Vertical Form Fill Seal Packing Machines

Vertical Form Fill Seal Packing Machines can automatically complete the bag forming, product filling and sealing processes. The price varies depending on the function and model, ranging from $4,000 for the entry-level to $25,000 for the multi-functional high-end model. Bag making method: vertical back seal type Applicable materials: powder/granules Packing speed: 30-70 bags/minute Bag size: 50-180mm wide

Voltage power: 220V/2.2KW Control system: PLC intelligent control Material structure: stainless steel body

What are Vertical Form Fill Seal Packing Machines?

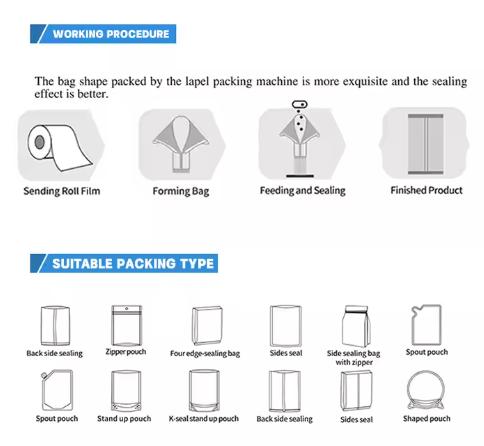

Vertical Form Fill Seal Packing Machines can automatically complete the bag forming, product filling and sealing processes. Its working process is: the film is formed and sealed by the guide roller, and the material is filled into the bag and then transversely sealed and cut to complete the automatic packaging into bags. The packaging speed is about 30-80 bags/minute, the packaging range is about 5g-2kg, and the sealing methods are heat sealing and cold sealing. The output is affected by the product characteristics and bag type, and is generally 1800-4000 bags/hour. The price varies depending on the function and model, ranging from $4,000 for the entry-level to $25,000 for the multi-functional high-end model.

Vertical Form Fill Seal Packing Machines packaging system usually includes forming device, metering device, filling device and sealing device to ensure the sealing and aesthetics of the packaging. In addition, Vertical Form Fill Seal Packing Machines equipment is equipped with advanced control system to achieve precise control and data monitoring, improve production efficiency and product quality.

What types of Vertical Form Fill Seal Packing Machines are there?

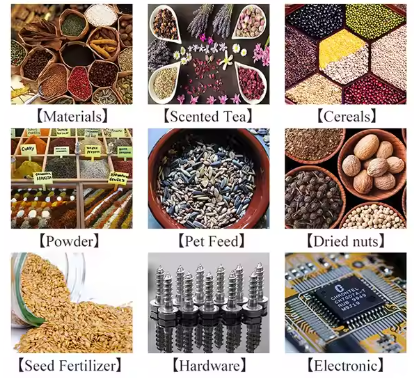

Vertical Form Fill Seal Packing Machines are divided into the following five types of packaging machines according to different types of materials: granules, powders, liquids, pastes, and mixed materials.

VFFS packaging machines for granular materials use measuring cups, combination scales or linear scales for measurement. The structural design conforms to the natural fall of granules to prevent material jams. It supports mixed packaging of multiple granules and is suitable for granular products such as candy, beans, and pet food. The packaging speed is 30-80 bags/minute.

VFFS packaging machines for powder materials are equipped with screw or vibration feeding devices, and have dust-proof, anti-static and enhanced sealing structures to ensure clean and complete packaging. They are suitable for fine powders with poor fluidity such as milk powder and chemical powder. The packaging speed is 25-60 bags/minute.

VFFS packaging machines for liquid materials use gear pumps, magnetic pumps or piston pumps for precise filling. They have anti-drip and hot and cold double sealing structures. They are suitable for low to medium viscosity liquids such as soy sauce and detergents. The packaging speed is 30-70 bags/minute.

The VFFS packaging machine for paste materials uses a piston pump or pneumatic filling system, with optional heating devices to maintain fluidity and nozzles to prevent contamination. It is suitable for high-viscosity products such as ketchup and honey, and the packaging speed is 20-50 bags/minute.

The VFFS packaging machine for mixed materials is equipped with a multi-channel feeding system, integrating a variety of metering devices to achieve simultaneous quantitative and packaging of materials in different forms. It is suitable for combined products such as seasoning sauce + vegetables, nuts, etc. The packaging speed is 20-60 bags/minute, depending on the complexity of the material.

