Pigment Vacuum Loader

Pigment Vacuum Loader effectively eliminates the dust created by traditional manual loading, trapping micron-sized dust and ensuring emissions meet standards. It is an ideal choice for clean, intelligent upgrades in pigment production and packaging, among other processes.

Dimensions (length * width * height): 220*250*880/customizable

Features: antibacterial, easy to clean

Voltage: 380V, 110V, 220V, 440V, 480V, customizable

Function: material conveying

Machine type: liftable vacuum feeder

Thickness: 3-30 mm

Capacity: 100 kg - 20 tons/hour

Material: PU, rubber, stainless steel

Speed: adjustable, 20 m/min

Hose material: stainless steel, PVC

Applicable Materials: Pigments, milk powder, cement, pharmaceutical powder, PVC powder, pollen, plastic powder, ink powder

What is a Pigment Vacuum Loader?

Pigment Vacuum Loader is an automated device based on pneumatic conveying principles. It uses vacuum pressure to generate a closed airflow, gently and dust-free transferring pigments from raw material containers to mixers, reactors, or packaging equipment. To address the potential for pigments to fly, be purity-sensitive, and be prone to cross-contamination, the device utilizes polished stainless steel, an anti-static and explosion-proof design, and features a residue-free structure and intelligent cleaning system to ensure color consistency.

Our Pigment Vacuum Loader is available in 304 stainless steel, 316L stainless steel, and wear-resistant ceramic linings, meeting the material characteristics of various industries. The device's height, inlet, and outlet locations can be flexibly adjusted to suit the customer's on-site equipment layout. Whether it's connecting to high-level storage silos, low-profile reactors, or adapting to angled feeds at specialized workstations, it can be precisely adapted without modifying existing production lines.

What are the advantages of the Pigment Vacuum Loader?

The pigment vacuum loader features fully enclosed negative pressure conveying. Its corrosion-resistant and contamination-resistant 316L stainless steel/PTFE lining provides high-precision filtration for dust control. Its easy-to-clean design accommodates frequent color changes and precisely controls pigment quantity to minimize waste.

Ensuring pigment quality: Pigment production requires extremely high purity levels. Even the slightest cross-contamination between different pigments can severely degrade product quality. The pigment vacuum loader utilizes a fully enclosed conveying design, with the entire conveying path, from the suction nozzle to the discharge port, sealed within the pipe and silo.

Adapting to complex production processes: The pigment production process is complex, with precise requirements for material conveying volume and timing at every stage, from raw material addition and material transfer during the reaction process to finished product packaging. The pigment vacuum loader can be equipped with an advanced PLC control system and accurately monitor the pigment level in the silo using capacitive or gravimetric level sensors.

Reducing production costs: Pigment powders are fine and easily fly, leading to material waste rates as high as 10%-15% with traditional conveying methods. Pigment vacuum loaders utilize the principle of negative pressure conveying, allowing the material to move smoothly within the pipeline thanks to airflow, reducing adhesion and loss caused by collisions and friction.

Meeting the needs of frequent color changes: Pigment production often requires frequent changes in product color, making equipment cleaning difficult and time-consuming. The pigment vacuum loader features a modular, quick-release design, allowing components such as the hopper and pipeline to be quickly disassembled for easy cleaning.

