Vertical Packaging Machine for Coffee Beans Packing

Vertical Packaging Machine for Coffee Beans Packing integrates weighing, bag making and sealing. It is suitable for 20g-1kg, 30-60 bags/minute, moisture-proof and aroma-preserving. The price is about US$7,000-20,000. Packaging type: self-supporting bag, flat bag, special-shaped bag customization Speed: 20~60 bags/minute (adjustable) Packaging range: 50~500g/bag (supports other specifications customization) Film material compatibility: PET/AL/PE composite film, kraft paper, degradable film Sealing method: four-side seal/back seal/with vertical ribs Measuring accuracy: ±0.5~1.5% (high-precision weighing) Power supply: 220V/380V, 50/60Hz, power 2~5kW Function: PLC control, touch screen operation, optional nitrogen filling for freshness Size: about 1200×800×1800mm (customizable)

What is Vertical Packaging Machine for Coffee Beans Packing?

Coffee beans are mostly packaged using vertical packaging machines. Vertical Packaging Machine for Coffee Beans Packing has the advantages of high degree of automation, simple operation, stable efficiency, etc. The equipment integrates weighing, bag making, filling and sealing. The equipment is suitable for bag widths of 80–250mm and packaging weights of 20g–1kg, meeting a variety of packaging needs. The output can reach 30–60 bags/minute, the price range is US$5,000–10,000, and the configuration is flexible. Common packaging forms include four-seal bags, stand-up bags, and gusseted bags. They are made of aluminum foil composite film, have excellent sealing performance, can effectively prevent moisture and preserve aroma, and significantly improve the preservation effect and product grade of coffee beans.

Vertical Packaging Machine for Coffee Beans Packing adopts an automated assembly line design. After the empty bag is accurately positioned by the automatic bagging device, the quantitative filling of coffee beans is completed by the metering system, and then the freshness is optimized by the vacuum or nitrogen filling device, and the heat sealing technology is used to ensure the sealing of the packaging. Finally, the date coding and finished product output are automatically completed.

What types of materials are packaged by Vertical Packaging Machine for Coffee Beans Packing?

Coffee products mainly involve three types of material forms according to the processing method: granular, powdered and blocky. Vertical Packaging Machine for Coffee Beans Packing is suitable for the above different forms of materials.

Granular: such as roasted coffee beans, the particles are uniform, the surface is smooth, the fluidity is good, and the material is easy to discharge. Usually, a multi-head electronic combination scale is used for high-precision measurement (accuracy can reach ±0.5g), or a measuring cup is used for volumetric measurement, and the material discharge efficiency can reach 60-80 bags/minute, which is suitable for high-speed production lines.

Powder: such as ground coffee powder, the texture is fine, easy to agglomerate, and the fluidity is poor. It is necessary to equip the spiral discharge mechanism (screw diameter 30-50mm) with a vibration device to avoid blockage and powder spraying problems. The air pressure balance needs to be controlled during filling to ensure that the accuracy is stable within ±1g.

Block or mixture: such as sugary coffee blocks, flavored particles, etc., with large density differences (0.3-1.2g/cm³) and irregular shapes. A flexible discharge system (such as belt conveyor or robot gripper) needs to be customized, and multi-stage vibration screening is required to ensure that the material is evenly distributed and not broken, and the compatibility requirements are higher.

Features of Vertical Packaging Machine for Coffee Beans Packing

Vertical Packaging Machine for Coffee Beans Packing has the characteristics of small footprint, fast and accurate, and applicable to different bag types in terms of structure and function. The detailed features are as follows:

Space saving: The vertical structure is compact and occupies a small area, which is suitable for small production lines or factories with limited space.

Fast and accurate: The servo drive and high-precision metering system are used to ensure that the weight error of each bag of coffee beans is ≤±1%, and the packaging speed can reach 60 bags/minute, which meets the needs of large-scale production.

Multi-specification adaptation: The modular design supports a variety of bag types from 50g to 1kg (self-supporting bags, four-side seals, back-seal bags, etc.), and one-button parameter switching can flexibly respond to different packaging specifications.

