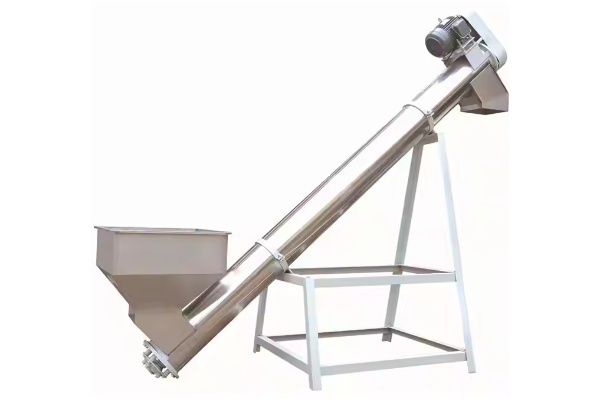

Fly Ash Screw Conveyor

The price of Fly Ash Screw Conveyor varies from US$100 to US$5,000 depending on its material, processing capacity, conveying distance, degree of automation and brand.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

What is Fly Ash Screw Conveyor?

Fly Ash Screw Conveyor is a device used to handle and transport fly ash in industrial production. This type of equipment can be divided into many types according to different designs and material selections to meet different working conditions. The amount of fly ash they can handle ranges from several tons to tens of tons per hour, and the conveying distance is usually in the range of several meters to tens of meters. Whether it is feeding from storage silos to processing equipment or transferring materials within the production line, Fly Ash Screw Conveyor provides a continuous and controllable way to convey materials.

What are the types of Fly Ash Screw Conveyor?

When selecting materials for Fly Ash Screw Conveyor, the main considerations are the abrasiveness, corrosiveness and conveying environment requirements of fly ash. Based on these factors, common material types include:

Carbon Steel Screw ConveyorCarbon steel is a common and economical material suitable for most non-corrosive or slightly corrosive fly ash conveying. It has good structural strength and can withstand large loads. It is convenient for welding, cutting and other processing.

Applicable scenarios: Usually used for dry, non-abrasive fly ash transportation without special corrosion requirements.

Notes: For fly ash with strong abrasiveness, the wear of carbon steel spiral blades and troughs will be faster, and regular inspection and replacement are required. In a humid environment, carbon steel is prone to rust, which may affect the fluidity of fly ash or cause pollution.

Wear-resistant steel screw conveyorIn view of the strong wear characteristics of fly ash, wear-resistant steel has significantly improved its hardness and wear resistance through special alloy composition and heat treatment process. It can effectively extend the service life of spiral blades and troughs and reduce downtime maintenance time.

Applicable scenarios: Mainly used for conveying fly ash with strong abrasiveness, especially in large-volume and continuous operation conditions. When wear is the main problem, wear-resistant steel is a better choice.

Notes: The cost is relatively high. The processing difficulty is slightly greater than that of ordinary carbon steel.

Stainless steel screw conveyorStainless steel (such as 304, 316L, etc.) has excellent corrosion resistance and can resist the erosion of chemicals such as acids, alkalis, and salts. The surface is smooth, not easy to adhere to materials, and easy to clean. Some stainless steel grades have good high temperature resistance.

Applicable scenarios: When fly ash contains corrosive components, or the conveying environment is humid and has strict requirements on corrosion. Occasions with high requirements for cleanliness.

Notes: The cost is significantly higher than carbon steel and wear-resistant steel. Wear resistance is usually not as good as special wear-resistant steel. For fly ash with strong abrasiveness, it may be necessary to increase the wall thickness or adopt other measures.

What are the advantages of Fly Ash Screw Conveyor?

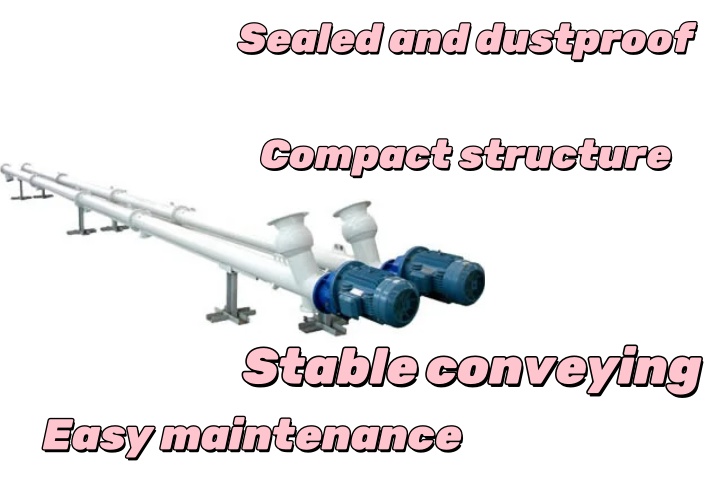

As a commonly used bulk material conveying equipment, Fly Ash Screw Conveyor has a series of significant advantages when handling fly ash, such as compact structure, good sealing, simple operation, flexible conveying direction, etc.

