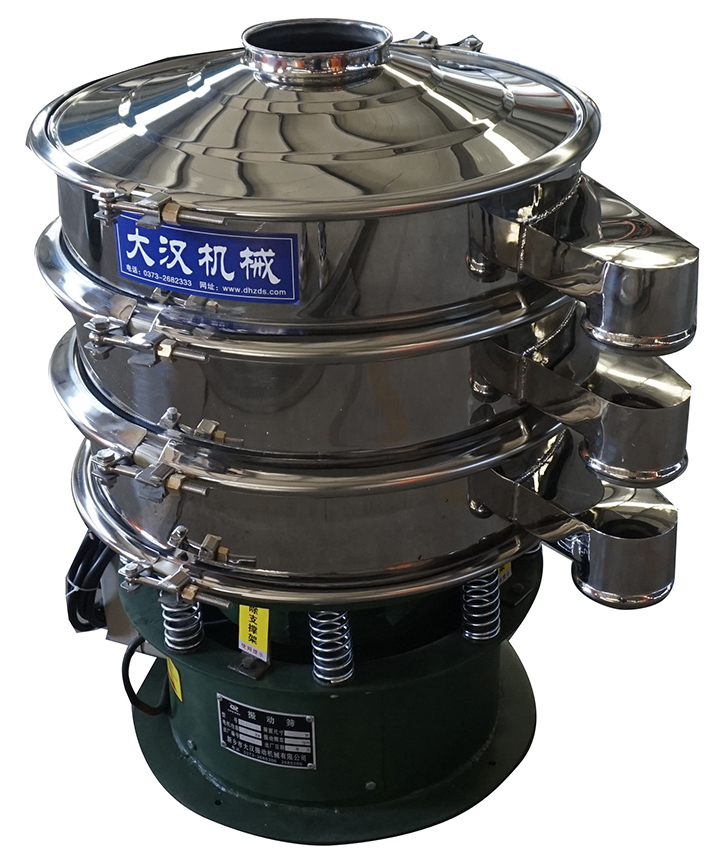

Grain sieves

The price of the grain sieves is $20 to $600/Set,It is widely used in the removal and sorting of various grains such as wheat, corn, rice, etc. to improve the quality of grains.

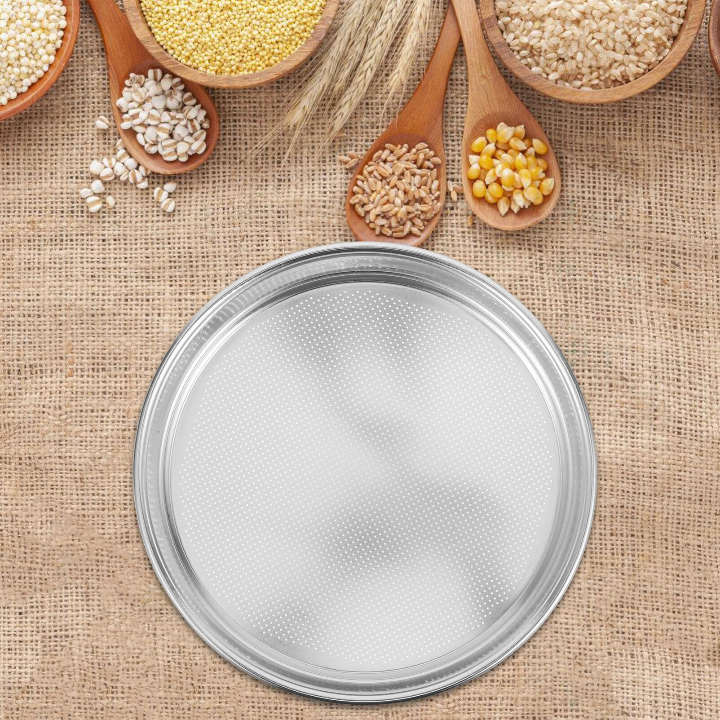

measure range:20µm-125mm

Diameter:75mm, 100mm, 200mm, 300mm

Hole type:square hole, round hole

Material: Stainless Steel 304/316L,brass

Applicationwheat, barley, soybean, corn, rice, rye, oats,etc.

What is Grain Sieves?

Grain Sieves are screening equipment used for grain grading, cleaning and impurity removal. They are driven by a vibrating motor to make wheat, corn, rice and other grains move regularly on the sieve surface, and use sieves of different meshes to separate impurities and grain particles of different sizes. They are widely used in farms, grain processing plants and grain storage. The sieve of the grain sieve can be adjusted according to the size of the grain particles. For example, wheat particles are fine (2-3mm) and easy to be mixed with concrete crumbs, so a 10-20 mesh fine sieve is required with high-frequency vibration to remove impurities; corn particles are coarse (5-8mm) and often carry straw, so a 5-10 mesh coarse sieve plus an inclined sieve surface is suitable for rapid separation by gravity.

The selection of grain sieves should be based on the characteristics of grains. In view of the smooth surface of wheat, the equipment needs to be equipped with a screen with an anti-stick coating to reduce clogging; corn has high hardness and strong abrasion resistance, and 304 stainless steel or manganese steel screens are required to extend the life; rice contains fine impurities such as broken rice and barnyard grass, and multi-layer screens should be configured to simultaneously complete coarse screening, fine screening and impurity removal to ensure screening efficiency.

How are Grain Sieves classified?

