Food-Grade Vacuum Loading Machine

Food-Grade Vacuum Loading Machine has the advantages of fully sealed, dust-free pollution, less material loss and high degree of automation. It can not only avoid material pollution caused by manual contact, but also adapt to different industries' different needs for cleanliness, explosion-proofness, and conveying efficiency.

Belt material: stainless steel

Voltage: 80V / Customizable

rame material: 304, 316 stainless steel

Conveyor capacity: 10 kg - 10 tons/hour

Length: Customizable, 1-100 meters

Conveyor materials: granular and powdery materials

Suitable materials: flour, milk powder, sugar, seasoning powder, sugar powder, coffee powder, tea powder, chili powder, curry powder

What is a Food-Grade Vacuum Loading Machine?

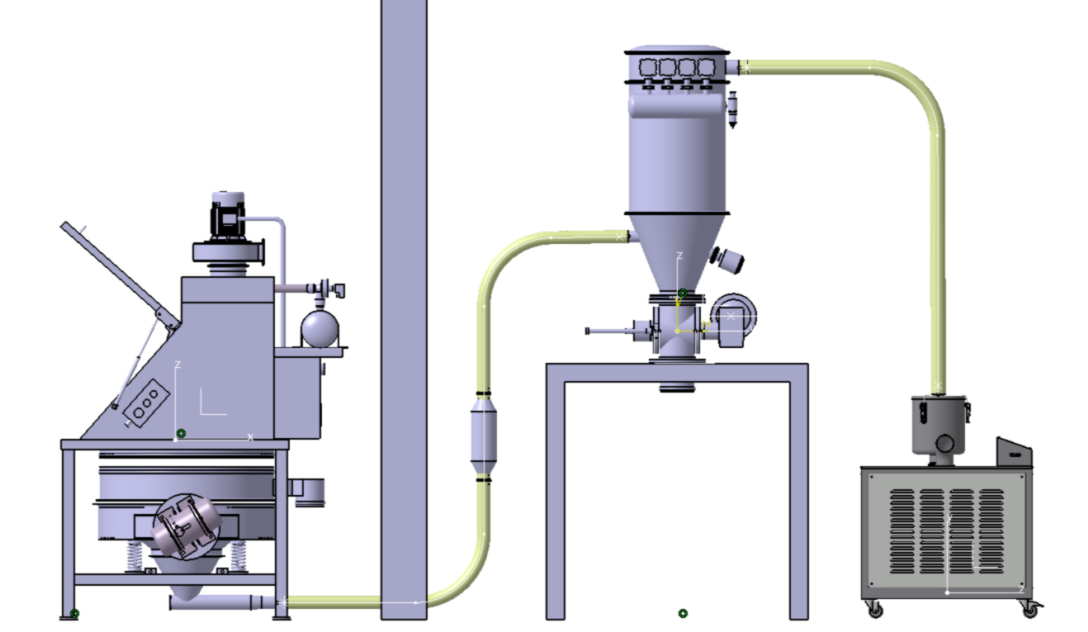

Food-Grade Vacuum Loading Machine is a closed-loop material conveying device designed specifically for the food industry. Utilizing the principle of negative pressure adsorption, it automates the transfer of powders and granular materials such as flour, milk powder, sugar, and seasoning powder. Compared to conventional vacuum loaders, this machine has stricter requirements regarding materials, cleanliness, and safety standards. All material-contacting parts are made of food-grade stainless steel, and the interior is mirror-polished to eliminate material residue. The machine also provides a fully enclosed conveying system. A variety of models are available to meet the conveying and loading needs of various industries.

To address challenges such as flexible mobility, material discharging, and space constraints, our Food-Grade Vacuum Loading Machines offer multiple customization options. Equipped with high-strength, silent rollers, the machine can be flexibly moved within flour mills and milk powder workshops, accommodating alternating loading at multiple stations. The discharging port can be customized to fit your mixer or packaging machine interface in round, square, or flanged configurations, ensuring seamless integration. The overall height of the machine can also be adjusted to suit the floor height and silo location, offering flexible design options from 1.2 meters to 3 meters.

What types of Food-Grade Vacuum Loading Machines are available?

Our Food-Grade Vacuum Loading Machines primarily include double disc valve sealed, manual lift, and continuous discharge types, specifically designed for high hygiene standards, flexible material feeding, and large-scale continuous production.

Double Disc Valve Vacuum Loader:Utilizing an alternating upper and lower disc valve structure and food-grade PTFE valve discs, it achieves a highly leak-tight vacuum suction and discharge cycle. Its advantages lie in its zero-leakage sealing performance, wide material compatibility, and high-precision quantitative conveying capabilities.

Manual Lift Vacuum Loader:Equipped with a manual lift mechanism and a mirror-polished stainless steel hopper, it allows for flexible adjustment of the feeding height and quick docking with production equipment. This model offers flexible operation, easy cleaning, and economical practicality, requiring no electrical power for complete feeding operations.

