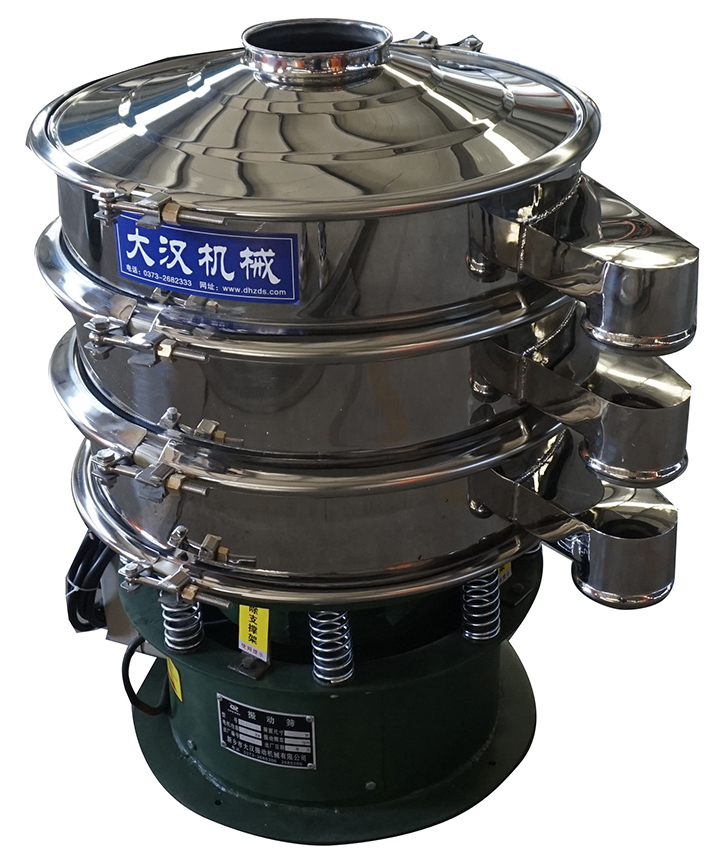

Industrial Sieve Machine

The price of industrial sieve machines is usually between $600 to $5,000/Set. There are many models to choose from, which are generally classified by type (such as vibration screens, linear vibration screens) and processing volume to meet the needs of different production scenarios.

Diameter:400~2000m

Screen Mesh:2-500 Mesh

Capacity:100Kg-10Tons/hour

layer:1-5 layers

Noise Level: less than 80dB

Material:Carbon Steel, Stainless Steel 304/316L

What is an industrial sieve machine?

In the production processes of industries such as mining, building materials, and chemical engineering, Industrial Sieve Machine is a key equipment for material classification and impurity removal, directly affecting the efficiency of subsequent processing and product quality. They can accurately separate block and granular materials by particle size, remove unqualified impurities, provide standard-compliant raw materials for production lines, and reduce wear and energy consumption of downstream equipment.

Different production scenarios have significantly different requirements for screening machines: screening after coarse crushing in mines requires equipment to resist high-intensity impact, while fine screening in the food industry demands equipment to meet hygiene standards. Choosing the right industrial sieve machine can increase material processing capacity by more than 30%, reduce the rework rate caused by unqualified materials, and stabilize the production process.

How to select the type of the industrial sieve machine?

Selecting the right type of industrial sieve machine depends on material properties, screening requirements (such as particle size grading and processing capacity), and application scenarios. Matching the sieve type to specific needs ensures efficient and accurate separation results.

According to the material

Check material characteristics: For materials with corrosive components, choose 304 stainless steel to avoid rust; for dry and non-corrosive materials, ordinary carbon steel is optional for lower cost.

Consider environmental conditions: Prioritize stainless steel in humid or high-moisture environments; carbon steel is more economical in dry and normal temperature settings. For food/pharmaceutical contact, food-grade stainless steel is required.

Evaluate wear resistance needs: For materials with sharp particles or high hardness (e.g., ores), select high manganese steel for impact resistance and wear resistance; ordinary steel is suitable for lightweight materials.

Pay attention to hygiene standards: Stainless steel is a must in the pharmaceutical and food industries for easy cleaning and no residue; in general industrial scenarios with low hygiene requirements, carbon steel can be flexibly chosen.

According to the products

Rotary vibrating screen: With a multi-layer screen design, it can achieve simultaneous separation of 3-6 particle size grades, suitable for fine analysis of multiple particle size ranges in sand and gravel tests. For example, in the gradation detection of concrete sand, it can obtain sample data of multiple particle size segments at one time.

Linear vibrating screen: It has stable processing capacity and is suitable for the pretreatment stage of bulk sand and gravel samples. For instance, in the large-scale particle size screening of sand for road construction, it can quickly separate basic samples that meet the test requirements.

Swing screen: It features small operating amplitude and low noise, with excellent screening effect on sand and gravel samples containing viscous components like clay. It avoids screen blockage that may affect the test progress, and is especially suitable for the separation test of soil-sand mixed samples.

Ultrasonic vibrating screen: Equipped with a high-frequency ultrasonic system, it can effectively break up agglomeration of fine sand and gravel (such as quartz sand powder), ensuring accurate screening of ultra-fine particle sizes below 0.075mm, which meets the requirements of high-precision material tests.

What are the core advantages of industrial sieve machine?

The core advantages of industrial sieve machine directly determine their value in production lines, affecting operational efficiency, cost control, and product quality stability. These strengths help enterprises optimize screening processes and gain competitive edges in diverse industrial scenarios.

High automation level: Enables continuous unmanned operation, reducing manual operation costs.

Stable screening precision: With an error margin controlled within 2%, it ensures consistent product quality and lowers customer complaint rates.

