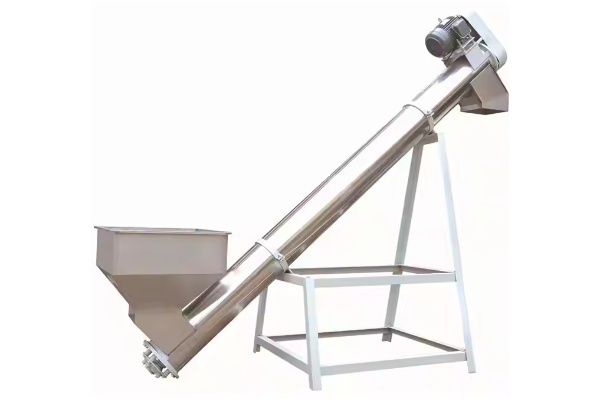

Ethylene powder screw conveyor

The price of Ethylene powder screw conveyor varies greatly depending on factors such as its type, material, size, and degree of automation.Its price range is between $200 and $6,000.

Rotation speed: 45-70 R/Min

Size (L*W*H): 2000*200 * 220mm/customizable

Frame material: carbon steel/stainless steel

Power: 0.4kW-22kW

Voltage: 220V/380V/415V

Frequency: 50/60Hz

What is Ethylene powder screw conveyor?

Ethylene powder screw conveyor are designed for conveying powdered materials. Depending on the working conditions, these conveyors can be divided into two basic types: shafted and shaftless, each with its own structural characteristics. Materials can be selected from carbon steel or stainless steel to accommodate varying material properties and environmental requirements. Furthermore, their operating angles can be flexibly adjusted, from horizontal to inclined, to accommodate complex spatial layouts. The conveying capacity of a single unit typically ranges from several to tens of tons per hour, and the conveying distance can reach tens of meters, meeting the material transfer needs of conventional production lines.

What are the types of ethylene powder screw conveyors?

Ethylene powder is a lightweight, easily volatile material, requiring special consideration when selecting a screw conveyor to ensure smooth conveying. Ethylene powder screw conveyors primarily come in the following types, with options tailored to your needs:

Classification by the presence or absence of a central shaft

Shafted screw conveyors: This is the most common type. The spiral blades rotate around a central shaft, propelling the material forward along the trough. They offer a simple structure and low cost, making them suitable for conveying a variety of powdered and granular materials. However, ethylene powder tends to adhere to the central shaft, causing material accumulation or blockage, especially when handling highly humid or sticky materials. Furthermore, the presence of a central shaft reduces the material's flow area, reducing conveying efficiency.

Shaftless screw conveyors: These conveyors lack a central shaft and instead propel the material through the rotation of the screw itself. This lack of a central shaft prevents material entanglement and blockage, making them particularly suitable for conveying materials prone to adhesion and entanglement, such as ethylene powder. Furthermore, their larger conveying channel improves conveying efficiency and handling capacity.

Classification by Material

The material used for a screw conveyor should be selected based on factors such as the material's corrosiveness, abrasiveness, and hygiene requirements. Commonly used materials for ethylene powder include:

Carbon steel: Low cost and high strength, suitable for general industrial conveying. However, it is not suitable for ethylene powder containing corrosive substances or for applications with strict hygiene requirements (such as food-grade).

Stainless steel: Features excellent corrosion resistance and hygienic properties, making it suitable for applications with stringent hygiene requirements, such as food-grade ethylene powder production lines. Numerous stainless steel grades are available, such as 304 and 316, and selection can be tailored to specific corrosion resistance requirements. Other special materials: For example, wear-resistant alloy steel may be used under certain special operating conditions to extend equipment life.

Classification by inclination angle

Screw conveyors can be categorized into horizontal, inclined, and vertical conveying types based on their inclination angle.

Horizontal screw conveyors: These conveyors are installed horizontally and are the most widely used type. They offer high conveying efficiency and long conveying distances.

Inclined screw conveyors: These conveyors transport materials upward or downward at a certain inclination angle. When conveying ethylene powder, the inclination angle should generally be kept to a minimum, typically between 0° and 20°. Excessive inclination may cause the material to fall back, reducing conveying efficiency.

Vertical screw conveyors: These conveyors have a vertically installed screw body and are used to transport materials upward to a higher height. They occupy a smaller footprint and can achieve high-level conveying. However, their energy consumption is relatively high, and their conveying capacity is lower than that of horizontal and inclined conveyors. Therefore, when conveying ethylene powder, they are generally only used for short vertical lifts.

What are the advantages of an ethylene powder screw conveyor?

In the material conveying industry, ethylene powder presents some challenges in equipment selection due to its light weight, high airflow, and somewhat sticky nature. However, screw conveyors, particularly shaftless screw conveyors, offer significant advantages in handling ethylene powder due to their unique design.

Avoiding material blockage and entanglement: With shafted screw conveyors, the central shaft easily allows sticky or entangled materials like ethylene powder to adhere or accumulate, reducing conveying efficiency or even causing complete blockage. Shaftless screw conveyors, however, lack a central shaft, providing a completely open conveying channel that effectively prevents material entanglement and blockage, ensuring continuous and stable conveying.

Improving conveying efficiency and capacity: The shaftless design not only eliminates blockage issues but also significantly improves conveying efficiency. The larger cross-sectional area allows for more material to be handled, thereby increasing conveying capacity. This is crucial for production lines that require high-volume, high-efficiency conveying of ethylene powder.

Simple structure and easy maintenance: While the manufacturing process for shaftless screw conveyors is relatively complex, their overall structure is straightforward, consisting solely of a screw body, a U-shaped trough, and a drive mechanism, with no vulnerable parts such as intermediate bearings. This significantly reduces the complexity and frequency of maintenance, minimizes downtime, and improves production line reliability.