The difference between vertical and horizontal packaging machines

Vertical packaging machines (VFFS) are suitable for materials with good free flow, high efficiency, small footprint, and are suitable for bulk particles, powders, liquids, etc. Horizontal packaging machines (HFFS) are more suitable for regular objects such as biscuits, soaps, paper towels, etc., with various packaging forms and beautiful sealing. The center of gravity of the vertical machine is concentrated downward, which is suitable for gravity filling; the horizontal machine pushes the material horizontally and pays more attention to the appearance of the packaging. The selection should be flexibly configured according to the product status and production site.

What are the Advantages of Vertical Form Fill Seal Packing Machines?

Vertical Form Fill Seal Packing Machines integrate vertical structure, precise filling and efficient sealing, and have multiple advantages.

The vertical design occupies a small area and uses gravity to feed materials naturally. It is suitable for a variety of materials such as granules, powders, liquids, etc., and runs stably and quickly.

The filling system can choose spiral metering, electronic scales or liquid pumps to ensure accurate metering and high packaging consistency.

The sealing system supports longitudinal and transverse sealing, adjustable temperature, adaptable to a variety of film materials, firm and beautiful sealing, and effectively prevents leakage.

What are the types of packaging bags for Vertical Form Fill Seal Packing Machines?

Vertical Form Fill Seal Packing Machines are divided into pillow bags, three-side sealed bags, four-side sealed bags, gusseted bags, stand-up bags, and connected bags.

Pillow bags (back-sealed bags) are the most common packaging form, with a middle seal on the back, a flat bag shape, fast forming, high production efficiency, and low cost. They are suitable for products such as granules, solids, and powders, and are widely used in large-scale packaging of food and industrial products.

The three-side sealed bag is sealed on three sides and one side is open for filling. It has good sealing and strong stability. It is suitable for liquid and powder products, such as seasoning sauces and medicinal powders, and can prevent leakage and contamination.

The four-side sealed bag adopts a symmetrical structure with four-side sealing, neat edges and regular bag shape. It is often used for fine foods and health products.

The corner-inserted bag (eight-side sealed bag) has four corners inserted and top and bottom seals, a total of eight sides are sealed, the bag shape is three-dimensional, and the visual effect is good. It is often used for nuts, pet food, and coffee beans packaging.

The vertical bag has a bottom support design and can stand independently. It is often equipped with zippers or nozzles. It is easy to use and suitable for sauces and liquid products, such as jams, laundry detergents, beverages, etc.

The connected bag is connected by multiple small bags with easy-tear lines or heat seals, which is convenient for subpackaging and combined sales. It is suitable for trial packs and small packaged seasonings to meet the needs of promotion and split use.

The difference between horizontal sealing and vertical sealing

Horizontal sealing and vertical sealing are two key sealing processes in the packaging and bag making process. Their differences are mainly reflected in three aspects: sealing direction, functional positioning and quality impact:

Horizontal sealing: that is, the horizontal sealing completed by the upper and lower heat seals, which determines the sealing effect of the upper and lower edges of each bag.

Vertical sealing: heat-seal the left and right sides of the packaging film longitudinally to form a cylindrical bag.

Vertical sealing affects the stability of bag forming. If the seal is not good, it will cause air leakage or powder leakage; horizontal sealing is related to the overall appearance and sealing quality. Only when the two are properly coordinated can high-quality packaging be achieved.

Parameters of Vertical Form Fill Seal Packing Machines

| Model | VP-420 | VP-520 | VP-620 | VP-730 | VP-800 | VP-1050 |

| Bag Size | (L)70-300mm (W)60-200mm | (L)80-350mm (W)100-250mm | (L)80-400mm (W)140-350mm | (L)200-450mm (W)140-350mm | (L)150-500mm (W)250-400mm | (L)20-500mm (W)140-500mm |

| Output | 10-70 BPM | 15-60 BPM | 15-60 BPM | 10-50 BPM | 5-30 BPM | 2-30 BPM |

| Film Width (mm) | 120 ~ 420 | 220 ~ 520 | 220 ~ 620 | 300 ~ 720 | 340 ~ 800 | 300 ~ 1050 |

| Film Thickness (mu) | 30 ~ 100 | 40 ~ 100 | 40 ~ 100 | 50 ~ 120 | 60 ~ 150 | 70 ~ 200 |

| Air Consumption | 0.5m3 per min | 0.4m3 per min | 0.4m3 per min | 0.5m3 per min | 0.7m3 per min | 0.7m3 per min |

| Machine Dimensions (mm) | 1530x970x1600 | 1430x1200x1700 | 1430x1200x1700 | 1340x1580x1950 | 1500x1680x2100 | 1740x2080x2500 |

| Weight (Kg) | 450K | 680 | 700 | 800 | 1000 | 1200 |

| Power | 2.2kW (220V- 50/60Hz) | 2.5kW (220V- 50/60Hz) | 2.5kW (220V- 50/60Hz) | 2.5kW (220V- 50/60Hz) | 3kW (220V- 50/60Hz) | 3kW (220V- 50/60Hz) |

