Vertical Packaging Machine for Liquid Sauce

According to the specifications of the packaging bag and the fluidity of the material, the output of Vertical Packaging Machine for Liquid Sauce is usually between 20 and 60 bags per minute, which is suitable for medium and large-scale production needs. The price range of Vertical Packaging Machine for Liquid Sauce is usually between US$1,000 to US$45,000.

Bag Shape: Back Sealing / 3 Sides Sealing / 4 Sides Sealing

Packing Speed: 30~80 bags/min

Roll Width: Max.200mm

Bag Length: 30~180 mm

Bag Width: 15~100 mm

Machine Size: L)640*W)700*H)1580mm

Machine Weight: 300kg

What is Vertical Packaging Machine for Liquid Sauce?

Vertical Packaging Machine for Liquid Sauceis suitable for high-viscosity sauces, semi-fluids and low-viscosity liquid materials. Such as ketchup, salad dressing, honey, cooking oil, sauce, jam, shampoo, shower gel and other products with different viscosities. The equipment adopts PLC control system and touch screen operation interface, supporting three-side sealing, four-side sealing, back sealing and other bag types. According to the specifications of the packaging bag and the fluidity of the material, the output of Vertical Packaging Machine for Liquid Sauce is usually between 20 and 60 bags per minute, which is suitable for medium and large-scale production needs.

In terms of working mode, the Vertical Packaging Machine for Liquid Sauce adopts a vertical continuous operation mode, fills the sauce into the packaging film through a liquid pump or a piston-type quantitative system, and achieves rapid sealing through a heat sealing system. The whole process is fast and continuous, and the equipment is equipped with an anti-drip filling valve to ensure clean sealing; the servo control system is adopted to achieve accurate positioning and stable operation.

Main features of Vertical Packaging Machine for Liquid Sauce

Vertical Packaging Machine for Liquid Sauce has the characteristics of high-precision filling (±1% error), anti-drip design, fully automated production, diversified packaging, wide material adaptability and easy cleaning and maintenance, which is suitable for the packaging of various liquid sauces.

High-precision filling: adopt high-precision flow meter or servo pump control to ensure that the filling amount of each package of sauce is consistent, and the error is controlled within ±1%.

Anti-drip design: For high-viscosity materials (such as peanut butter and sesame paste), the equipment is equipped with an anti-drawing filling valve to avoid residual materials at the sealing point and improve the packaging aesthetics.

High degree of automation: fully automatic from bag making to sealing, reducing labor costs and improving production efficiency.

Diversified packaging: supports a variety of bag types such as back seal, three-side seal, four-side seal, and can customize packaging bags of different sizes.

Wide material adaptability: compatible with composite film materials such as PE, PET, and aluminum foil to meet the preservation and sealing requirements of different products.

Easy to clean and maintain: The equipment is made of stainless steel, meets food-grade hygiene standards, and the structural design is easy to disassemble and clean.

