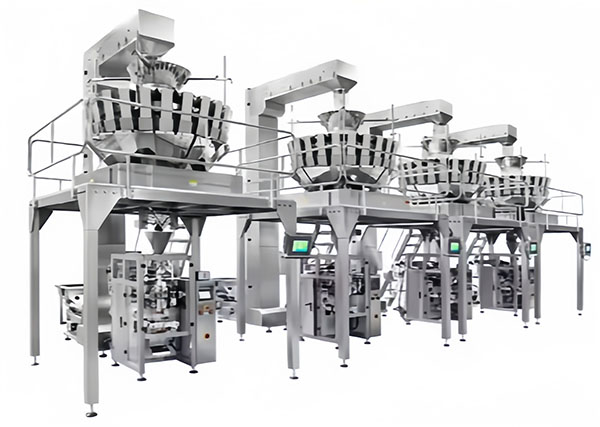

Double Feeding Vertical Packaging System

Double Feeding Vertical Packaging System supported bag types include three-side sealed bags, stand-up bags, zipper bags and special-shaped bags. The single-line production capacity reaches 30-60 bags/minute, with a packaging accuracy of ±0.5-1.5 grams, suitable for materials weighing between 10 and 6,500 grams. Depending on the complexity of the equipment configuration, the system price ranges from US$7,000 to US$50,000. Packaging speed: 30-60 bags/minute Packaging accuracy: 0.5-1.5 grams Packaging range: 10-6500 grams Packaging type: stand-up bag, zipper bag, etc. Control system: PLC control Applicable materials: granules, powders, liquids, sauces, etc. Automatic functions: filling, sealing, printing, etc. Material: stainless steel body, durable and corrosion-resistant

What is Double Feeding Vertical Packaging System?

Double Feeding Vertical Packaging System realizes the synchronous metering and packaging of granules, powders, flakes and irregular shaped materials (such as nuts, candies, freeze-dried foods, pet food, etc.) through dual-channel independent feeding design. The system adopts a modular structure and consists of four major components: vibrating feeder, Z-type conveyor, multi-head scale and vertical forming, filling and sealing machine. The supported bag types include three-side sealed bags, stand-up bags, zipper bags and special-shaped bags. The single-line production capacity reaches 30-60 bags/minute, with a packaging accuracy of ±0.5-1.5 grams, suitable for materials weighing between 10 and 6,500 grams. Depending on the complexity of the equipment configuration, the system price ranges from US$7,000 to US$50,000. High-end models are equipped with metal detection, weighing feedback, and visual correction systems to meet the needs of industries such as food, daily chemicals, and pharmaceuticals.

Double Feeding Vertical Packaging System Components

The Double Feeding Vertical Packaging System consists of a vibrating feeder, a Z-type elevator, a multi-head combination weigher, and a vertical packaging machine. The vibrating feeder evenly disperses the material, the Z-type elevator optimizes conveying space, and the multi-head weigher uses 12-24 weighing cells to achieve high-precision weighing of ±0.2-1 grams. Finally, the vertical packaging machine completes the entire process of bag making, filling, heat sealing, and cutting.

Vibrator feeder: Provides initial dispersion and quantitative material delivery, preventing material accumulation or blockage and ensuring stable subsequent conveying. The Z Conveyor stably lifts materials vertically from a low level to the multihead weigher inlet. Its space-saving Z-shaped design accommodates diverse factory layouts and features an adjustable tilt angle. The Multihead Weigher utilizes multiple weighing heads to ensure accurate weight for each bag, with an accuracy range of ±0.2-1 gram. The Vertical Form Fill Seal Machine integrates bag film forming, longitudinal and transverse sealing, and bag cutting. The sealing temperature is PID-controlled, and the sealing pressure is adjustable. It supports a variety of materials, including PE, PP, and aluminum foil composite films.