Freshness protection: Equipped with nitrogen replacement function, residual oxygen content ≤1%, effectively extending the shelf life of coffee beans; built-in anti-static device to avoid powder adsorption and contamination of the seal.

Intelligent control: Touch screen PLC operating system, preset recipe memory, fault self-detection and production statistics functions, support remote monitoring, and reduce manual intervention.

Durable and hygienic: The contact parts are made of food-grade 304 stainless steel, which meets GMP standards; the fully sealed structure design is dust-proof and moisture-proof, and is easy to clean and maintain.

Vertical Packaging Machine for Coffee Beans Packing Specifications

| Model | SF8-220 | SF8-250 | SF8-300 |

| Equipment material | 304 stainless steel | ||

| Heat sealing | twice sealing | ||

| Packing speed | 20-60bags/min | 20-50bags/min | 20-45bags/min |

| Pouch dimension | W: 65-200mm L: 65-400mm | W: 70-250mm L: 70-450mm | W: 200-300mm L: 200-450mm |

| Filling range | 5-1500g | 10-2000g | 100-2500g |

| Voltage & power | 380V, three phase, 50HZ, 5KW | ||

Vertical Packaging Machine for Coffee Beans Packing Price

Choosing a suitable Vertical Packaging Machine for Coffee Beans Packing requires comprehensive consideration of production scale, functional requirements and budget. The following is an analysis of the characteristics and applicable scenarios of equipment at different production levels:

Small production model: The output is 50-200 bags per hour. This model has basic metering, bag making and sealing functions, can adapt to packaging bags of different specifications, and is easy to operate. The price is around US$3,000-8,000, which is suitable for small coffee shops or start-up coffee bean processors.

Medium production model: 200-500 bags per hour. In addition to basic functions, it adds practical functions such as automatic nitrogen filling and fresh-keeping, inkjet printing (production date/batch number), and higher packaging accuracy. The equipment is highly stable and the price is in the range of 8,000 to 15,000 USD, which can meet the daily production needs of general coffee bean processing plants.

Large-scale production model: more than 500 bags per hour, comprehensive functions, integrated intelligent control system, remote monitoring and fault diagnosis, and extremely high production efficiency. The price is usually more than 15,000 USD, suitable for large coffee production companies.

Vertical Packaging Machine for Coffee Beans Packing Application

Vertical Packaging Machine for Coffee Beans Packing is widely used in the field of coffee bean packaging, mainly covering the following scenarios:

Commercial coffee production: suitable for large, medium and small coffee roasters, efficient completion of quantitative packaging (such as 250g, 500g, 1kg, etc.), to ensure sealing and freshness, and extend the shelf life of coffee beans.

Boutique coffee and single-origin beans: support small batch and multi-specification packaging to meet the high-end market's demand for customized packaging, such as nitrogen filling or modified atmosphere packaging to maintain flavor.

Retail and e-commerce: Automated packaging improves efficiency, adapts to different bag types (stand-up bags, four-side sealing bags, etc.), and is compatible with labeling, coding and other functions, which facilitates brand display and traceability.

Catering and hotel supply: Provide large-capacity packaging (more than 5kg) for B-end customers to ensure convenient transportation and storage stability.

Export trade: Meet international hygiene standards and adapt to moisture-proof and anti-oxidation requirements for long-distance transportation.

Production efficiency of Vertical Packaging Machine for Coffee Beans Packing

In the actual production process, the operating efficiency of the vertical packaging machine is affected by many factors, including material type, packaging bag size, metering system accuracy, etc. The production efficiency of different types of coffee materials is as follows:

Granular coffee beans

Recommended configuration: 10-head electronic combination scale

Packaging speed: about 40-60 bags/minute

Daily output (8 hours): about 19,000-28,000 bags/day

Features: smooth feeding, accurate metering, suitable for high-speed mass production, commonly used in standard coffee bean packaging lines

Powdered coffee

Recommended configuration: spiral feeding system with dustproof structure

Packaging speed: about 25-40 bags/minute

Daily output (8 hours): about 12,000-19,000 bags/day

Features: The powder has poor fluidity, the feeding speed is slightly slower, and effective dust and blockage prevention are required. It is suitable for ground coffee packaging with medium production capacity requirements