Vertical Packaging Machine for Liquid Sauce Specifications

| Model NO. | BC-320 |

| Measuring | Liquid Filling Pump |

| Bag Shape | Back Sealing / 3 Sides Sealing / 4 Sides Sealing |

| Packing Speed | 30~80 bags/min |

| Roll Width | Max.200mm |

| Bag Length | 30~180 mm |

| Bag Width | 15~100 mm |

| Machine Size | L)640*W)700*H)1580mm |

| Machine Weight | 300kg |

| Power | 220V,50HZ,1.2KVA |

Vertical Packaging Machine for Liquid Sauce Packaging Bag Types

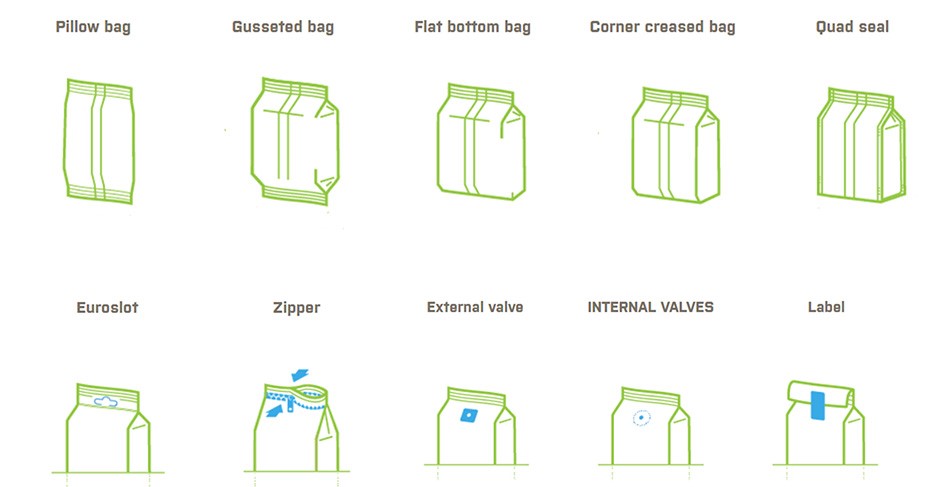

Vertical Packaging Machine for Liquid Sauce can be used for a variety of packaging bag types: Pillow bag is sealed on both sides and looks like a pillow. It is often used for packaging snacks, biscuits, etc. Gussered bag has a folding structure on the side to expand the capacity and is suitable for powder or granular products. Flat bottom bag has a flat bottom and can be placed upright. It is often used for coffee, pet food, etc. Corner creased bag has pre-pressed creases on the corners to facilitate opening. It is commonly used in gift packaging. Quad seal is sealed on all four sides to enhance protection and is used for high-end food or medical products. In addition, Euroslot is convenient for retail hanging display; Zipper can be repeatedly sealed to improve convenience, such as snack bags; External valve is used for external inflation port of air cushion packaging; Internal valves are common internal one-way valves for vacuum packaging; Label is used for product information identification or barcode pasting.

Vertical Packaging Machine for Liquid Sauce Price Range

The price range of Vertical Packaging Machine for Liquid Sauce is usually between $1,000 and $45,000, and the specific price is affected by factors such as equipment function, configuration, capacity, material, and expected output.

Basic equipment: The price is between $1,000 and $2,200, which is suitable for small-scale production or companies with limited budgets. This type of equipment generally has an hourly output of about 200-800 bags (the specific output varies depending on packaging specifications, sauce characteristics, etc.). This type of equipment usually has basic bag making, filling and sealing functions.

Mid-range equipment: The price is between $2,000 and $6,000, which is suitable for medium-scale production needs. Its hourly output is roughly between 800-2500 bags. This type of equipment has improved automation, packaging speed and accuracy, and may also have some additional functions, such as digital display, automatic counting, etc.

High-speed equipment: The price is between US$6,000 and US$45,000. It is suitable for large-scale production or enterprises with high requirements for packaging quality and efficiency. The equipment can produce more than 2,500 bags per hour, and some high-performance equipment can even reach 5,000 bags or even higher. This type of equipment usually has the characteristics of high automation, high-speed packaging, high-precision metering, etc., and may also be equipped with advanced functions such as intelligent control systems and multiple packaging styles.

Vertical Packaging Machine for Liquid Sauce Application Field

Vertical Packaging Machine for Liquid Sauce is widely used in food, daily chemicals, medicine and industrial fields. In the food industry, this equipment is suitable for the automatic packaging of condiments and sauces such as ketchup, chili sauce, soy sauce, vinegar, honey, jam, cream, etc., ensuring sealing and leakproof, and extending the shelf life; in the daily chemical industry, it can be used for accurate quantitative filling of liquid or paste products such as shampoo, shower gel, hand soap, skin cream, etc., to improve production efficiency and packaging consistency; in the pharmaceutical field, it can meet the aseptic packaging needs of medical supplies such as ointments, gels, disinfectants, etc., meet strict hygiene standards, and avoid pollution; in industrial applications, it can also complete the quantitative packaging of fluids with different viscosities such as lubricants and glues.

Vertical Packaging Machine for Liquid Sauce Supplier

Our factory has rich experience in manufacturing vertical packaging equipment for sauces. The main advantages in the production of Vertical Packaging Machine for Liquid Sauce include: Our factory can customize the design according to the customer's packaging needs, material characteristics, equipment size, sealing method, depth of metering range, etc., and provide a complete set of sauce packaging solutions. The company widely serves many domestic and foreign condiment brand companies and has successful cases for reference.

Vertical Packaging Machine for Liquid Sauce is an automated packaging equipment suitable for food, daily chemicals, medicine and other industries. The equipment is designed for fast and accurate small bag packaging of various liquids and sauces, and supports a variety of bag types. Its high automation, high compatibility and excellent hygiene performance make it have a wide range of application prospects in the food, condiment and catering industries. With advanced technology and high-quality services, our factory provides customers with cost-effective packaging solutions. Whether it is a small or medium-sized enterprise or a large manufacturer, you can find a model that suits your needs, thereby improving production efficiency and reducing operating costs.