Modular structure: Facilitates easy replacement of wear parts, reducing downtime for maintenance.

Low energy consumption: 25% more energy-efficient than traditional equipment, saving significant electricity costs in long-term use.

Strong adaptability: A single device meets screening needs at different production stages, improving equipment utilization and making the screening process more efficient and economical.

Technical Parameters of Industrial Sieve Machine

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

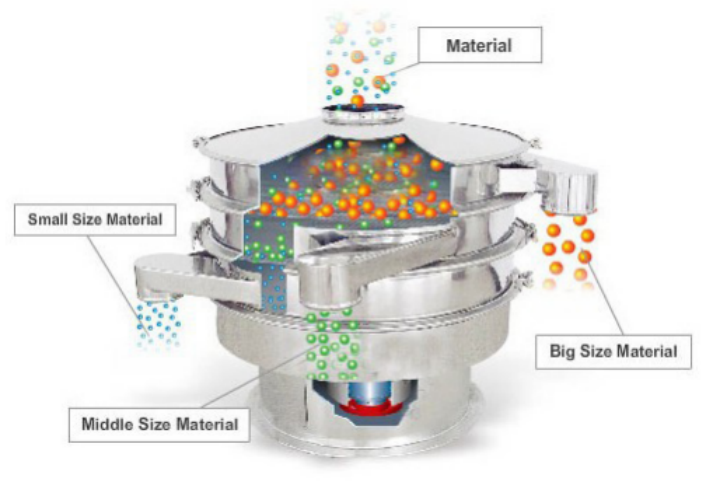

What is the core working principle of industrial sieve machines?

Regardless of the type, the core principle of industrial sieve machines is "separation based on particle size differences". This process relies on mechanical forces or airflow to create relative motion between materials and the sieve surface, allowing particles smaller than the sieve holes to pass through while retaining larger ones, with specific implementation methods varying by device.Vibrating devices: The inertial force generated by vibrations disperses and bounces materials on the sieve surface, accelerating the passage of fine particles through the sieve holes, while coarse particles are gradually discharged due to differences in their movement trajectories.

Rotary devices: The rotation of the drum or disc makes materials tumble. Smaller particles pass through the sieve mesh under the action of gravity and centrifugal force, while larger particles are discharged at the end of the drum as it rotates.

Airflow devices: High - speed airflow blows materials towards the sieve mesh, and at the same time, negative pressure adsorbs fine particles. Separation is achieved through the combined effect of air resistance and sieve hole size.

Where can industrial sieve machines be applied?

With their diverse functions, industrial sieve machines play a crucial role in multiple industries. They are widely used in the food, mining, pharmaceutical, chemical, and construction sectors. These industries rely on such machines to handle material processing tasks tailored to their specific operational contexts.

.

Food industry: Used for removing impurities from flour, grading sugar grains, etc. The equipment materials must meet food - grade standards (such as 304 stainless steel), be easy to clean, and have no sanitary dead corners to ensure that materials are not contaminated.

Mining industry: Suitable for screening high - hardness and high - abrasion materials such as ores and gravels. Sieve machines are required to have a high - strength body and wear - resistant sieve meshes, and be able to adapt to harsh outdoor or dusty environments.

Pharmaceutical industry: Indispensable in links such as the purification of active pharmaceutical ingredients and the grading of excipients. Strictly adhering to GMP standards, the equipment needs to have a design without dead corners, be operable under sterile conditions, and achieve a screening accuracy controlled at the micron level.

Chemical industry: Commonly used for handling corrosive materials such as acid - base solutions and chemical powders. The equipment must use anti - corrosion materials (such as polytetrafluoroethylene) and, in flammable and explosive scenarios, also have explosion - proof functions.

Construction industry: Mainly applied to the grading of sand and gravel and the screening of concrete aggregates. It emphasizes high throughput and rough screening. Although the accuracy requirement is relatively low, it needs to be able to withstand continuous high - intensity operation.

What are the solutions to common industrial sieve machine sieve problems?

In industrial screening processes, production capacity, precision, and blockage are the three core problems that trouble enterprises. Mastering targeted solutions can effectively improve production efficiency and product quality.

Insufficient production capacity: If the processing capacity of existing equipment cannot keep up with the rhythm of the production line, it can be upgraded to a double-screen linear vibrating screen. The production capacity can be increased by 50% by expanding the screening area.

Low screening precision: Material mixing leads to unqualified products. It is recommended to switch to an ultrasonic vibrating screen. High-frequency vibration can break up fine powder agglomeration, and the precision can be improved to over 98%.

Easy blockage of equipment: When processing viscous materials (such as clay), choose a swing screen with an anti-blocking device. The slow swinging reduces material adhesion and lowers the cleaning frequency.

How to choose a manufacturer of industrial sieve machines?

Our equipment's screening range covers 10 to 500 mesh. Among them, the ultrasonic vibrating screen can stably handle 500-mesh ultrafine powder with a screening accuracy of 99%, solving the problem of insufficient accuracy caused by fine powder agglomeration. The linear vibrating screen, in 10-100 mesh coarse screening scenarios, can reach an hourly capacity of 80 tons, easily addressing insufficient productivity. The swing screen, equipped with anti-clogging screen mesh, reduces the clogging rate by over 70% when handling 20-200 mesh sticky materials.The equipment adopts wear-resistant manganese steel screen mesh, whose service life is 3 times longer than that of ordinary screen meshes. It also supports customization of screen mesh size, equipment dimensions, and vibration parameters according to material characteristics. Whether for high-hardness ores or easily sticky materials, it can match exclusive screening solutions to effectively solve practical problems in production.