Industry solutions for Vertical Form Fill Seal Packing Machines

Vertical Form Fill Seal Packing Machines have shown good adaptability and high performance in the food, chemical and pharmaceutical industries. In the food industry, the equipment uses a 304 stainless steel body to ensure high hygiene standards, and is equipped with a quick mold change design, which can quickly switch between different bag types and reduce downtime. The chemical industry focuses on corrosion and leakage prevention. The equipment uses PE coil packaging, which is resistant to chemical corrosion, and uses heat sealing technology to ensure seamless sealing of the bag mouth. It is also equipped with a dust collection system to reduce environmental pollution. The pharmaceutical industry requires a sterile environment and precise filling. VFFS uses an oil-free vacuum pump and clean room design to ensure Class A cleanliness, and supports aluminum foil composite film to extend the shelf life of drugs. Through these designs, VFFS can meet the high standards of packaging equipment in various industries.

Differences between forming, filling and sealing machines

The three are different links in the packaging process:

Forming machine: folds the packaging film or material into a bag shape, often combined with a sealing function.

Filling machine: accurately delivers the material to the formed packaging bag, and the accuracy of the metering system affects the packaging consistency.

Sealing machine: seals the bag after forming and filling to ensure sealing and product preservation.

VFFS equipment integrates the three into one, achieving synchronous linkage, which is an important development direction of modern packaging equipment.

Application fields of Vertical Form Fill Seal Packing Machines

Vertical Form Fill Seal Packing Machines cover almost all industries that require small and medium-sized packaging, such as candy, frozen food, and seasonings in the food industry, and shampoo and shower gel in the daily chemical industry:

Food industry: such as candy, puffed food, instant powder, dried fruit, seasoning, frozen food, etc. Commonly used packaging bag types include pillow bags, gusseted bags, zipper bags, four-side sealed bags, etc.

Daily chemical industry: washing powder, shampoo, shower gel, small bag laundry beads, etc., commonly used packaging bag types include back-sealed bags, continuous bag packaging, standing bags, etc.

Pharmaceutical industry: powder medicines, granules, nutritional health products, etc., commonly used packaging bag types are three-side sealed bags, small strip bags, multi-link bags, etc.

Agricultural field: seeds, feed, small package fertilizers, etc., commonly used packaging bag types include pillow bags, gusseted bags, PE film composite bags, etc.

Industrial chemical industry: small bag desiccant, industrial powder, granular raw materials, etc., common packaging bag types include three-side sealed bags, back-sealed bags, anti-static composite bags, etc.

Price of Vertical Form Fill Seal Packing Machines

The price of Vertical Form Fill Seal Packing Machines is mainly affected by function, configuration and bag type.

Basic models such as VFFS-320 are suitable for powder and granule packaging. The maximum bag width can reach 160mm, the output is about 30-50 bags/minute, and the price is about $4,000-$6,000, which is suitable for small and medium batch production.

Mid-range models such as VFFS-420/520 have a wider range of adaptability, supporting a variety of materials such as granules, powders, and liquids. They are equipped with touch screens, servo motors, etc. The bag width can reach 250mm, and the output is increased to 40-60 bags/minute. The price is $8,000-$12,000, which is suitable for medium-capacity needs in daily chemical, food and other industries.

High-end models such as VFFS-620/720 support multi-column packaging, automatic weighing, batch number printing and other functions. The bag width can reach up to 350mm, and the output can reach 60-80 bags/minute. It is suitable for large-scale industrial production, and the price range is $15,000-$25,000. If equipped with automatic systems such as spiral metering devices, electronic scales, and bucket elevators, the total investment may exceed $30,000, which is suitable for the construction of high-efficiency automated packaging lines.

Vertical Form Fill Seal Packing Machines Manufacturer

Vertical Form Fill Seal Packing Machines integrate automatic metering, filling, and sealing, support a variety of packaging bag types, fast packaging speed, intelligent control system, easy operation, and strong stability. When manufacturing Vertical Form Fill Seal Packing Machines, our factory can customize them according to the requirements of function, output, model, etc. to meet the packaging needs of different industries and products. Our factory provides comprehensive after-sales service and technical support, supports trial operation with materials, helps customers quickly debug equipment, improve production efficiency, and ensure that the packaging achieves the ideal effect.