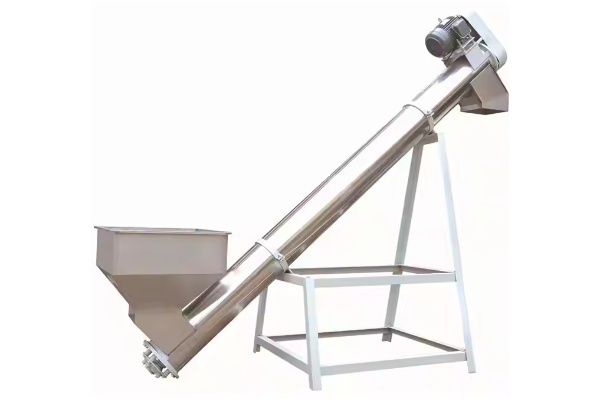

Mini Inclined Screw Conveyor

The price of Mini Inclined Screw Conveyor is affected by many factors such as volume, conveying distance, material selection, so the price ranges from US$200 to US$6,000.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

What is Mini Inclined Screw Conveyor?

Mini Inclined Screw Conveyor is a common material transfer equipment in current industrial production. The equipment can realize upward inclined conveying of materials and effectively overcome the limitation of horizontal height difference. Its design takes compactness into consideration, so that it can operate effectively in limited spaces. Depending on the specific model and configuration, Mini Inclined Screw Conveyor can handle a wide range of material volumes, ranging from several kilograms to tens of tons per hour, and the conveying distance also varies from several meters to tens of meters according to actual needs. The equipment usually adopts a closed structure, which helps to control the diffusion of materials during the conveying process. The application of this equipment provides a feasible solution for the material flow on many production lines.

What are the advantages of Mini Inclined Screw Conveyor?

Due to its unique structure and working method, Mini Inclined Screw Conveyor has shown significant advantages in many industrial fields, especially in scenarios where small-scale and precise material transportation is required. Such as high space utilization, strong adaptability, strong customizability, etc.

Compact structure and small footprint: Mini Inclined Screw Conveyor has a sophisticated design and a small cross-sectional area, which gives it a significant advantage in places with limited space. Whether it is a small area inside the factory or needs to be integrated into an existing production line, it can easily adapt and effectively utilize space.

Strong adaptability and wide range of uses: multi-angle conveying, it can realize material lifting from horizontal to a certain inclination angle (usually up to 30 degrees or even higher, and some designs can achieve vertical conveying) to meet the height difference requirements of different production processes. Material diversity, it can convey a variety of powdery, granular, small block and even some sticky or easy-to-entangle materials, such as grain, feed, chemical raw materials, cement, sludge, etc. High degree of customization, inlet and outlet positions, conveying speed, spiral blade pitch, etc. can be customized according to specific needs.

Good sealing and environmentally friendly: Fully enclosed structure, screw conveyors usually adopt fully enclosed tubular or U-shaped groove structure, which effectively prevents dust, leakage and scattering of materials during transportation.

Easy operation and maintenance: The structure of the screw conveyor is relatively simple, which makes its manufacturing and installation costs low. Due to the simple structure and fewer parts, daily inspection and maintenance are also relatively easy. For example, the quick connection shaft design is easy to disassemble and clean. Compared with other lifting equipment, screw conveyors usually have lower operating power and can achieve continuous and stable transportation, improving production efficiency.

Accurate quantitative and mixing function: By adjusting the motor speed through the frequency converter, the material conveying amount can be accurately controlled to achieve high-precision quantitative addition, which is particularly important in the batching and mixing process. In particular, the twin-screw inclined screw conveyor can effectively stir and mix while conveying materials, saving additional mixing equipment and processes.

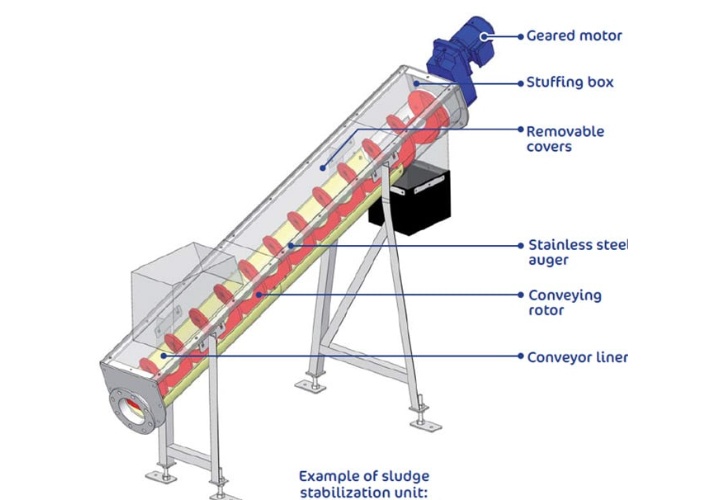

What are the structures of Mini Inclined Screw Conveyor?

