Milk Powder Vacuum Loading System

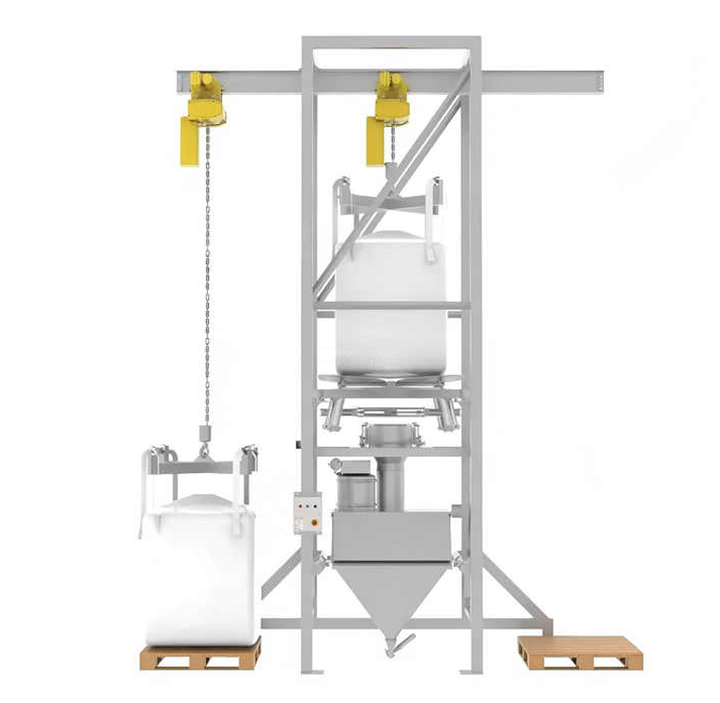

Milk Powder Vacuum Loading System is an automated pneumatic conveying system designed specifically for milk powder production. It utilizes negative pressure generated by a vacuum pump to safely and safely transfer milk powder from bulk bags or containers to a mixer or storage silo through a sealed pipe.

Voltage: 380V / Customizable

Application: Product Conveying

Frame Material: 304, 316 Stainless Steel/Carbon Steel

Capacity: 10 kg - 10 tons/hour

Length: Customizable, 1-100 meters

Filter: Stainless Steel Filter Element

Conveyed Materials: Whey Powder, Lactose, Nutritional Enhancers, Whey Powder, Lactose Powder, Whey Protein Powder

What is a Milk Powder Vacuum Loading System?

Milk Powder Vacuum Loading System is a closed, automated conveying system designed for milk powder production. Its core technology utilizes negative pressure to ensure the clean transfer of milk powder and raw materials. All parts that come into contact with milk powder are made of stainless steel, with mirror-polished interiors. Using an oil-free vacuum pump to generate a stable negative pressure, the system conveys whey powder, lactose, and finished milk powder from bags and silos to mixers, packaging machines, screeners, and other equipment. The entire process is sealed to prevent dust and moisture absorption, preventing milk powder from clumping and microbial contamination. Furthermore, we support custom production and can tailor a vacuum loader to your production needs and on-site requirements.

What are the advantages of the Milk Powder Vacuum Loading System?

The Milk Powder Vacuum Loading System offers multiple core advantages in milk powder conveying. These advantages not only address the pain points of traditional conveying methods but also meet the modern food industry's demands for safety, speed, and intelligence.

Gentle Conveying and Anti-Breakage: Vacuum conveying with negative pressure ensures a moderate conveying speed, preventing particle breakage caused by high-speed collisions. Compared to mechanical conveying methods, this reduces the proportion of fine powder in milk powder, maintaining product solubility and taste consistency.

Flexible Feeding for Multiple Stations: A diverter valve design allows a single unit to simultaneously feed multiple stations, reducing equipment footprint and investment costs.

Fast Conveying with Short Cycle Times: The vacuum loader completes a conveying cycle in 10-15 seconds, significantly faster than traditional manual handling or screw conveyors.

