Sachet Filler & Packaging Machine

Sachet Filler & Packaging Machine can reliably fill materials of varying viscosities, such as aqueous solutions, emulsions, and gels. The typical bag capacity for a stand-up pouch is 5-50ml, for a three-side seal bag is 1-30ml, and for a four-side seal bag is 3-100ml. The production speed ranges from 30 to 60 bags per minute. Equipment prices range from $2,000 to $10,000. Packaging Speed: 30-60 bags per minute Metering Method: Screw/Piston/Weighing System Applicable Materials: Liquids, Powders, Granules Bag Dimensions: 30-150mm Width, 30-200mm Length Sealing Methods: Three-Side Seal, Four-Side Seal, Back Seal Construction: Stainless Steel Applicable Film Materials: PET/PE, NY/PE, and other composite films

What is a Sachet Filler & Packaging Machine?

The Sachet Filler & Packaging Machine typically packs liquids in capacities ranging from 1ml to 100ml, and powders and granules in capacities ranging from 1g to 100g. It is suitable for a variety of material forms, including liquids, pastes, and powders. Utilizing advanced metering technology, this machine achieves a filling accuracy of ±1%. It can reliably fill materials of varying viscosities, such as aqueous solutions, emulsions, and gels. The typical bag capacity for a stand-up pouch is 5-50ml, for a three-side seal bag is 1-30ml, and for a four-side seal bag is 3-100ml. The production speed ranges from 30 to 60 bags per minute. Equipment prices range from $2,000 to $10,000.

The typical workflow of a Sachet Filler & Packaging Machine is as follows: material is fed into the material channel via a metering device. The packaging material is rolled into a tube by a former and sealed longitudinally. The bottom of the bag is then sealed transversely. After the material falls into the bag, a station moves to complete the top seal. Finally, a cutter cuts the bag, completing the filling and packaging of the small bag.

Sachet Filler & Packaging Machine Features

The Sachet Filler & Packaging Machine performs multiple functions, including filling, sealing, and other functions. It supports bags of various materials and can be customized for different capacity ranges. Made of food-grade materials, the machine features high-precision filling, stable packaging, strong sealing, and high-precision slitting, supporting a wide range of customization options.

Structural Design: It includes film feeding, forming, filling, sealing, and slitting stations, integrating functions such as filling, metering, and multi-edge sealing. It boasts a compact design and a high degree of automation. Compatibility: The modular design supports a variety of bag types (back seal, three-side seal, four-side seal) and materials (aluminum foil, composite film), with customizable specifications (5-100 ml/g).Equipment Material: Contact parts are made of 316 stainless steel, and the frame is made of 304 stainless steel, meeting food-grade requirements, corrosion-resistant, and easy to clean.

Features:

Filling: Optional dual-tube simultaneous filling allows for layered or mixed filling. High-precision metering pump control with an error of ≤±1%.

Packaging: Automatic film roll tracking supports materials such as aluminum-plastic and composite film, with adjustable tension to ensure stable film flow.

Capping/Sealing: Heat or ultrasonic sealing ensures a strong seal and can accommodate custom shaped bags (such as stand-up pouches and spouted pouches).

Slitting: Servo-driven slitting ensures smooth cuts and supports slitting of linked bags or individual pouches, with a slitting accuracy of ±0.5mm.

Sachet Filler & Packaging Machine Specifications

| Sachet packaging machine | SP 200 | SP 400 | SP 600 |

|---|---|---|---|

| number of lanes | 1 – 8 | 2 – 14 | 2 – 20 |

| maximum format width | 240 mm | 420 mm | 600 mm |

| sachet width | 30 – 200 mm | 30 – 140 mm | 30 – 120 mm |

| sachet length | 40 – 200 mm | 40 – 200 mm | 40 – 200 mm |

| maximum film reel width | 480 mm | 840 mm | 1200 mm |

| maximum film reel diameter | 500 mm | 600 mm | 600 mm |

| performance | ≤ 100 cycles/min | ≤ 100 cycles/min | ≤ 100 cycles/min |

Sachet Filler & Packaging Machine Price Range

The price of Sachet Filler & Packaging Machine varies depending on factors such as model, function, capacity and material, and the price range is roughly between $2,000 and $20,000.

