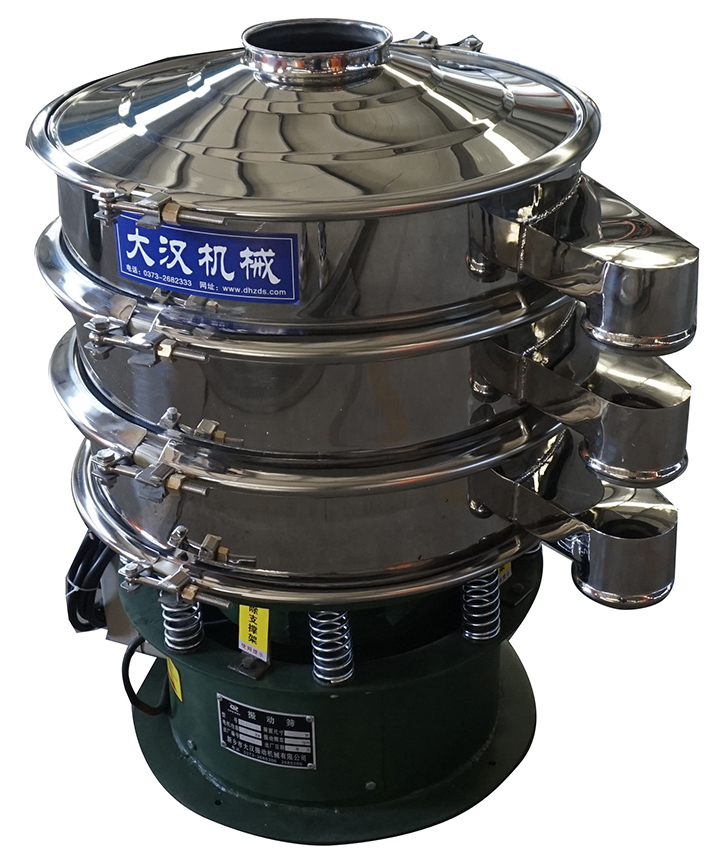

Tumbler Screening Machine

The price range of Tumbler Screening Machine is $800to $3600/Set,which is a practical equipment to solve the problem of screening powdery and granular materials.

layer:1-5 layers

Feed rate: 1kg/h - 50t/h

Mesh Size:20 microns - 20 mm

Acceleration:1,3-1,8 g

Material:carbon steel, stainless steel and special steel

What is a Tumbler Screening Machine?

The Tumbler Screening Machine is a device that simulates manual screening action. It combines circular motion and parabolic motion to separate, grade and remove dust from powdery and granular products. The screening accuracy can reach more than 90%-95%, and it is suitable for a wide range of meshes from 10-600 meshes. It can handle various materials from coarse particles to fine powders, especially suitable for handling complex materials such as easy to agglomerate, fragile, and irregular.

When choosing a Tumbler Screening Machine, it is necessary to judge based on the specific mesh and characteristics of the material. For example, for processing medium-coarse particles (quartz sand, fertilizer) of 10-100 mesh, it is suitable to use a circular Tumbler Screening Machine, which can be adapted to large-scale production; for ultra-fine powders (pharmaceutical powders, pigments) of 200-600 meshes, it is suitable to use an ultrasonic Tumbler Screening Machine, which can ensure screening accuracy; at the same time, the number of screen layers (1-5 layers) should be determined according to the mesh span to ensure accurate grading of each layer and improve screening efficiency.

What are the categories of Tumbler Screening Machines?

Among Tumbler Screening Machines, Circular Tumbler Screening Machines and Ultrasonic Tumbler Screening Machines are two common types, and the two have obvious differences in structure and applicable materials.

Circular Tumbler Screening Machine: It adopts a circular structure, with a circular screen drum as the core, and achieves screening through rotation and tilt angle. It is suitable for processing large-volume granular materials, such as quartz sand, fertilizer particles, construction waste particles, etc., and can achieve multi-layer classification, which is suitable for coarse or medium screening needs in large-scale production.

Ultrasonic Tumbler Screening Machine: Equipped with an ultrasonic system, it uses high-frequency sound waves to break material agglomeration. It is suitable for processing ultra-fine and easy-to-stick powder materials, such as flour, pharmaceutical powder, dye powder, etc. It can effectively break material agglomeration and avoid screen blockage, especially suitable for fine processing scenarios with high screening accuracy requirements.

What are the advantages of Tumbler Screening Machines?