Flexible Scalability: The unit supports customized designs for pipe length and number of branches, easily adapting to different production capacity requirements.

Compatible with Various Materials: By adjusting the vacuum level and conveying speed, the unit can handle materials of varying particle sizes and fluidities, such as whole milk powder, skim milk powder, and whey powder, avoiding blockages caused by varying material properties.

Working Principle of the Milk Powder Vacuum Loading System

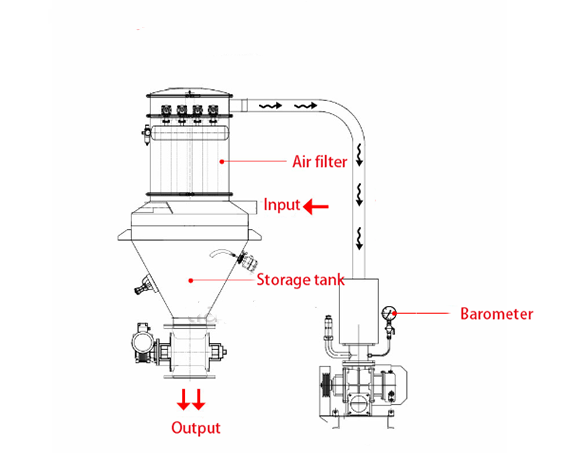

The Milk Powder Vacuum Loading System uses an oil-free vacuum pump to create negative pressure, sucking milk powder into the separation silo. A food-grade filter element intercepts powder and exhausts air, backflushing to remove dust and prevent blockage. Once full, the system shuts down and opens the discharge valve to discharge the powder. This fully sealed process prevents contamination and meets food production requirements.

Suction: Vacuum is created, and the material is drawn into the conveying chamber.

Filtration and Separation: The material and air are separated within the chamber, allowing the material to settle and the air to be discharged through the precision filter.

Discharge: The vacuum is closed, the bottom valve of the chamber is opened, and the material falls by gravity into the receiving equipment.

Cleaning and Preparation: Compressed air automatically backflushes the filter element, cleaning it and preparing for the next cycle.

Milk Powder Vacuum Loading System Technical Parameters

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

What are the application processes of the Milk Powder Vacuum Loading System?

Milk Powder Vacuum Loading Leveraging its core advantages of being airtight, clean, and moisture-resistant, the system is deeply integrated into every key step of milk powder production, ensuring material quality and transportation efficiency from raw material input to finished product delivery.

Raw Material Pretreatment Section: In addition to basic raw material feeding, the vacuum loader can integrate with raw material screening and impurity removal processes during raw material pretreatment, achieving synergistic "transportation pretreatment."

Batching and Premixing Section: In addition to conveying materials to the high-speed mixer according to the formula, the vacuum loader can be customized with a "micro-transfer module" for applications such as infant formula that require the addition of trace nutrients.

Semi-finished Product Transfer Section: Semi-finished product transfer not only covers the transfer of powders between homogenization, sterilization, and drying processes, but also offers customized solutions for key steps after drying. For example, since milk powder particles produced by a spray dryer are prone to moisture absorption, the vacuum loader can be directly connected to the dryer outlet. , quickly conveying semi-finished milk powder to the fluidized bed cooler via a sealed pipeline, reducing the powder's contact time with air and preventing moisture absorption and clumping.

Finished Product Post-Processing: During the post-processing phase before finished product packaging, the vacuum loader can connect to processes such as finished product mixing and metal detection. For example, when multiple batches of finished milk powder need to be homogenized, the loader conveys the different batches of finished product to a double-screw mixer. After mixing, they are then conveyed to a metal detector. Finished products that pass inspection are directly transferred to the packaging machine hopper, achieving a closed-loop "mixing, testing, and packaging" process.

Recycled Material Processing: The small amount of recycled material generated during milk powder production is prone to contamination and waste due to traditional manual recycling. The vacuum loader can handle this through a "dedicated recycling conveying system": equipped with independent small hoppers and food-grade piping, the recycled material is vacuum-pressure-drawn from the residual points of each piece of equipment and conveyed to a dedicated recycling mixing tank.