Continuous Discharge Vacuum Loader:It utilizes a rotary valve or a two-stage air lock valve structure to achieve simultaneous vacuum suction and continuous discharge. Its significant advantages include seamless continuous operation, a 30% reduction in energy consumption, and an anti-bridging design, significantly improving conveying efficiency.

What are the advantages of a Food-Grade Vacuum Loading Machine?

The Food-Grade Vacuum Loading Machine is a hygienic conveying equipment designed specifically for the food, health supplement, and pet food industries. It utilizes vacuum pressure to ensure the transport of powdered and granular materials without contamination, residue, or cross-contamination.

Flexible Customization: Customizable anti-sticking piping and pulse backflush cleaning systems are available for different materials, including powders and granules. It supports multi-hopper switching and integrated weighing, meeting the formulation-based production needs of industries like baking, dairy, and condiments.

Fully Enclosed Pipeline Design: The equipment utilizes sealed stainless steel piping, completely isolating materials from the outside world during conveying, preventing cross-contamination from dust from powdered ingredients like flour, powdered sugar, and milk powder.

Residue-Free Conveying Technology: The interior of the pipe is polished to reduce material adhesion, and a pulse backflush cleaning system automatically removes residual material.

Adaptable to Complex Working Conditions: Vertical conveying is possible, with a maximum lifting height of 20 meters, meeting the needs of multi-story factories. Long-distance conveying, with a single pipe length of up to 50 meters, reduces transfers.

Working Principle of the Food-Grade Vacuum Loading Machine

The food-grade vacuum loader utilizes the core operating principle of negative pressure adsorption. A vacuum pump extracts air from the enclosed conveying system, creating a stable negative pressure environment. Due to the pressure difference between the outside atmospheric pressure and the system's negative pressure, food materials such as flour, milk powder, and sugar are drawn from the storage silo into the conveying pipeline. The mixture then enters a separation hopper, where it passes through a food-grade filter for separation. The material then falls by gravity into target equipment such as mixers and packaging machines, and the filtered, clean air is discharged from the system.

Food-Grade Vacuum Loading Machine Technical Parameters

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

Main Components of a Food-Grade Vacuum Loading Machine

The Food-Grade Vacuum Loading Machine features an all-stainless steel, enclosed structure, including a vacuum system, filtration unit, conveying piping, and an intelligent control system. It is designed specifically for contamination-free conveying in the food industry.

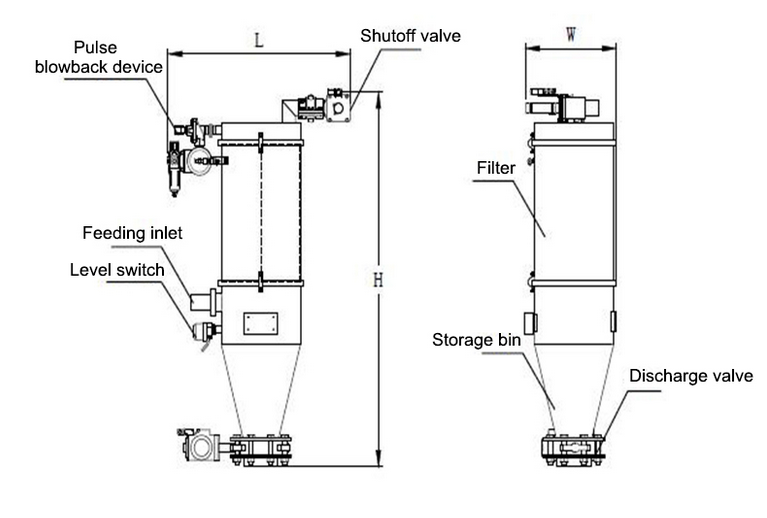

Vacuum Generation System:As the core power source of the equipment, it typically consists of a vacuum pump or vacuum generator, responsible for creating a stable negative pressure environment within the conveying system. Food-grade models often use an oil-free vacuum pump or a vacuum generator driven by clean compressed air to provide continuous power for material suction and conveying.

Food-Grade Conveying Components:Including the suction nozzle, conveying piping, and connectors, all are constructed of stainless steel with a mirror-polished interior. This design prevents bacterial growth from remaining material and reduces powder absorption.

Air-Material Separation Device:Composed of a separation hopper and a food-grade filter element. After entering the hopper with the airflow, the material passes through the filter element to separate the air and material. The material settles by gravity, and the clean air is filtered and discharged.

Control System:Based on a PLC system, it features a touchscreen for automated operation. Parameters such as conveying volume, start and stop time, and cleaning cycle can be preset, and it supports linkage with other equipment on the production line to achieve accurate feeding.

What are the application scenarios of the Food-Grade Vacuum Loading Machine?

Due to its unique characteristics, the Food-Grade Vacuum Loading Machine is widely used in all aspects of food processing, from raw material processing to finished product packaging, covering the conveying needs of powdered, granular, viscous, and liquid materials.