The core advantages of the Tumbler Screening Machine include: the use of flexible screening methods, through low-amplitude swinging motion to reduce the collision and friction between materials, can reduce the loss rate of fragile materials (such as baked crisps, Chinese herbal medicine pieces); the multi-layer screen can independently adjust the inclination angle, can simultaneously complete 2-5 kinds of particle size classification, and adapt to the production needs of multiple specifications; the built-in brush and elastic ball cleaning components can clean the screen holes in real time during the screening process to prevent the screen from being blocked; the quick-release screen structure is combined with the buckle connection, and the screen can be replaced by one person in 5 minutes, which greatly shortens the maintenance downtime and is especially suitable for multi-batch small-batch production scenarios.

Tumbler Screen Technical Parameters

| Particle feed size: | 1 micron up to 20 mm | ||||||

| Feed rates: | 1kg/h – 50 ton/h | ||||||

| Bulk densities: | 20 – 10000 grams/liter | ||||||

| Mesh openings: | 20 microns to 20 mm | ||||||

| Screens usable: | 304, 316L, or 430 stainless steels or plastic wire mesh fabric, perforated plates | ||||||

| No. of screen decks: | 1 – 6 per machine | ||||||

| Anti-blinding systems: | – Rubber balls | ||||||

| – Rotating roller brush arms | |||||||

| – Rotating air-jet nozzle arms | |||||||

| – Ultrasonic | |||||||

| – Combinations | |||||||

| Speed range: | 180-280 min-1 | ||||||

| Screen movement: | Three-dimensional, set to product | ||||||

| Amplitude: | 40-80 mm horizontally and 5-40 mm vertically | ||||||

| Acceleration: | 1,3-1,8 g | ||||||

| Model sizes/ca. Ø: | 600 | 1000 | 1200 | 1600 | 2000 | 2400 | 2600 |

| Screening surface (m²): | 0.292 | 0.785 | 1.13 | 1.83 | 2.63 | 4.52 | 5.31 |

| Motor power (kW): | 0.25 | 1.5 | 2.2 | 2.2 | 4 | 5.5 | 5.5/7.5 |

| Materials: | Carbon steel, Stainless and Special steels | ||||||

| Surfaces: | Painted, brushed or ground, mirror or electro polished, and ViwateQ options for Food and Pharmaceutical products with a surface roughness of < 0.4 microns (GMP, FDA compliant). | ||||||

What is the working principle of the Tumbler Screening Machine?

The working principle of the Tumbler Screening Machine is to drive the screen body to perform a composite swing vibration through the drive device, combining the left and right swing centered on the horizontal axis with the slight vibration in the vertical direction, so that the material enters the screen frame to form a spiral motion trajectory. In this dynamic process, the material is constantly turned over and evenly distributed on the screen surface. Particles smaller than the screen hole are penetrated by the dual effects of gravity and vibration and fall into the corresponding level of the aggregate trough; particles larger than the screen hole are gradually pushed along the inclination direction of the screen surface and finally discharged from the end outlet. The hierarchical screen design realizes the precise classification of materials of different particle sizes. The whole process can maintain a stable separation efficiency without manual intervention.

Where can the Tumbler Screening Machine be used?

The application range of the Tumbler Screening Machine is very wide. For example, in food processing, it can process oatmeal (separating broken particles and complete particles) and cocoa beans (grading fruits of different maturity); in the chemical industry, it is used for resin particles (screening raw materials with uniform particle size) and carbon black powder (removing agglomerates); in the pharmaceutical industry, it is suitable for Chinese herbal medicine pieces (distinguishing slices of different specifications) and probiotic powder (anti-caking screening); in the mining industry, it can classify feldspar ore (separating different particles) and talcum powder (ultra-fine classification); in building materials production, it is used for ceramsite (grading by density), etc. It is especially suitable for processing materials with irregular shapes or that need to maintain integrity.

The Tumbler Screening Machine is a practical device that solves the problem of screening powdery and granular materials. It adapts to different material characteristics through rotation and vibration. The circular Tumbler Screening Machine is suitable for medium and coarse particles and large-scale production; the ultrasonic Tumbler Screening Machine breaks the agglomeration of ultra fine powders and improves precision. Flexible screening reduces the loss of fragile materials, multi-layer screens are graded synchronously, brush cleaning saves maintenance, and quick-detachable screens can be replaced quickly. It is suitable for food sorting, chemical grading, pharmaceutical powder screening, mining processing and other fields. It is an ideal choice for balancing efficiency and quality, and provides stable support for material grading in various industries.