Milk Powder Vacuum Loading System Components

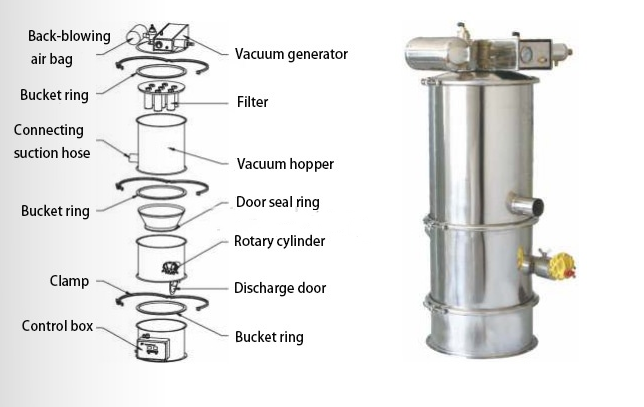

The Milk Powder Vacuum Loading System primarily consists of a vacuum pump, polishing silo, filter, discharge valve, and control system. Its fully enclosed design eliminates contamination and enables automated, sterile conveying from feeding to mixing.

Vacuum Pump: Commonly used are Roots blowers or vacuum generators, suitable for short-distance, gentle conveying. For food applications like milk powder, its material and sealing properties must meet hygienic requirements.

Vacuum Buffer Tank: This stabilizes the system's vacuum level and prevents powder from being drawn into the vacuum pump, providing protection.

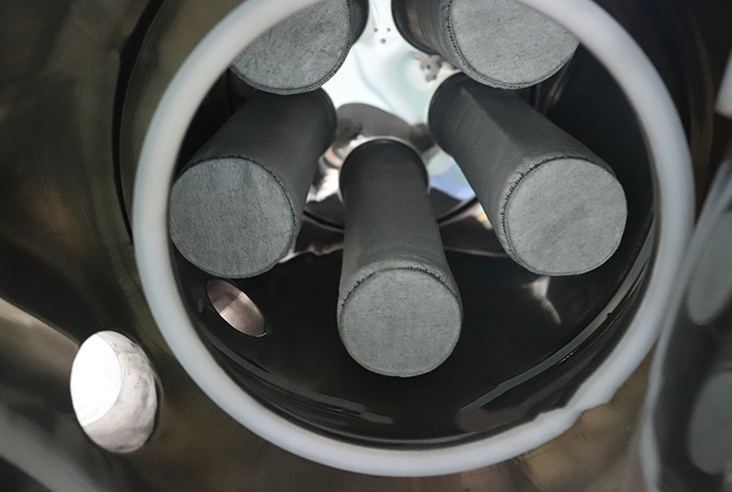

Filtration System: The filtration system is central to efficient gas-to-material separation, ensuring that powder particles are trapped and clean air is discharged. The core component, the filter element, must be made of food-grade material, with coated polyester filter media or stainless steel sintered filter elements being the most common, meeting hygienic requirements.

Discharge Valve: The discharge valve is installed at the bottom of the intake silo. Its core function is to maintain a sealed silo during the conveying phase and to quickly open during the discharge phase to accurately discharge the powder into downstream equipment.

Why is a vacuum loader essential for milk powder production?

Milk Powder Production Must Use a Vacuum Loader The vacuum loading system, with its fully enclosed, automated conveying system, completely eliminates human and environmental contamination, significantly increasing production capacity while preserving nutrients and fundamentally eliminating dust safety hazards.

Eliminating Contamination: The fully enclosed conveying system completely isolates the risk of product contamination from human bodies and ambient air, effectively preventing the intrusion of foreign matter.

Guaranteed Product Quality: It eliminates dust and cross-contamination caused by manual feeding, ensuring product formula accuracy and batch consistency.