Enclosed conveying, safer: Screw conveyors typically utilize a fully enclosed U-shaped trough or tubular design. This enclosed structure effectively prevents dust contamination caused by the flying of ethylene powder during conveying, improving the working environment. It also prevents moisture and contamination of the material by external impurities, ensuring its purity.

Adaptable and flexible layout: Screw conveyors can be customized to meet site requirements, enabling horizontal, inclined, and even vertical conveying. For factories with limited space or where ethylene powder needs to be conveyed at varying heights, screw conveyors offer flexibility and can easily adapt to various complex process layouts.

Parameters of Ethylene Powder Screw Conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

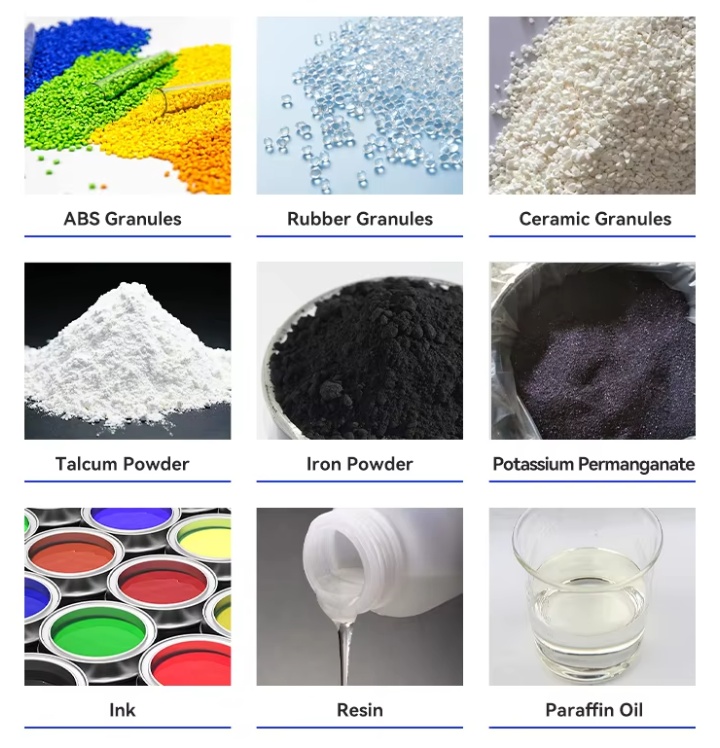

What materials are suitable for Ethylene Powder Screw Conveyors?

The Ethylene Powder Screw Conveyor is primarily designed to address the challenges posed by the unique physical properties of ethylene powder. It is not only suitable for ethylene powder itself, but its design and advantages also make it an ideal choice for handling a range of similar materials. In addition to ethylene powder, this type of conveyor is particularly suitable for conveying the following materials:

Lightweight, airborne powders: These materials are prone to generating dust and polluting the environment during conveyance. The fully enclosed design of a screw conveyor effectively addresses this problem, for example, plastic powders such as PVC powder and polypropylene powder.

Materials with a certain degree of adhesion: Certain materials tend to clump and adhere in humid or high-temperature environments, leading to blockage in conveying pipes. Shaftless screw conveyors, with their central shaftless design, effectively prevent entanglement and adhesion of materials, such as activated carbon powder and some chemical raw materials.

Irregular, lumpy, or fibrous materials: Shaftless screw conveyors are a better choice for materials that tend to entangle on the central shaft, such as certain food processing waste and wood chips.

Materials with high hygiene requirements: In industries such as food, materials must maintain high purity to avoid contamination. Stainless steel screw conveyors are easy to clean and can meet stringent hygiene standards, such as for starch, flour, and condiments. Overall, the Ethylene Powder Screw Conveyor, with its anti-clogging, anti-airflow characteristics and high efficiency, is a versatile solution for handling a wide range of powdered, granular, and small bulk materials. As long as the material's particle size, adhesiveness, and corrosiveness are within the equipment's design parameters, this type of conveyor can be considered.

What are the Applications of the Ethylene Powder Screw Conveyor?

The Ethylene Powder Screw Conveyor is a versatile device designed to reliably handle a wide range of powdered and granular materials. Its application lies in safely and cleanly conveying a variety of lightweight, airy, sticky, or demanding materials. The chemical and plastics industries are a core application area for the Ethylene Powder Screw Conveyor. It is widely used to convey various powdered raw materials in the production of plastics, resins, rubber, and chemical fibers. For example, it can transport PVC powder, polyethylene (PE) powder, and polypropylene (PP) powder from large silos and tanks to downstream mixing, extrusion, or packaging equipment. The fully enclosed conveying method effectively controls dust and prevents moisture and contamination of the material, ensuring a clean production environment and high product quality. Screw conveyors also play a vital role in the construction industry. They can be used to transport cement, lime powder, mineral powder, gypsum powder, and putty powder, moving these materials from storage tanks to mixers or packaging lines. Conveyors can operate at a specific angle to accommodate conveying needs at varying heights, streamlining production processes. In short, the ethylene powder screw conveyor has a wide range of applications. It's not just specialized equipment for conveying ethylene powder; it's also a clean, reliable, and versatile conveying solution suitable for any industry requiring the safe handling of powdered or granular materials.

As a fundamental material conveying tool, the ethylene powder screw conveyor plays a specific role in practical applications. Its operation relies on the rotation of a motor-driven screw, achieving continuous material movement. The design and selection of the equipment directly impact its suitability for a specific production process and require comprehensive consideration of the material's physical properties, environmental conditions, and specific process requirements. Maintenance primarily involves regular inspection of transmission components and cleaning of the conveyor trough.