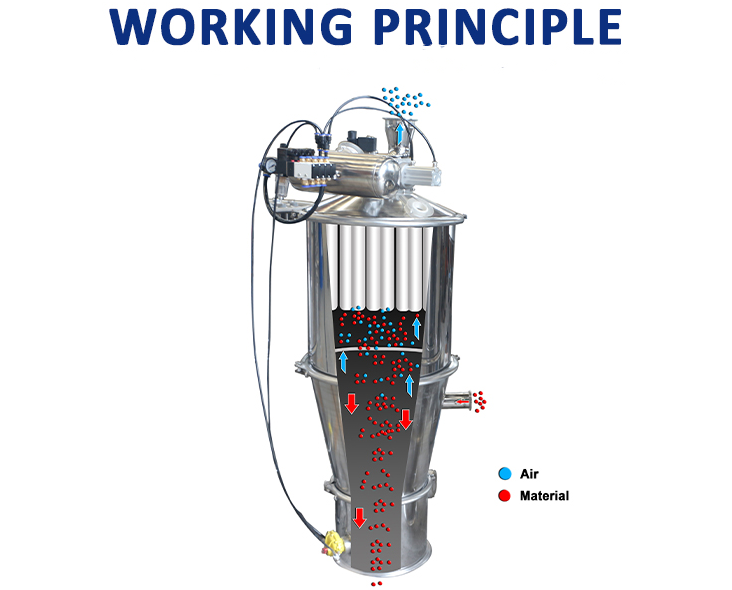

How the Pigment Vacuum Loader Works

The Pigment Vacuum Loader uses a vacuum pump to generate negative pressure, creating airflow within a closed pipeline. This draws pigment particles from the silo into the conveying pipeline. Gas-solid separation occurs through a cyclone separator or cartridge filter, and the material falls into a storage tank. The gas is then discharged through a silencer. For example, one model boasts a vacuum level of -85 kPa and a conveying capacity of 50-5,000 kg/h. It can accommodate horizontal conveying distances of 50 meters and vertical lifting heights of 20 meters.

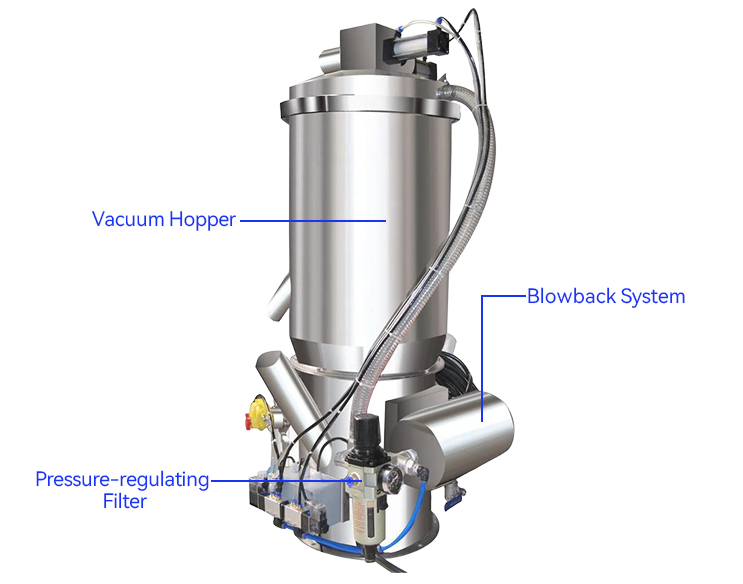

Innovative Pigment Vacuum Loader Structure

The Pigment Vacuum Loader features an innovative quick-release stainless steel silo and lined piping, which is corrosion-resistant and easy to clean. It is equipped with a dual-stage pulse backflush filter to trap fine pigment dust. The inlet angle and outlet height can be flexibly adjusted.

Modular Design: Quick-release clamps connect the piping and hopper, reducing assembly and disassembly time to less than 30 minutes, facilitating equipment cleaning and material switching.

Anti-blocking Technology: To address the clumping problem of damp pigments, a vibrating feeder or auxiliary airflow device is used. For example, titanium dioxide manufacturers have adopted a combination of vibrating screening and vacuum conveying, reducing the clumping rate from 8% to 0.5%.

Explosion-proof Design: In chemical pigment production, equipment must meet explosion-proof standards and utilize explosion-proof motors, electrostatic grounding devices, and a nitrogen protection system to ensure safe production.

Pigment Vacuum Loader Technical Parameters

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

Why is a dedicated Pigment Vacuum Loader necessary for pigment production?

Pigment products are characterized by high added value, high color strength, high airflow, and sensitivity to contamination. Traditional conveying methods present numerous challenges.

Contamination Risk: Particles from metal friction, environmental dust, and other foreign matter can lead to color deviation and reduced purity.

Cross-contamination: Residual material can cause color contamination between batches, resulting in serious quality issues.

Dust Hazard: Pigment dust can easily become airborne, compromising operator safety, and some pigments are flammable.

Material Degradation: Impact or friction can disrupt pigment particle morphology, affecting dispersion and tinting strength.

What are the application scenarios for the Pigment Vacuum Loader?

