Vibrating Sieve Rapeseed

The price of Vibrating Sieve Rapeseed is $500to $5800/Set,which can effectively remove impurities and keep the particles intact, meeting the needs of rapeseed oil extraction and processing.

layer:1-6 layers

Particle Size: 0.074-10mm

Mesh Size:2-400 Mesh

Noise Level:less than 75dB

Voltage:110V/220V/380V/440V

What is a Vibrating Sieve Rapeseed?

Vibrating Sieve Rapeseed is a screening device used for rapeseed processing. It separates impurities (such as sand, straw, broken grains, etc.) in rapeseed through vibration force, and screens out rapeseed with uniform particles, providing high-quality raw materials for subsequent oil pressing, processing and other links. It can solve the common problems of incomplete impurity cleaning, uneven particle grading, and high rapeseed breakage rate in rapeseed screening, and is a key equipment to improve rapeseed processing efficiency.

If the rapeseed particles are relatively uniform in size, the impurity particles are large, and the output demand is large, you can choose a linear vibrating screen, which can quickly complete the screening of a large amount of rapeseed; if the rapeseed particles vary greatly in size and contain small impurity particles, fine grading is required, you can choose a rotary vibrating screen, which can accurately separate rapeseed of different particles to ensure the screening effect. Only a vibrating screen that matches the material characteristics can reduce energy consumption and loss while ensuring the screening effect.

What types of Vibrating Sieve Rapeseed are there?

Vibrating Sieve Rapeseeds are mainly divided into linear vibrating screens and rotary vibrating screens. Due to differences in design principles, vibration trajectories and functional emphasis, the two correspond to different screening scenarios.

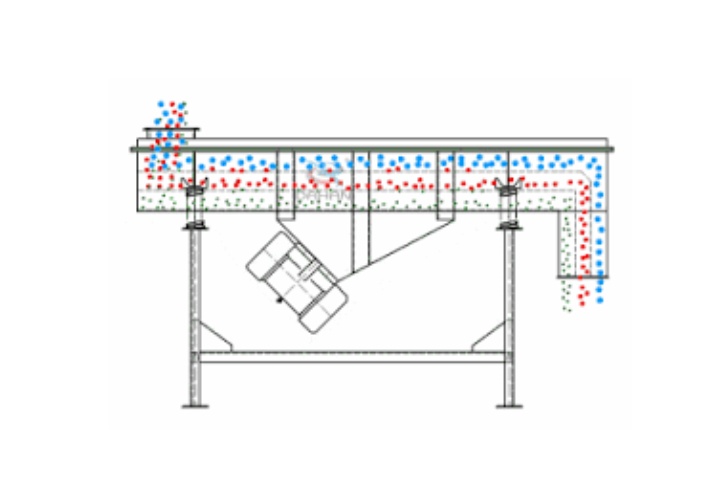

Linear vibrating screen: suitable for large-volume coarse screening scenarios, such as removing large impurities (stones, straw, and long grass) in the initial processing of rapeseed. It is driven by dual vibration motors, and the screen surface moves horizontally and linearly. The processing capacity can reach 5-20 tons/hour, which is suitable for rapeseed with low moisture content and uniform particle size.

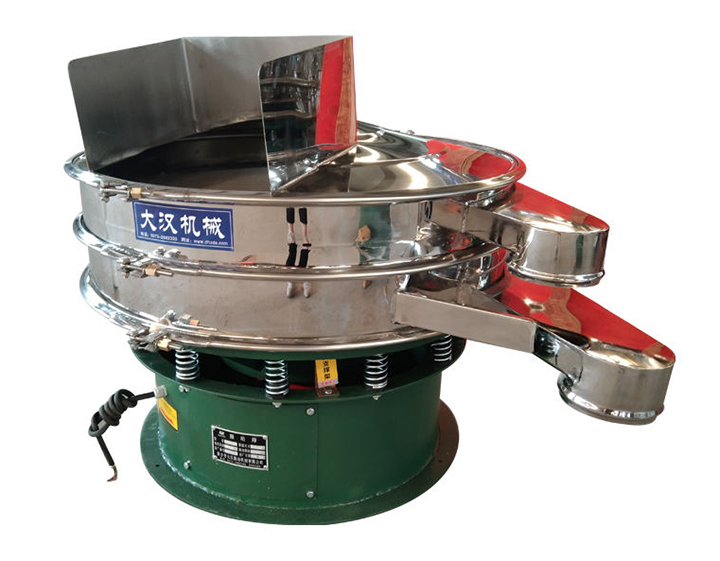

Rotary vibrating screen: suitable for fine screening and multi-level grading, such as removing fine impurities (≤2mm powder) in rapeseed or grading by particle size into 3-5 grades (such as large seeds, medium seeds, and small seeds). It generates a circular vibration trajectory through an eccentric block, and the screen surface shakes at a high frequency. The screening accuracy can reach 50 mesh (about 0.3mm), which is suitable for rapeseed with slightly higher moisture content and easy adhesion.

