Electric Automatic Sieve Shaker

The price range of Electric Automatic Sieve Shaker is $20to $3600/Set, which is suitable for materials such as minerals, food, and medicine to meet testing and production needs.

layer:1-6 layers

Mesh Size:2-400 Mesh

Capcity:2kg~ 20 kg/h

Diameter:200mm

Material:Stainless Steel 304/316L,Plastic

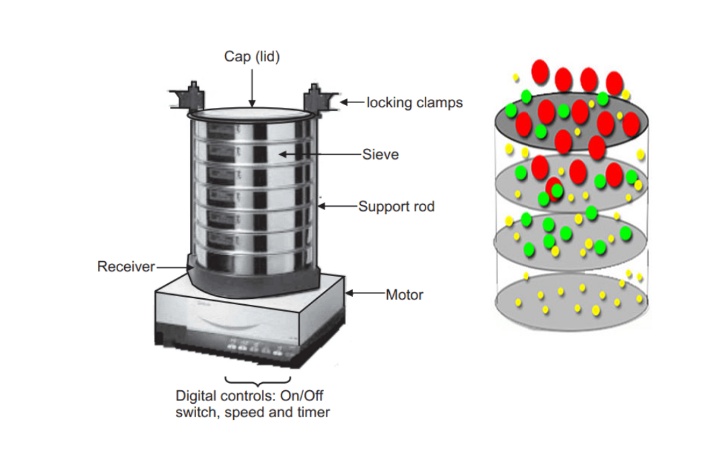

What is an electric automatic sieve shaker?

Electric Automatic Sieve Shaker is an automatic screening equipment commonly used in laboratories and small-scale production. It realizes the vibration of the sieve body through motor drive, and completes the material particle size classification and impurity separation with screens of different specifications, replacing manual screening to reduce errors and improve the efficiency and accuracy of material analysis in tests and production.

The material of Electric Automatic Sieve Shaker should be selected according to the characteristics of the material: stainless steel is selected for acid-base or high hardness, plastic or 304 stainless steel is selected for food and medicine, and the material that is easy to agglomerate must be equipped with ultrasonic function; finally, combined with the purpose of screening, the test analysis needs to focus on accuracy (such as top impact screen), and batch processing needs to take into account efficiency (such as slap screen) to ensure that the equipment is fully matched with the material characteristics and usage scenarios.

What are the categories of electric automatic sieve shakers?

Electric automatic sieve shakers mainly include slap screens, top impact screens, ordinary screens, and ultrasonic test screens, and the materials are mostly stainless steel and plastic.

Ordinary test screen: mainly used for screening loose materials with medium and coarse particle size (>200 mesh). For cement fineness testing and soil particle analysis, the horizontal linear vibration of ordinary sieves can quickly penetrate the material layer, allowing coarse particles (>200 mesh) to pass through the sieve quickly. It is easy to operate and can process 5-10kg of samples per hour, which is much more efficient than manual screening.

Slap screen: specially designed for coarse particles (50-200 mesh) and easy to agglomerate materials. For example, wet-ground ceramic slurry and fertilizer particles that are easy to agglomerate. The horizontal reciprocating slapping action of the slap screen can strongly break the material agglomeration and avoid clogging of the screen.

Top impact screen: suitable for accurate classification of materials with medium hardness and medium particle size (100-500 mesh). Metal powders (such as aluminum powder and iron powder) have large friction between particles and are easy to stack; high-density ore powders (such as iron ore) are easy to accumulate on the screen surface under gravity. The vertical high-frequency vibration of the top impact screen can make the material jump loosely and spread evenly on the screen to avoid material stacking.

Ultrasonic test sieve: suitable for ultra-fine (>500 mesh) or fine powders that are easy to electrostatically adsorb. For example, nano-scale silica and plastic particles, ultrasonic vibration can destroy the van der Waals force and electrostatic adsorption between materials, and cooperate with high-frequency mechanical vibration to allow ultrafine particles to pass through the screen smoothly, with a classification accuracy of up to 5μm, which is suitable for pharmaceutical raw materials, high-end coatings and other scenes with strict particle size requirements.

What are the advantages of electric automatic sieve shakers?

The advantages of Electric Automatic Sieve Shaker are reflected in the precise handling of materials: the body occupies a small area, suitable for desktop operation, adjustable vibration parameters, and support for automatic loading/unloading (reducing manual intervention); the contact part of the test equipment with the material can be made of 304/316L stainless steel, Teflon coating and other materials to avoid metal contamination (suitable for food/medicine) or sticky residue (suitable for slurry/paste); automatic operation avoids particle size analysis deviations caused by manual operation; targeted design of different types of equipment (such as ultrasonic anti-agglomeration and strong power of slapping screen) ensures that all types of materials can be accurately screened, making the test data more reliable and the production raw materials purer.

Electric Automatic Sieve Shaker mesh size

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

What is the working principle of the electric automatic sieve shaker?

The core of the electric automatic screen vibrator is the vibration energy generated by the motor drive, which is converted into different forms such as slapping, top hitting, horizontal vibration or ultrasonic vibration through the transmission structure: the slapping screen and the top hitting screen add impact force in the vertical direction to make the material penetrate the screen; the ordinary test screen vibrates horizontally or obliquely to make the material stratify; the ultrasonic test screen superimposes high-frequency sound waves to break the adsorption force between powders. Finally, the fine particles that pass through the screen fall into the collection device below, and the coarse particles that do not pass through the screen continue to move until they are discharged, realizing classification by particle size. The whole process does not require manual intervention, and the screening efficiency and accuracy are much higher than the traditional method.

What are the applications of electric automatic screen vibrators?

The application of electric automatic sieve shaker covers materials in many fields, such as screening iron ore powder and manganese ore sand in ore testing to analyze their particle size distribution; removing lumps and impurities from cocoa powder and sugar powder in the food industry; screening Chinese medicine powder and pharmaceutical excipients in the pharmaceutical field to ensure uniform particle size; grading catalyst particles and pigment powder in chemical experiments; screening cement clinker and fly ash in building materials testing, and even can be used for fine screening of special materials such as soil samples and metal powders to meet the test and production needs in different scenarios.

As a common equipment in laboratories and small-scale production, Electric Automatic Sieve Shaker not only saves the physical exertion of manual operation through automated vibration design and material adaptation functions, but also avoids the particle size classification deviation caused by uneven force and inaccurate time control in manual screening, fundamentally improving the efficiency and accuracy of screening. Through motor-driven vibration energy, adjustable parameter settings and targeted models, it covers the material screening needs in many fields such as ore, food, medicine, and chemical industry. It uses automation and adaptability to achieve a double breakthrough in screening efficiency and accuracy, becoming a key equipment connecting scientific research data and production quality.