Powder Sieve Machine

Powder Sieve Machine is generally priced between $800.00 and $5,000.00 per set.. There are various models available, usually classified by screen mesh (such as 20-200 mesh, 200-500 mesh, 500-800 mesh) and processing capacity.

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3000kg/h

Layer(s): 1-5layers

Material:Stainless steel 304,316L,or Carbon Steel

Model: Ø 400- Ø 2000 mm

What is a Powder Sieve Machine?

A Powder Sieve Machine is a mechanical device used for particle size classification and impurity separation of powdered materials through sieving screens. Its core function is to utilize power sources like vibration or ultrasonic waves to stratify powder particles of different sizes by allowing them to pass through screen apertures. Widely applied in industries such as chemical, food, pharmaceutical, and electronics, it essentially acts like a "weight-based sorter" for powders, directing coarse and fine particles to their respective positions.

What are the Common Types of Powder Sieve Machines?

Vibro Sifter:Consisting of a vibration motor, screen box, and multi-layer screens, it generates three-dimensional vibration driven by the motor. Its adjustable vibration frequency and angle suit different materials. The multi-layer screen design enables simultaneous production of multiple particle sizes, and screens are easy to replace. Ideal for medium-fineness powders (50-500 mesh), it's commonly used in chemical raw materials and food processing.

Ultrasonic Vibrating Screen:This type integrates an ultrasonic generator onto a standard vibro sifter, superimposing high-frequency sound waves onto the screen surface. This configuration effectively solves issues of fine powder agglomeration (above 300 mesh) and screen blinding, reduces electrostatic adhesion, improves sieving efficiency, and extends screen life by 30%-50%. Widely applied in industries demanding high-precision sieving, such as pharmaceuticals and electronics.

Direct Discharge Sifter:Featuring a single-layer screen design, materials are fed directly through the inlet, sieved, and discharged. Compact and easy to install, it suits space-limited production lines. It ensures residue-free sieving for easy cleaning and material changeover, and offers stable processing capacity. Ideal for preliminary sieving of materials with uniform particle distribution, it plays a vital role in ceramics, metallurgy, and building materials industries.

What are the advantages of Powder Sieve Machines?

Powder Sieve Machines offer multiple advantages that make them indispensable in powder processing,these advantages collectively make Powder Sieve Machines a reliable choice for improving production quality and efficiency.

High screening precision: They can accurately classify particles within a wide mesh range (20-800 mesh). For example, Ultrasonic Vibrating Screens can handle fine powders above 300 mesh with minimal error, ensuring consistent particle size distribution.

Excellent efficiency: Vibro Sifters with multi-layer screens can process multiple particle sizes simultaneously, reducing production time by 30%-40% compared to single-layer screening.

Strong adaptability: By adjusting the vibration frequency (30-60Hz) and amplitude (1-5mm), they can handle various powder properties, from dry free-flowing powders to slightly viscous materials.

Durability and cost-effectiveness: Constructed with high-quality materials like SUS316L stainless steel, their service life reaches 8-10 years. Features such as easy screen replacement and low energy consumption minimize long-term maintenance costs.

Enhanced operational safety: Equipped with overload protection and anti-static designs, they reduce risks of equipment damage and dust-related hazards, complying with industry safety standards in food, pharmaceutical, and chemical sectors.

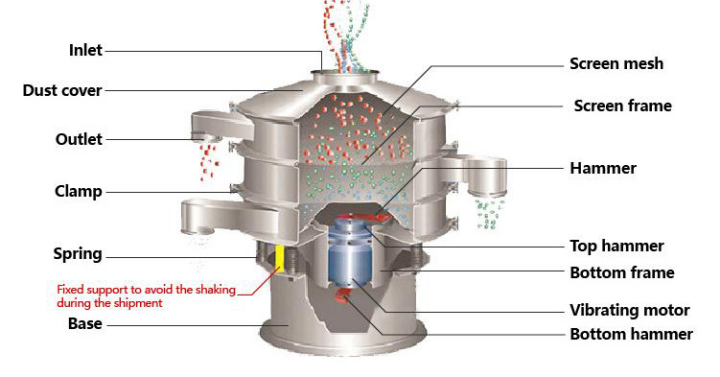

How Does a Powder Sieve Machine Work?

Although power sources vary among different sieve machines, the core workflow consistently involves material feeding, sieving motion, classification/separation, and multi-stage processing.Material Feeding: Powder enters the screen body via the feed inlet, spreading evenly onto the screen mesh.

Sieving Motion: The screen mesh generates vibration/ultrasonic waves/tilting motion under power, propelling particle movement.

Classification & Separation: Fine particles meeting the screen aperture size pass through to the lower layer, while coarse particles travel along the screen surface and discharge from the outlet.

Multi-Stage Processing:Machines with multi-layer screens achieve simultaneous "coarse-medium-fine" three-stage sieving, directly outputting different size specifications.

Technical parameters of powder sieving machine

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Where are Powder Sieve Machines Applied?

Powder sieve machines are widely applied across multiple industries including chemical, food, pharmaceuticals, and electronics, playing crucial roles in processing various materials.Chemical Industry: PVC resin powder classification, rubber additive impurity removal, pigment powder fineness control.

Food Industry: Milk powder impurity screening, spice particle size classification (e.g., chili powder, pepper powder), starch dewatering sieving.

Pharmaceutical Industry: Tablet raw material sieving (ensuring tablet uniformity), Chinese medicine extract powder impurity removal, capsule filling material particle size control.

Electronics Industry: Mobile battery cathode/anode material sieving (a key step affecting battery performance), circuit board solder powder classification.

Other Fields: Building material powders (e.g., putty powder, mortar raw materials), metallurgical powders (e.g., iron powder, aluminum powder purification), new energy materials (e.g., graphene, silicon powder sieving).

What solutions can Powder Sieve Machines provide?

Powder Sieve Machines can address a range of challenges in powder processing. For the problem of fine powder agglomeration and screen blinding, especially with powders above 300 mesh, Ultrasonic Vibrating Screens are effective. Their high-frequency sound waves break up agglomerates, reducing screen blinding by over 60% and improving sieving efficiency by 30%-50%. For scenarios requiring multi-stage classification of medium-fineness powders (50-500 mesh), Vibro Sifters with multi-layer screens are a good solution, enabling simultaneous production of multiple particle sizes in one pass, saving time and labor. In space-constrained production lines, Direct Discharge Sifters, with their compact design, can be easily installed, ensuring efficient preliminary sieving without taking up much space. They also facilitate quick cleaning and material changeover, reducing downtime.

Our factory's Powder Sieve Machines are highly efficient and reliable. They can handle powder sieving from 20 mesh to 800 mesh, with a sieving efficiency of over 95% to ensure precise classification of particles. The Vibro Sifters have an adjustable vibration frequency of 30-60Hz and amplitude of 1-5mm, adapting to different powder properties. The Ultrasonic Vibrating Screens reduce screen blinding by more than 70% for fine powders above 300 mesh and extend screen life by 30%-50%. Made of high-quality SUS316L stainless steel, the equipment has a service life of 8-10 years, minimizing maintenance costs. We offer customized services, such as adjusting screen mesh sizes, modifying machine dimensions, and adding special anti-corrosion coatings, to meet specific production needs of different industries.