Screw Conveyor Blades

The price of screw conveyor blades varies greatly depending on the material, diameter, pitch, thickness, and degree of customization, ranging from $5 to $1,000.

Material: Carbon Steel/Stainless Steel

Outer Diameter: Up to 800mm

Strip Width: Up to 150mm

Thickness: 2-8mm

Dimensions: Customizable

Applicable Industries: Screw Conveyors/Energy/Mining

What is Screw Conveyor Blades?

Screw Conveyor Blades are the core components of screw conveyors. Their primary function is to convey materials horizontally, obliquely, or vertically. Blade designs vary, with common types including solid, belt, paddle, and segmented. Each type has its own specific application scenarios. For example, solid blades are suitable for general conveying of powdered and granular materials, while belt blades are more suitable for sticky or easily agglomerated materials. Furthermore, the choice of blade material, such as carbon steel, stainless steel, or wear-resistant alloy, directly affects its suitability and service life under specific operating conditions.

What are the types of screw conveyor blades?

Screw conveyor blades are the core components of screw conveyors, and their design directly affects the conveyor's performance and range of applications. Depending on the material properties and conveying requirements, blades are primarily categorized into three types: solid blades, paddle blades, and belt blades.

Solid blades

Solid blades are the most common and basic blade type. They are characterized by a continuous spiral shape, with the pitch (the distance between adjacent blades) typically equal to the blade's outer diameter. This design generates uniform and stable thrust during conveying, resulting in high conveying efficiency. Its simple structure, mature manufacturing process, relatively low cost, and high versatility make it suitable for conveying most non-sticky, small-particle, or powdery materials, such as cement, sand, grain, and flour.

Paddle Blades

Paddle blades consist of a series of independent blades mounted at an angle to the screw shaft, without forming a continuous spiral surface. The advantage of this type of blade lies in its stirring and mixing capabilities. While conveying the material, the blades provide thorough agitation, preventing clumping and ensuring uniform mixing. This is crucial for processes requiring mixing, heating, or cooling.

Applications: Suitable for materials that require simultaneous mixing, stirring, or loosening, such as certain chemical raw materials, food ingredients, or wet clay that tends to clump.

Ribbon Blades

Ribbon blades lack a continuous spiral surface, but instead consist of one or more spiral ribbons with a large gap between the ribbons and the central axis. This blade is designed to handle highly viscous and easily adhered materials. The belt-like structure reduces the contact area between the material and the screw shaft, effectively preventing it from adhering to the shaft and reducing the risk of clogging. This design also reduces shear forces on the material, making it suitable for conveying fragile or shear-sensitive materials.

Application: Designed for conveying highly viscous and easily adhered materials such as tar, syrup, and mud.

What are the advantages of screw conveyor blades?

Different types of screw conveyor blades are designed to solve specific material conveying challenges. Each blade offers unique advantages that optimize conveying efficiency and process flow, ensuring continuous and stable conveying. The following are the advantages of each blade type:

Solid blades: The continuous spiral surface generates a constant and stable thrust on the material, resulting in high conveying efficiency. They feature a simple structure, mature manufacturing technology, low cost, and easy installation and maintenance. They are highly versatile.

Variable pitch blades: Prevent clogging. The variable pitch design effectively prevents material accumulation at the feed inlet, especially with large feed rates. Improves conveying efficiency by evenly distributing materials within the spiral trough, increasing the conveyor's fill rate and overall efficiency.

Paddle-type blades: Provides mixing and stirring capabilities. The paddles thoroughly agitate the material during conveying, making them ideal for materials that require mixing and stirring. Prevents agglomeration. The agitation of the paddles effectively loosens the material, preventing it from clumping during conveying. Suitable for specialized processes, such as heating or cooling, the paddles provide better contact with the material, improving heat exchange efficiency.

Strip-type blades: Prevents clogging. The gap design significantly reduces the contact area between the material and the spiral shaft, effectively preventing high-viscosity materials (such as syrup and tar) from adhering to the shaft and reducing the risk of clogging. Reduces shear forces. This design minimizes the shearing effect on the material.

Serrated blades: Provides a crushing and loosening function. The serrated edges cut, crush, and loosen the material during conveying, making them particularly suitable for conveying materials with a certain degree of moisture or prone to agglomeration. Improves flowability by breaking up agglomerates, enhancing material flow and improving overall conveying efficiency.

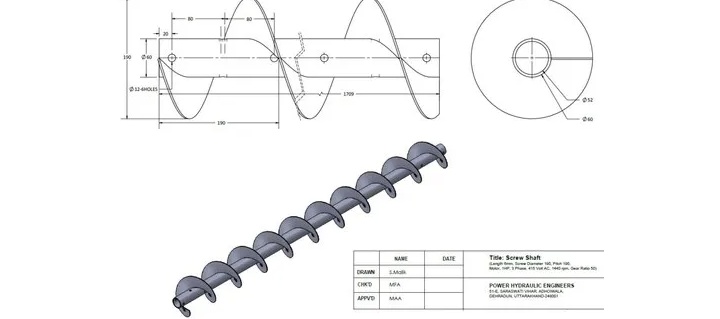

What are the structures of screw conveyor blades?