Block or mixed coffee materials

Recommended configuration: customized multi-channel feeding structure

Packaging speed: about 20-35 bags/minute

Daily output (8 hours): about 9,500–16,000 bags/day

Features: The material particles are of different shapes, and the material needs to be stable and avoid breakage. It is suitable for packaging lines with high added value or special flavor mixed products

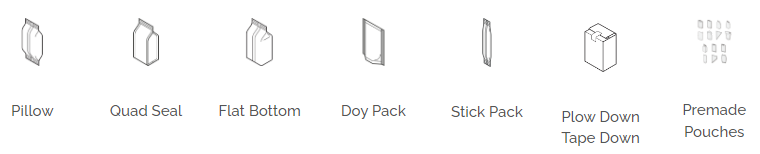

What are the packaging bag forms of Vertical Packaging Machine for Coffee Beans Packing?

The core goal of coffee packaging is to prevent moisture, oxidation, and UV rays to ensure that the flavor does not lose. Aluminum foil composite film or PE/PET composite material is usually used, which has good air tightness and strength. There are various packaging forms:

Prefabricated bags: pre-made, the open end is to be sealed, the structure is simple, the production efficiency is high, and it is suitable for automatic packaging. Commonly used in food, daily chemical and other industries, it needs to be used with a filling machine. In coffee bean packaging, prefabricated bags are suitable for mass production, can be quickly filled and sealed, and are suitable for mid- and low-end coffee bean products, saving packaging costs.

Flat-bottom bag: The bottom is flat, with strong uprightness, stable placement, and large capacity. It is mostly used for gifts, clothing and other goods that need to be displayed, with a neat and beautiful appearance. In coffee bean packaging, flat-bottom bags are often used for boutique coffee or gift packaging. They are placed upright for easy shelf display and improve product grade.

Four-seal bag: four-side sealed, fully enclosed structure, excellent moisture-proof and leak-proof performance. Commonly used in electronic products, medicines and other products with high requirements for sealing, with good safety. In coffee bean packaging, four-seal bags can effectively isolate oxygen and moisture, extend the shelf life of coffee beans, and are suitable for high-end or long-term storage products.

Pillow bag: The middle seam is sealed, the two ends are heat-sealed, pillow-shaped, and flexible. It is widely used in snacks, puffed foods, etc., suitable for high-speed packaging machines, and has low cost. In coffee bean packaging, pillow bags are suitable for economical products, with high production efficiency, and suitable for supermarkets and other distribution channels.

Vacuum brick bag: After vacuuming, it forms a brick shape, saves space, has strong barrier properties, and extends the shelf life. It is mainly used for foods that need to be kept fresh, such as meat and coffee, and the material is mostly multi-layer composite film. Vacuum brick bags can maximize the freshness of coffee in coffee bean packaging, and are suitable for long-distance transportation or long-term storage.

Gusseted bags: Add folds on both sides of the bag to enhance the three-dimensional sense and capacity, and facilitate stacking and display. They are often used for medium-sized coffee products, such as convenience stores or supermarkets. In coffee bean packaging, gusseted bags take into account both capacity and beauty, are suitable for the mid-range market, and are easy to display on shelves.

Self-supporting bags (with zippers): The bottom can be unfolded and self-supporting, and the zipper design is convenient for opening and resealing. It is suitable for boutique coffee, home or high-end market sales, and enhances brand image and user experience. Self-supporting bags combine convenience and quality in coffee bean packaging. The zipper design is convenient for multiple use, which is suitable for home or office scenes.

Some mid-to-high-end packaging is also equipped with a one-way exhaust valve to prevent packaging expansion and release coffee ripening gas at the same time. In terms of machine parameters, the Vertical Packaging Machine for Coffee Beans Packing supports bag widths of 80–250mm and bag lengths of 100–350mm. The control system uses PLC+touch screen, supports multi-language operation, and the error is controlled within ±1%. Expandable functions include coding, labeling, exhaust valve packaging, etc., to meet different market and customer needs.