What are the advantages of Vibrating Sieve Rapeseeds?

Vibrating Sieve Rapeseed can bring many advantages to rapeseed processing. It can improve screening efficiency, reduce manual operations, and reduce labor costs. Its screen adaptability can meet the needs from coarse screening to fine screening, and the screen surface inclination is adjustable, which can flexibly deal with rapeseed with different moisture contents. The part of the equipment that contacts the rapeseed is made of wear-resistant and corrosion-resistant materials to prevent contamination caused by trace moisture or impurities in the rapeseed. The equipment operates stably and has low energy consumption. Long-term use can reduce costs and increase efficiency for enterprises. It has a wide range of application scenarios, such as the initial screening of rapeseed purchasing points, the pre-refining treatment of oil and fat factories, and the rapeseed meal grading of feed factories, all of which can operate stably.

Technical parameters of Vibrating Sieve Rapeseed

Linear vibrating screen

| Model | Layer | Screening Area (mm) | Mesh Size (mesh) | Particle Size (mm) | Capacity (t/h) | Power (kw) | Vibration Direction Angle (°) | Screen Inclination (°) | Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Vibro Sifter

| Model | Diameter (mm) | Feeding Size (mm) | Frequency (RPM) | Layers | Power (kw) | Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

What is the working principle of Vibrating Sieve Rapeseed?

The core of Vibrating Sieve Rapeseed is to obtain kinetic energy of rapeseed on the screen surface through periodic vibration generated by vibration source. When rapeseed enters the screen surface, it keeps rolling and moving under the action of vibration. Particles or impurities smaller than the screen hole are separated through the screen surface, and qualified rapeseed larger than the screen hole is output along the screen surface. Different types of vibrating screens change the movement trajectory of rapeseed on the screen surface by adjusting the vibration direction (linear or rotational) and amplitude: linear vibrating screen allows rapeseed to move at a uniform speed in a directional manner, which is suitable for rapid impurity removal; rotary vibrating screen allows rapeseed to move in three dimensions, achieving more refined classification, thereby accurately meeting different screening needs of rapeseed.

What are the applications of Vibrating Sieve Rapeseed?

The application scenarios of Vibrating Sieve Rapeseed are closely related to rapeseed varieties and processing requirements. Common ones include ordinary rapeseed, double-low rapeseed (low erucic acid and low glucosinolate), black mustard seed, yellow mustard seed, hybrid rapeseed, organic certified rapeseed, etc. Different varieties of rapeseed have different requirements for screening equipment due to different processing goals. In the initial cleaning stage after rapeseed purchase, for coarse seeds such as ordinary rapeseed and hybrid rapeseed mixed with straw and stones, the linear vibrating screen can quickly separate large particles of impurities to ensure the purity of the raw materials for subsequent processing; in the pre-treatment stage before oil extraction, double-low rapeseed or yellow mustard seeds will be further graded by linear vibrating screen to remove small seeds or broken grains that do not meet the specifications; for the processing of fine rapeseed, such as black mustard seeds or organic certified rapeseed, the multi-layer screen of the rotary vibrating screen can accurately divide 3-5 grades according to particle size to meet the refined needs of the high-end market; in the processing of rapeseed meal after oil refining, ordinary rapeseed meal and hybrid rapeseed meal can be graded by particle size through the vibrating screen to improve the utilization rate of by-products.

When using the Vibrating Sieve Rapeseed for impurity removal and grading of rapeseed, the characteristics, impurities and processing requirements of the rapeseed should be considered to select the linear vibrating screen or the rotary vibrating screen. The former is suitable for large-volume coarse screening, and the latter is suitable for fine grading, solving the problems of incomplete impurity cleaning and uneven particle grading. It can cover multiple scenarios such as rapeseed procurement screening, pre-treatment before oil extraction, fine processing, meal grading and feed mixing. In essence, the Vibrating Sieve Rapeseed provides stable and accurate screening support for all aspects of rapeseed processing through precise matching of vibration principle and material characteristics, ultimately helping to improve raw material quality and processing efficiency.