The baking industry: In bakeries and cake production lines, flour needs to be transported from underground storage tanks across floors to the mixing room. Vacuum loaders use sealed pipes to prevent dust generation. Each unit has a conveying capacity of 6 tons per hour, achieving efficiency eight times that of manual labor. Equipped with a cyclone separator, the flour loss rate is less than 0.5%.

Dairy processing: Milk powder needs to be transported from the drying tower to the packaging machine, where it must be protected from moisture absorption and oxidation. The vacuum loaders use nitrogen protection to control the oxygen content below 0.5%. Made of 316L stainless steel with an electropolished finish, they meet food contact standards and maintain a constant conveying temperature to prevent nutrient loss.

Seasoning production: More than 10 spices must be conveyed to the mixer according to recipe. The vacuum loaders utilize multi-way valve switching technology to automatically feed multiple cans from one machine. Transfer times can be preset, increasing efficiency tenfold compared to manual labor.

Candy and chocolate manufacturing: Powdered sugar needs to be transported from the storage silo to the sugar boiling pot. The vacuum loaders utilize explosion-proof motors and explosion vents, and electrostatic grounding devices reduce the static voltage in the pipeline from 15kV to below 0.5kV.

Beverage and alcohol production: In soluble tea and instant coffee production lines, tea and coffee powders need to be conveyed to packaging machines. Vacuum loaders equipped with sterile air filtration systems ensure microbiological indicators meet standards, and the metal-free conveying process prevents foreign matter contamination.

Material Grades of Food-Grade Vacuum Loading Machines

Food-grade vacuum loaders are available in both 304 and 316 stainless steel. 304 stainless steel meets general food conveying requirements, while 316 stainless steel, enhanced with molybdenum, specializes in highly corrosive environments, providing reliable support for high-end food production.

304 stainless steel :is an economical and practical choice for food-grade vacuum loaders, offering excellent corrosion resistance and mechanical properties. It is suitable for conveying neutral or slightly acidic materials such as flour, milk powder, and grains. It is low-cost and meets the hygienic requirements of most food production processes.

316 stainless steel: with its added molybdenum, exhibits superior corrosion resistance and is particularly suitable for handling acidic foods, high-salt materials, or applications requiring high-temperature cleaning and sterilization. Although the cost is 30%-50% higher than 304 stainless steel, it offers a longer service life and lower maintenance requirements.

Food-Grade Vacuum Loading Machine Customer Case Studies

Three case studies, including aseptic conveying in milk powder factories, moisture-proof feeding in condiment factories, and precise ingredient mixing in health supplement factories, demonstrate how equipment can address pain points in the food industry, such as dust pollution and cross-contamination, improving production efficiency and ensuring product safety through compliant design.

Baked Goods Industry:Large bakery factories have long faced issues such as inefficient manual feeding and severe dust pollution. With the introduction of a Food-Grade Vacuum Loading Machine, materials are conveyed through sealed 304 stainless steel pipes using 0.5-0.8 MPa negative pressure airflow. Combined with an intelligent backflush system and variable frequency control, the machine consumes only 1.2 kW/h of electricity to transport one ton of flour, a 40% reduction compared to previous pneumatic conveying methods. The machine's automated integration with mixing equipment has increased daily flour processing capacity from 50 to 80 tons.

Dairy Products Industry:Milk powder manufacturers maintain extremely strict product quality control. In the milk powder packaging process, raw materials were previously manually transported to the packaging machine's silo, which could easily cause secondary contamination. This company implemented a food-grade vacuum loading machine, which provides a fully enclosed conveying system that eliminates external contamination and precisely controls the loading speed and quantity.

Seasoning Industry:A variety of spices need to be conveyed to mixing equipment. Manual spice conveying previously resulted in material separation and uneven mixing, and the spices were easily deteriorated by environmental influences. The introduction of a food-grade vacuum loading machine, which uses a vacuum generator to generate a high vacuum, eliminates material separation and ensures uniformity of the mixed ingredients.

Food-Grade Vacuum Loading Machine Price

Prices for the food-grade vacuum loading machine start at $2,300. Made of 304/316 stainless steel with a mirror polish, it supports CIP online cleaning and automated control. Pricing varies depending on material grade, conveying capacity, and special features such as explosion-proof/aseptic features. This product provides safe and dust-free conveying solutions for foods like milk powder and seasonings. Due to individual manufacturer requirements, pricing may vary. If interested, please contact us for a detailed price list.

Through technological innovation and process optimization, the Food-Grade Vacuum Loading Machine not only addresses the pollution, waste, and efficiency challenges of traditional conveying methods, but also serves as critical infrastructure for promoting high-quality development in the food industry. For food companies, choosing a vacuum loader that meets GMP standards is both a necessary requirement for fulfilling social responsibility and a strategic choice for enhancing market competitiveness.