The structure of a screw conveyor blade primarily consists of two parts: the blade itself and a central shaft. The blade is secured to the central shaft by welding or other means, forming a single, integrated unit. Although the structures of different blade types vary, their basic components and connection methods are similar.

Solid blade: The blade is constructed from a continuous, spirally shaped piece of sheet metal. The entire blade resembles a giant screw, uninterrupted from beginning to end. The inner edge of the blade is typically securely welded to the central shaft using a continuous weld process.

Strip blade: The blade consists of one or two spirally shaped strips of sheet metal. Unlike solid blades, these strips lack an internal helical surface, and a clear gap exists between the strip and the central shaft. The strip is connected to the central shaft at a specific angle and spacing using structural members such as brackets or spacers.

Paddle blade: The blade is not continuous, but rather consists of a series of individual, angled blades. Each blade is a separate component, mounted on the central shaft at a specific spacing and angle. Each individual blade is welded or mechanically secured to the central shaft.

Variable-pitch blades: The pitch (the distance between adjacent blades) is uneven. The pitch gradually increases from the inlet to the outlet. Similar to solid blades, continuous welding is typically used.

In general, the structural design of screw conveyor blades is the result of comprehensive consideration of material characteristics, conveying objectives, and operating conditions. Each design offers unique advantages to meet diverse conveying needs.

What are the applications of screw conveyor blades?

Screw conveyor blades come in a variety of types, each with its own specific application. Different blade types are used to handle materials with different characteristics, ensuring a continuous and stable conveying process. The following are some common applications of screw blades:

Solid blades: Solid blades are the most widely used type. Their continuous spiral structure provides stable propulsion for the material. This type of blade is most suitable for conveying fluid, non-sticky materials. These include powders and granular materials such as cement, lime, flour, grain, and plastic pellets. Dry bulk materials such as sand, coal powder, and wood chips are also suitable. Variable-pitch blades: The pitch of variable-pitch blades gradually increases from the feed inlet to the discharge outlet. This design primarily addresses feed inlet blockage and improves conveying efficiency. For high-volume applications, concentrated feeding prevents material accumulation at the feed inlet. It is also suitable for conveying materials that tend to compact under concentrated pressure.

Paddle blades: Paddle blades consist of independent blades whose primary function is to simultaneously mix, agitate, or loosen materials. For material mixing, they are suitable for applications requiring uniform mixing of different ingredients, such as chemical raw materials and food ingredients. For materials with a certain degree of moisture or prone to clumping, the agitation provided by the paddles effectively prevents clumping. For heating or cooling applications, when heat treatment is required, the paddles ensure full contact between the material and the heat exchange medium, improving efficiency.

Strip blades: The core advantage of strip blades lies in the gap between the spiral band and the central axis, making them ideal for handling highly viscous and easily adhered materials. This design effectively reduces the risk of material adhering to the blades and central shaft. Because the ribbon-shaped blades exert less shearing force on shear-sensitive materials, they are also suitable for conveying fragile materials or materials that need to maintain integrity.

Screw Conveyor Blade Manufacturers

Screw conveyor blades, as core components of screw conveyors, directly impact the overall conveying efficiency and material handling performance of the machine. To meet the specific conveying needs of various industries and materials, screw conveyor blade manufacturers offer customized services. This customized production model allows manufacturers to tailor blades to meet specific operating conditions based on specific customer requirements. Manufacturers can design and manufacture different blade types based on specific customer needs, such as material characteristics, conveying capacity, and equipment dimensions. Material customization is also available, with a variety of material options available, including carbon steel, stainless steel, and wear-resistant steel, depending on the material's abrasiveness, corrosiveness, and operating environment. Customized dimensions allow us to produce blades with varying diameters, thicknesses, pitches, and rotation directions to suit various screw conveyor models. Customized blade types allow us to customize various blade types, including solid blades, variable-pitch blades, paddle-style blades, ribbon blades, and serrated blades, based on customer requirements. Surface treatment services include painting, polishing, and galvanizing to enhance corrosion resistance and aesthetics. Some manufacturers also offer technical consulting services to assist customers in selecting the most appropriate blade type and parameters to ensure conveyor performance. When selecting a manufacturer, it's important to consider their production process, technical expertise, material quality, and after-sales service capabilities. Understanding these factors helps ensure that customized blades meet the needs of your application.

Screw conveyor blades are critical components in the material conveying process, ensuring stable movement of materials within pipes or troughs. The blade's geometric characteristics, including pitch, diameter, and thickness, directly impact material movement and conveying capacity. In actual applications, users need to select the appropriate blade type and material based on the physical properties of the material (such as density, particle size, and viscosity) and the conveying environment. For example, stainless steel blades are a common choice for corrosive materials, while wear-resistant alloys are required for highly abrasive materials.