Improving Production Efficiency: It achieves continuous, automated operation with a conveying capacity of up to several tons per hour, significantly reducing reliance on manual labor, labor intensity, and production costs.

Safety and Hygiene: It eliminates the risk of dust explosions and protects the health of operators. No dust leakage, creating a clean production environment.

Milk Powder Vacuum Loading System Special Requirements for the System

Compared to other industries, milk powder loaders differ significantly in design and material, with sanitary design being the core requirement.

Material: All parts that come into contact with the product must be made of 316L stainless steel, with surfaces mechanically or electrochemically polished to a mirror-like finish. This eliminates dead corners, makes cleaning easy, and eliminates the breeding of bacteria.

Sanitary Connections: Quick-release clamps are used, rather than bolts, for quick disassembly, inspection, and thorough cleaning.

Filters: Food-grade, hydrophobic membrane filter media must be used to ensure high filtration accuracy, resist product adhesion, and withstand frequent CIP cleaning and high-temperature sterilization.

Cross-contamination Prevention: The design requires no residue, ensuring no cross-contamination when changing product recipes.

Milk Powder Vacuum Loading System Customer Case Studies

As a source manufacturer, we provide milk powder vacuum loading systems to customers across various industries. The system output solution offers improved conveying efficiency compared to previous systems. We provide a perfect solution tailored to the customer's site conditions and production needs, and can be used in conjunction with other equipment to achieve complete conveying.

Smart Upgrade for Dairy Companies: To improve milk powder conveying efficiency and safety, a customized dual-pump parallel vacuum loading system has been developed, with a conveying capacity of 2000 kg/h and a coverage of 20 meters horizontally and 5 meters vertically. The equipment utilizes 316L stainless steel piping, explosion-proof motors, and an integrated PLC control system, reducing dust concentration from 120 mg/m³ to 0.3 mg/m³.

Brand-Friendly Flexible Production: Targeting Multiple Product Categories To meet the needs of shared milk powder production lines, a customized modular vacuum loader was developed. Quick-release clamp piping and removable filters enable 5-minute material changeovers. Frequency conversion control reduces the conveying speed to 6 m/s, minimizing particle breakage. Combined with a CIP (Cleaning in Place) and a diverter valve feed system, the equipment simultaneously serves four packaging lines, reducing cleaning time by 70%.

Factory Environmental Adaptation: To address milk powder clumping and equipment corrosion issues in tropical regions, a Southeast Asian dairy factory customized an anti-caking vacuum loader. This loader utilizes a vibrating screen to break up lumps, an insulation layer to control material temperature, and 316L stainless steel components with Teflon coating for corrosion resistance.

Milk Powder Vacuum Loading System Pricing

As a professional milk powder vacuum loading system manufacturer, we offer highly competitive pricing, with basic models starting as low as $800. Prices fluctuate based on various factors. For materials, 304 stainless steel is affordable. Upgrading to 316L stainless steel offers increased corrosion resistance and suitability for harsh environments, but this will incur a corresponding increase in cost. Adding a CIP cleaning system for easier cleaning and maintenance will also increase the price. Low-volume, basic-configuration equipment can meet the needs of small milk powder plants; high-end models with larger transfer capacities and specialized features are more expensive. Please feel free to contact us; we will provide a cost-effective solution and an accurate quote tailored to your needs.

In the milk powder production process, from the addition of raw materials such as whey powder, lactose, and nutritional supplements to the transportation and packaging of finished milk powder, strict requirements are placed on material cleanliness, contamination prevention, and moisture absorption prevention during material handling. Traditional manual feeding or mechanical conveying can easily lead to dust, microbial contamination, and raw material agglomeration. These factors not only affect milk powder quality and safety, but can also pose health risks to operators due to the spread of dust. Milk Powder Vacuum The Loading System is centered around "fully enclosed negative pressure conveying" and is custom-designed based on the characteristics of milk powder raw materials and finished products, becoming a key piece of equipment connecting all aspects of milk powder production.