Grain Sieves are mainly divided into two types: pest selection screens and grain selection screens.

Pest selection screens: mainly used to separate insect-infested grains, live insects and eggs in grains, to help determine the degree of grain pests, usually using small-aperture screens (such as 1-3mm), and separating pests from intact grains through vibration or rotation, suitable for pest screening before storage or processing.

Grain selection screens: The main function is to remove impurities from grains and classify them. It usually uses multi-layer screens (2-3 layers) to accurately separate impurities, broken grains, and shrunken grains according to the particle size of different grains. It is suitable for screening and removing impurities of different crops such as wheat and rice to improve the purity and quality of grains.

What are the advantages of Grain Sieves?

Grain Sieves screening efficiency is much higher than manual sorting, and can quickly process large quantities of grains; the grading accuracy is more stable, and it can reduce the problem of missed screening or wrong screening compared to simple sieves; it has strong adaptability and can cope with different grains by replacing the screen; it is durable and resistant to corrosion, and the screen frame screen is made of 316L stainless steel, which has a lifespan of more than 3 times longer than that of ordinary carbon steel screens and can adapt to humid environments. It is easy to maintain and has a simple structure, which can save cleaning and maintenance time; it has strong mobility, light weight and multi-wheel design, which is more suitable for multi-site operations than large fixed screens.

Parameter of Grain Sieves

| No. | Technical | Technical indicate |

| 1 | Sieve Diameter | 200mm 8inch/300mm 12inch/100mm4inch/75mm 3inch |

| 2 | Material | Stainless steel or Brass |

| 3 | Inner height | 50mm and 60mm |

| 4 | Aperture size range | 0.02mm to 125mm |

| 5 | Hole model | Wire mesh and perforated plate |

| 6 | Detail aperture | 125, 106, 100, 90, 75, 63, 53, 50, 45, 37.5, 31.5, 25, 22.4, 19, 16, 13.2, 12.5, 11.2, 9.5, 8, 6.7, 6.3, 5.6, 4.75, 4, 3.35, 2.8, 2.36, 2, 1.7, 1.4, 1.18, 1, 0.85, 0.71, 0.6, 0.5, 0.425, 0.355, 0.3, 0.25,0.212, 0.18, 0.15, 0.125, 0.106, 0.09, 0.075, 0.063, 0.053, 0.045, 0.038mm etc. |

| 7 | Use | Grading Standard Testing Sieve Test Sieve for soil test sieve, aggregate sieve, concrete test sieve, cement test sieve, asphalt test sieve, wet sieve, wire mesh sieve, perforated sieve, astm sieve, en sieve |

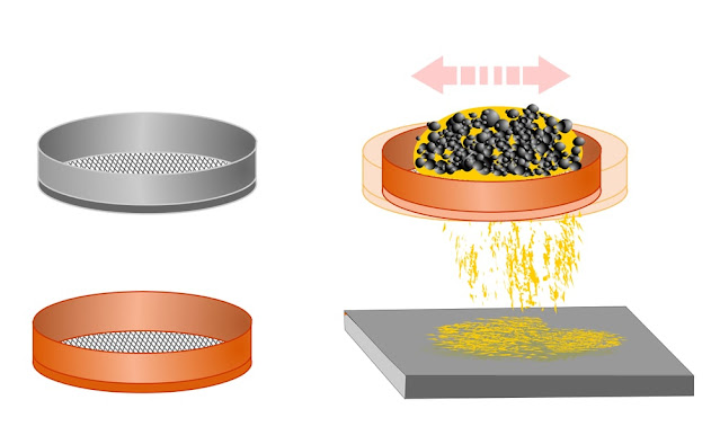

What is the working principle of Grain Sieves?

The working principle of the grain sieve is to drive the screen to produce regular movement through a vibration motor, so that the grains continue to roll and slide on the screen surface. Grain particles smaller than the mesh size (such as broken rice, bran, insect-eaten grains and other impurities) will pass through the mesh and eventually be discharged from the impurity outlet at the bottom; while intact grains larger than the mesh size (such as rice, wheat, etc.) will remain on the sieve surface and eventually be collected from the outlet on the other side to complete grading and impurity separation.

What are the applications of Grain Sieves?

Grain sieves are widely used in many fields, such as grain procurement points regularly use grain sieves to check the quality of stored grains to prevent pests or mildew; food processing companies need to sieve grains to obtain uniform flour or grain raw materials to improve product quality; in feed production, corn, soybeans and other raw materials are removed from moldy grains and impurities through grain sieves to ensure feed hygiene standards; seed breeding bases use grains to screen full grain seeds to ensure seed germination rate and purity; in grain and oil export trade, grain sieves can accurately control grain particle size and impurity content, help products meet international quality inspection requirements, and ensure export competitiveness.

Grain screens are key equipment for grain cleaning, grading and impurity removal. The equipment selection must strictly match the characteristics of the grain (e.g. wheat needs a fine anti-blocking screen, corn needs a wear-resistant coarse screen, and rice needs a multi-layer screen). Its advantages are high screening efficiency, stable grading accuracy, strong adaptability, durability and corrosion resistance, easy maintenance and flexible mobility. Its application runs through the grain industry chain. In grain procurement and storage, food processing, feed production, seed breeding, and grain and oil export trade, it plays an indispensable role in ensuring food safety and hygiene, improving product quality, meeting germination rate requirements, and complying with international quality inspection standards.