The Pigment Vacuum Loader is suitable for raw material dosing and post-reaction material transfer in organic and inorganic pigment production; precise pigment feeding in the coatings and inks industry; and material transport in plastic coloring and artist pigment processing, adapting to diverse needs.

Automatic Raw Material Dosing: In the front-end process of pigment production, the vacuum loader is used to automatically weigh and enclosedly dosing raw materials such as titanium dioxide and iron oxide. The system, controlled by a PLC, precisely meters and directly delivers the powder to the synthesis reactor, completely eliminating human contact.

Dust-Free Packaging of Finished Products: In the finished pigment processing stage, the equipment provides fully enclosed transport of dried pigment granules from the dryer to the packaging machine silo. Organic pigment manufacturers have adopted this solution, completely eliminating dust leakage issues in the packaging area.

Flexible Production Switching: To meet the needs of small-batch production of multiple varieties, the equipment utilizes a quick-release filter element and an integrated CIP cleaning system, enabling rapid switching between different pigment production colors.

What are the humidity requirements for pigments during transportation using a Pigment Vacuum Loader?

The humidity requirement for pigments during transportation using a Pigment Vacuum Loader is typically 35%-45% RH (the specific value depends on the material properties), and the moisture content of the pigment itself must be controlled within a reasonable range to avoid decreased fluidity and equipment failure. The impact of humidity on pigment transportation should be analyzed from the following perspectives.

Decreased fluidity: When the moisture content of pigment exceeds 1%, a layer of adhesion easily forms between particles, resulting in poor fluidity.

Increased risk of equipment failure: Wet pigments tend to adhere to the filter surface, reducing filtration efficiency. Experiments show that when the moisture content of pigments increases from 0.5% to 1.5%, the frequency of filter clogging increases by 40%, requiring frequent downtime for cleaning and impacting production continuity.

Dust generation exacerbates: High-humidity pigments are prone to static electricity generated by friction during conveying. However, if the humidity is too high, the static voltage decreases, but material can adhere to the inner wall of the pipe, causing secondary dust generation during subsequent drying.

Piggy Vacuum Loader Customer Case Studies

We use the Pigment Vacuum Loader to provide clients in various industries with perfect vacuum conveying solutions. We offer different types of conveying solutions tailored to specific customer scenarios, enabling us to create the perfect production line for each client.

Pharmaceutical Company:Manually transporting raw powder to a three-dimensional mixer presented significant challenges, including severe dust pollution and low mixing efficiency. After introducing the vacuum loader, the equipment utilizes high-efficiency filters and anti-static piping for sealed conveying, creating a fully automated "loading-mixing" process. Ultimately, single-batch mixing time was reduced from 45 minutes to 27 minutes, a 40% increase in efficiency.

Milk Powder Company:The original screw conveyor fed a four-station packaging machine, which often stalled due to uneven feeding. After adopting the vacuum loader, with its inverter speed control and weighing module for real-time level monitoring, the packaging machine stall rate was reduced from 15% to 0.5%, and the single-bag weight error rate was reduced from 0.8% to 0.3%, exceeding industry standards.

New materials companies:Manually transporting raw materials to air jet mills and vibrating screens results in material waste and dust pollution. A vacuum loader was introduced to create a closed-loop "conveying-crushing-screening" system. This system, combined with wear-resistant ceramic piping and a pulse backflush filter, is suitable for conveying ultrafine powders.

Pigment Vacuum Loader Supplier

We are a leading manufacturer specializing in the R&D, production, and service of pigment vacuum loaders, specializing in providing efficient conveying solutions for the pharmaceutical, food, chemical, and new materials industries. The core team has years of industry experience and can precisely meet customers' non-standard needs. From materials and production capacity to functionality, the equipment can be customized to suit the diverse characteristics of pigments, milk powder, cement, pharmaceutical powders, and more. The equipment undergoes rigorous quality testing and offers a full service process from solution design to commissioning and after-sales maintenance.

The Pigment Vacuum Loader is more than just a conveying device; it serves as a bridge connecting all stages of pigment production. Through technological innovation and scenario-based applications, it helps the pigment industry achieve the transition from "manufacturing" to "smart manufacturing," providing more stable raw material support for downstream industries such as global coatings, inks, and plastics.