Compact structure and small space occupation: The screw conveyor adopts a closed trough and spiral blade design, which makes its overall structure very compact. Compared with other conveying equipment such as belt conveyors, screw conveyors occupy less space at the same conveying capacity, which is particularly important for working conditions with limited space.

Good sealing: Fly ash is a fine powder material that is prone to dust during transportation. The screw conveyor adopts a fully enclosed conveying method, which can effectively prevent dust leakage. At the same time, the closed structure also prevents rainwater or other impurities from entering the material, ensuring the quality of fly ash.

Simple operation and convenient maintenance: The structure of the screw conveyor is relatively simple and has fewer parts, which makes its operation and daily maintenance more convenient. It usually does not require complex adjustments, and daily cleaning and inspection are relatively easy, which helps to reduce operating costs and maintenance workload.

Flexible conveying direction, multi-point feeding and discharging: The screw conveyor can achieve horizontal, inclined or even vertical conveying, which gives it greater flexibility in site layout. In addition, it can also set multiple feed ports and discharge ports during the conveying process as needed, so as to achieve multi-point delivery or reception of materials, which is convenient for the optimization of process flow.

Strong adaptability and can convey high-temperature materials: The screw conveyor has flexibility in material selection, and can adapt to the transportation of fly ash of different properties, including high-temperature fly ash, by selecting suitable wear-resistant, corrosion-resistant or high-temperature resistant materials (such as heat-resistant steel). This is particularly applicable to fly ash with higher temperature that is directly conveyed from the boiler ash hopper.

Parameters of Fly Ash Screw Conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the applications of Fly Ash Screw Conveyor?

Fly Ash Screw Conveyor is mainly used for the collection, transportation, storage and connection of fly ash with other process links. It provides an easy-to-control bulk material conveying solution.

Unloading from ash hoppers or silos: Fly ash generated by thermal power plants is usually stored in large ash hoppers or silos. The screw conveyor is installed at the bottom of these storage devices and is responsible for the stable and uniform discharge of the accumulated fly ash to prepare for subsequent transportation or processing.

Short-distance horizontal or inclined transportation: Within the factory, fly ash needs to be transported short distances between different equipment or areas. For example, the collected fly ash is transported from the bottom of the dust collector to the temporary storage bin, or the fly ash from different production lines is concentrated to a mixing point. Screw conveyors are very suitable for this type of material transfer in limited space due to their compact structure and tiltable conveying characteristics.

Feeding silos or silos: After initial collection or processing, fly ash often needs to be transported to large silos or smaller silos for long-term storage or further processing. Screw conveyors can lift and deliver fly ash to these high-altitude storage facilities, and their closed nature also ensures dust-free feeding.

Used in conjunction with mixing equipment: In many industrial processes, fly ash needs to be mixed with other materials (such as water, curing agent, cement, etc.). Screw conveyors are often used to accurately control the feed amount of fly ash and stably transport it to agitators, mixers or other processing equipment to ensure the accuracy of the mixing ratio.

For metering and quantitative feeding: Screw conveyors can achieve precise control and metering of fly ash delivery through frequency conversion and other methods. This is essential for production processes that require ingredients to be batched in specific proportions, such as when preparing building materials (such as unburned bricks and concrete additives).

Fly Ash Screw Conveyor Manufacturer

Fly Ash Screw Conveyor plays an important role in handling fly ash produced by power plants, industrial boilers, etc. The selection of Fly Ash Screw Conveyor is a process that requires comprehensive consideration. First of all, it is necessary to clarify the physical properties of fly ash, including its abrasiveness, corrosiveness, temperature, humidity, and bulk density. These characteristics directly determine the selection of the main material of the screw conveyor. For example, for fly ash with strong abrasiveness, wear-resistant steel or special treatment on the blade edge is required; for fly ash with corrosiveness, stainless steel needs to be considered. Secondly, the conveying volume and conveying distance are key parameters. Different screw diameters, speeds, and inclination angles will affect the conveying capacity. At the same time, whether it is horizontal conveying, inclined conveying, or lifting, also determines the structural form and power configuration of the equipment. The manufacturer has the ability to customize, which is not only reflected in simple size adjustment, but also in providing innovative solutions according to the specific needs of customers. In addition to standard carbon steel, stainless steel and wear-resistant steel, manufacturers can provide more professional material combinations or surface treatment solutions, such as composite materials or wear-resistant coatings for specific corrosive environments. Secondly, in terms of structural design, can the manufacturer design non-standardized spiral blade forms (such as variable pitch, double spiral) or trough structures (such as U-shaped trough, tubular) according to complex site restrictions, multi-point inlet and outlet requirements, and even special material fluidity challenges.

The application scope of Fly Ash Screw Conveyor is mainly focused on solving the movement needs of fly ash within the production process. When selecting and configuring equipment, specific evaluations need to be made based on the actual physical properties of fly ash (such as particle size, moisture, abrasiveness) and on-site space limitations. The design and material selection of the equipment directly affect its operating performance in a specific environment. The formulation of a maintenance plan, including regular inspection of the wear of spiral blades and bearings, is a necessary measure to ensure the continued operation of the equipment.