for supporting the blades and transmitting power; and a spiral blade fixed on the shaft. The screw is usually wrapped in a cylinder, most of which are circular and closed, to ensure that the material does not fall when it is lifted vertically, and to maintain the internal pressure and conveying efficiency. The feed port is located at the bottom of the conveyor and is the port for the material to enter. It can be fed in by gravity or forced feeding. After reaching the preset height, the material is discharged from the discharge port at the top to connect to the silo, weighing bucket or other equipment. The drive device that provides the power for the screw to rotate is usually composed of an electric motor, a reducer and a coupling. It is generally placed at the top or bottom of the conveyor. Its power selection is related to the conveying capacity, lifting height and material characteristics. Bearings are used to support the screw shaft and reduce friction, including the bottom, top, and intermediate suspension bearings that may be set when the lifting height is large. They bear different loads and ensure operational stability. Finally, the support structure is the frame or bracket that supports the entire conveyor equipment to ensure its stable operation.

What are the product specifications of Vertical Screw Conveyors?

The technical parameters of Vertical Screw Conveyors are usually determined and adjusted according to the nature of the conveyed material, conveying capacity, lifting height and on-site working conditions. The conveying capacity is usually expressed in cubic meters per hour (m³/h) or tons per hour (t/h). Its size is affected by factors such as screw diameter, speed, screw pitch, material properties (such as bulk density, repose angle) and filling factor. For example, the conveying capacity of ordinary cement can range from 3 m³/h to 95 m³/h. The lifting height generally ranges from a few meters to tens of meters. When the height is large, special design may be required to avoid bending and deformation of the screw shaft. The screw diameter, that is, the outer diameter of the screw blade, directly affects the conveying capacity, usually ranging from 100mm to 600mm or more. The screw speed (r/min) must ensure that the material can move upward. If it is too low, it may not be lifted, and if it is too high, it will increase wear. The drive power (kW) is provided by the drive motor and is related to the conveying capacity, lifting height, material properties and equipment efficiency. Material properties include bulk density, particle size, humidity, abrasiveness, viscosity, temperature, etc., which directly affect the selection, design and material selection of the conveyor. For example, highly abrasive materials require wear-resistant materials to make the spiral blades and barrel. Common materials for the trough or cylinder are carbon steel and stainless steel. The feeding methods are divided into self-flowing (suitable for materials with good fluidity) and forced feeding (suitable for materials with poor fluidity or stable feeding).

What are the uses of Vertical Screw Conveyors?

The main function of Vertical Screw Conveyors is to achieve vertical lifting of materials. They usually work in conjunction with other conveying equipment to jointly build a complete material conveying system. Its core function is to lift materials from a lower receiving point to a higher position, such as from a ground silo or hopper to a high storage tank, weighing hopper or subsequent processing equipment. The lifting height can reach 1 meter to 15 meters or even higher. Some equipment also has a forced feeding function. Through a horizontal screw feeder or a special feeding device, it ensures that the material enters the vertical lifting section evenly and stably to prevent blockage; at the same time, its discharge port design supports multi-point unloading at high altitudes, or directly conveys to the next processing link. Compared with other vertical conveying equipment, Vertical Screw Conveyors usually occupy less space and are suitable for working conditions with limited space. In addition, its closed cylinder structure helps reduce dust and material loss, which is beneficial to environmental protection. It is especially suitable for scenes with high cleanliness requirements or for conveying toxic, flammable, and explosive materials. In some applications, through special spiral blade design or additional devices in the barrel, Vertical Screw Conveyors can also achieve auxiliary process operations such as mixing, stirring, cooling or heating of materials during the conveying process, such as ensuring constant feeding speed and further mixing of sludge in sludge treatment.

Vertical Screw Conveyors Manufacturers

Vertical screw conveyors face diverse requirements across various industries and operating conditions. One of their manufacturers' core capabilities is customization. This capability enables the equipment to precisely match specific material properties, conveying capacity, lifting height, and on-site installation conditions.

Vertical screw conveyors customization primarily involves adjusting core parameters. For example, manufacturers adjust the material, thickness, and pitch of the screw blades based on the bulk density, abrasiveness, or viscosity of the material. For applications handling corrosive materials, stainless steel screw bodies and casings are typically chosen. For conveying highly abrasive materials, wear-resistant steel or hardened blade edges are used. Secondary flexibility is the equipment's size and structure. The diameter, lifting height, and inlet and outlet locations of Vertical Screw Conveyors are not fixed, but can be precisely designed based on the customer's actual production line layout. Based on the on-site drawings provided by the customer, the manufacturer will adjust the overall height of the equipment and design a suitable inlet hopper and outlet to ensure it can seamlessly integrate into the existing production system. For example, in areas with limited space, a customized compact design can maximize space utilization; in situations where frequent movement is required, Vertical Screw Conveyors with a mobile base can meet their flexibility needs.

The selection of Vertical Screw Conveyors requires comprehensive consideration of the specific characteristics of the material, including its bulk density, particle size, abrasiveness and viscosity, which directly affect the selection and material requirements of the equipment. At the same time, clarifying the required conveying volume and lifting height is the basis for determining the screw diameter, speed and drive power. For applications that require the handling of special materials or face complex working conditions, customized equipment can be selected, and the manufacturer can adjust the spiral blades, barrel material or feeding method. In addition, our manufacturer's services are perfect, including the ability to install, debug and provide subsequent maintenance support. Choosing the right Vertical Screw Conveyors is a practical consideration to ensure the stable operation of the material conveying process.