Mini Inclined Screw Conveyor has a relatively simple but powerful structure and can complete the material conveying task. Its core components work closely together to ensure smooth operation of the equipment. It mainly consists of the following core components:

Screw: responsible for directly pushing the material forward. It is mainly composed of a central shaft and continuous spiral blades surrounding it. The central shaft provides solid support and transmits rotational power. The shape, pitch (the distance between adjacent spirals) and diameter of the spiral blades are carefully designed to adapt to the characteristics of different materials and the required conveying volume. Common blade types include solid spiral blades for powdery and granular materials; belt spiral blades for sticky or easily entangled materials; and segmented spiral blades that are easy to combine and replace. In addition, conical spiral blades are often used at the entrance to help the material enter more smoothly. In terms of material selection, the screw body is usually made of carbon steel, food-grade stainless steel, or alloy steel in special wear-resistant and corrosion-resistant environments.

Conveyor trough: The conveyor trough is the outer shell that wraps the screw body and carries the material. Its shape is mainly divided into two types: U-shaped trough and tubular (round tube). The U-shaped trough design is easy to clean and maintain, and is more suitable for conveying materials with larger particles; while the tubular conveyor trough can effectively prevent dust spillage and material contamination with its excellent sealing performance, especially for powdery, fine-grained materials or occasions with strict environmental requirements. The material enters the conveyor trough through the inlet, moves along the trough body under the push of the spiral, and is finally discharged from the outlet. The position of the inlet and outlet can be flexibly designed according to the actual process flow. The material of the conveyor trough is usually consistent with the spiral to ensure overall compatibility and durability.

Drive device: mainly composed of motor, reducer and coupling. As the power source, the motor usually adopts a three-phase asynchronous motor, and special types such as explosion-proof motors can also be selected according to the application scenario. The function of the reducer is to reduce the high speed of the motor to the working speed required by the spiral, while providing sufficient torque. Common types of reducers include gear reducers and cycloidal pinwheel reducers. The coupling is responsible for connecting the motor, reducer and spiral shaft to ensure effective power transmission. For applications that require precise control of the conveying volume, the equipment will also be equipped with a frequency converter to accurately control the speed of the spiral and the material flow by adjusting the motor speed.

Parameters of Mini Inclined Screw Conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the applications of Mini Inclined Screw Conveyor?

Mini Inclined Screw Conveyor plays a key role in many material conveying scenarios with its unique advantages. The core of its application is to solve how to lift and convey materials in a controlled manner within a limited space.

Material conveying and lifting: Whether it is feeding raw materials into a mixer or reactor, or lifting processed products to a packaging line, the Mini Inclined Screw Conveyor can effectively overcome the limitations of height differences. It can handle materials in various states, including powders, fine particles, crystals, and even some small block materials. Its closed design ensures that the material is not contaminated by the outside world during the conveying process, and also avoids dust, which is particularly important for scenes that need to keep the environment clean or convey sensitive materials.

Quantitative feeding and precise control: Mini Inclined Screw Conveyor performs well in precise metering and quantitative feeding. By adjusting the speed of the spiral, the material conveying amount can be accurately controlled, thereby achieving precise batching and addition. This is critical in many process flows, for example, when mixing multiple ingredients, ensuring that each ingredient is added accurately in proportion; or in a continuous production line, feeding materials to the next link at a fixed flow rate. This capability greatly improves the level of production automation and the stability of product quality.

Process flow integration: Mini Inclined Screw Conveyor is very suitable for integration into complex production lines and automated equipment due to its compact size and flexible installation method. It can serve as a bridge connecting different process units, such as conveying materials from a dryer, grinder or screener to the next processing unit. Its design can be customized according to the on-site space and process requirements, including the location of the inlet and outlet, the conveying angle, etc., so that it can be seamlessly integrated into the existing system and optimize the overall process flow.

Buffering and continuous feeding: In some cases, Mini Inclined Screw Conveyor can also be used for short-distance caching of materials or as a continuous feeding device. For example, it can receive materials from an intermittent batch processing device and then feed them into a continuously running device at a constant speed, thereby balancing the rhythm of the previous and next processes and ensuring the smoothness of production.

Mini Inclined Screw Conveyor has a series of practical features that make it suitable for a variety of industrial scenarios. First, its structure is relatively straightforward, which is convenient for on-site installation and layout. Second, the equipment has a certain material adaptability, can handle materials in different physical states, and supports lifting and conveying at a specific angle. Its closed design can effectively manage materials during the conveying process and reduce the impact of external factors on materials. In addition, the equipment also considers convenience at the operational level, and daily inspection and maintenance are relatively straightforward. These features make Mini Inclined Screw Conveyor a viable option in actual production environments where material transfer and lifting are required.