Economical model: The price is usually between $2,000 and $5,000. It is suitable for small-scale production or packaging of single liquid products (such as water and juice). The function is relatively basic, but it meets basic automation needs. The output is 30-60 packs per minute.

Mid-range model: The price is between $5,000 and $9,000. It supports the packaging of multiple types of liquids (such as honey, sauces, shampoo), and has automatic bag making, metering, filling, sealing, cutting and counting functions. Some models can be customized to print batch numbers. The speed can reach 100-200 packs per minute (according to different specifications).

High-end models: Priced over $9,000 and ranging up to $20,000, these machines are suitable for high-capacity, multi-format, or high-precision applications (such as those in the pharmaceutical and cosmetics industries). These machines are equipped with PLC control, touchscreen operation, intelligent temperature control, and multi-station synchronization. They feature multi-lane high-speed filling (300-500 bags/minute).

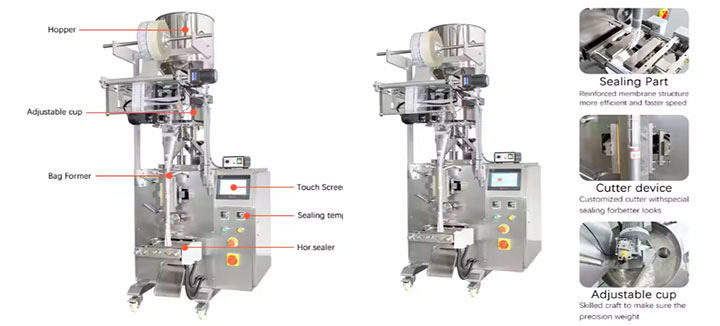

Sachet Filler & Packaging Machine Structure

Sachet filler & packaging machine primarily consists of a feeding system, metering device, bag-making system, filling system, sealing and cutting system, and control system. The feeding system transports material (such as powder, liquid, or granules) to the metering device, typically using a screw, pump, or vibrating feeder. The metering device controls the material quantity within a set accuracy to ensure consistent packaging volume in each bag. The bag-making system automatically folds and seals the film material to form the pouch. The filling system fills the pouch with the desired quantity of material. The sealing and cutting system heat-seals the pouch and cuts it into individual bags. The control system, through devices such as a PLC, automates the entire packaging process and provides fault detection.

Sachet Filler & Packaging Machine Bag Shapes

The Sachet Filler & Packaging Machine can produce a variety of small bag shapes, with packaging capacities ranging from 1 gram to 500 grams, to accommodate a wide range of material needs. Bag sizes are customizable, with common widths ranging from 30mm to 150mm and heights from 40mm to 200mm.

Three-Side Seal Bags: These bags are sealed on three sides and are suitable for packaging materials such as powders, granules, and liquids. They offer a strong seal and are effective in preventing moisture and leaks.

Four-Side Seal Bags: These bags are sealed on all four sides and have a square appearance. They are suitable for products requiring a higher level of sealing, such as pharmaceuticals and cosmetics, enhancing their quality.

Stand-Up Bags: These bags have a support structure at the bottom, allowing them to stand upright for easy display and sales. They are commonly used for packaging food and daily necessities.

Zipper Bags: These bags feature a zipper at the top for easy opening and closing, making them suitable for products that require repeated use, such as nuts and candies.

Special Shape Bags: Custom shapes, such as heart and circle, are designed to enhance the packaging's appeal and recognition, tailored to the product's characteristics.

Sachet Filler & Packaging Machine Solutions

The Sachet Filler & Packaging Machine has applications across the food, pharmaceutical, daily chemical, and agricultural sectors, offering tailored solutions. In the food industry, it can package chili sauce, honey, nuts, and more. It utilizes a multi-head weighing or plunger pump system for precise metering, while 3/4-side sealing technology ensures a tight seal. In the pharmaceutical sector, it supports counted packaging of tablets and capsules, achieving high-speed dispensing through photoelectric tracking and servo motor control. In the daily chemical industry, it can handle liquids such as shampoo and shower gel, equipped with corrosion-resistant stainless steel contact parts and an intelligent temperature control system. In the agricultural sector, it is used to package granular materials such as fertilizers and seeds, utilizing pneumatic control and anti-static design for enhanced stability.