Double Feeding Vertical Packaging System Features

The Double Feeding Vertical Packaging System utilizes a redundant dual-feed design. The primary and secondary feeding channels can be independently activated and deactivated. When the primary channel runs low on material, the secondary channel automatically replenishes, ensuring continuous production and reducing waiting time. The system can process two materials simultaneously, making it suitable for mixed packaging needs. Its vertical structure allows materials to fall vertically, reducing the risk of cross-contamination. The system supports a variety of packaging formats, including granules, powders, and liquids. Advanced multihead weighing algorithms ensure packaging accuracy. The machine can produce more than 60 bags per minute and support 24-hour continuous operation. It is suitable for medium and high-speed production lines, improves packaging efficiency, and meets the needs of large-scale production.

Technical parameters of Double Feeding Vertical Packaging System

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Price of Double Feeding Vertical Packaging System

The price of Double Feeding Vertical Packaging System is closely related to the structural configuration and performance of the equipment. The basic model is equipped with a single servo motor and a simple control system, and the price is relatively low, generally between US$7,000 and US$42,000, which is suitable for small and medium-sized production lines; while the high-end model is equipped with dual servo drives, touch screen PLC and multi-station filling system, and the price is US$21,000 to US$42,000. The system's processing speed, packaging size range and material compatibility (such as film, aluminum foil, etc.) also directly affect the pricing of the equipment.

When choosing a suitable Double Feeding Vertical Packaging System, many aspects need to be considered, including material characteristics, capacity requirements and compatibility. The corresponding feeding mechanism (such as spiral, vibration or belt feeding) should be selected according to the characteristics of powdered, granular or mixed materials. The system's packaging speed and packaging specifications should match actual production capacity requirements. The system should also offer excellent compatibility, supporting a variety of packaging materials (such as composite film and PE bags) and the ability to switch between different sizes.

Double Feeding Vertical Packaging System Process Flow

The Double Feeding Vertical Packaging System process flow is as follows: material feeding - smooth conveying - precise weighing - bag making and filling - finished product output.

Material Feeding: Two different materials are independently conveyed via vibrator feeders. Each feeder is equipped with a precision vibration controller that adjusts the feed speed and flow rate, ensuring uniform and stable material delivery to the Z Conveyor.

Smooth Conveying: The Z-type conveyor utilizes a multi-stage buffer design. By controlling the inclination angle and speed, it effectively reduces the impact of falling materials, ensuring that loose materials such as powders and granules remain intact and smoothly transition to the inlet of the Multihead Weigher.

Precision Weighing: The 14- or 16-head high-precision combination weigher uses high-speed sensors and intelligent algorithms to analyze material weight distribution in real time, calculating the optimal combination within 0.5 seconds, ensuring a weight error of within ±0.5g per package. It also supports simultaneous weighing of two materials.

Bag Forming and Filling: The Vertical Form Fill Seal Machine utilizes a servo-driven system to complete film drawing, bag forming in the former, and longitudinal sealing and heating steps. A dual-channel filling system then precisely injects the weighed material into the bag, followed by transverse sealing and cutting. The packaging speed can reach 60 bags per minute.

Finished Product Output: Finished bags are automatically output via a conveyor belt equipped with metal detection and weight rechecking devices. Defective products are automatically rejected, while qualified products are conveyed to the next process, achieving fully automated processes.

Applications of the Double Feeding Vertical Packaging System

The Double Feeding Vertical Packaging System is used in industries such as food, pharmaceuticals, and daily chemicals. In the food industry, it is suitable for granular/powdered products such as candy, nuts, biscuits, soy milk powder, milk powder, etc., and supports irregular shapes and sticky materials such as sauces and jams; in the pharmaceutical field, it can be used for the simultaneous filling of granules and powders; daily chemicals and small hardware: suitable for processing granular or powdered raw materials that need to be mixed, and can be used to package soap powder, chemical seasonings, plastic components, small hardware, etc., and compatible with a variety of materials such as plastic bags and composite films.

Double Feeding Vertical Packaging System supports different types of packaging bags. The bottom of the self-supporting bag has a horizontal support structure, and the bottom can stand upright, which is suitable for juice, condiments, and daily chemical products. The zipper bag is equipped with a zipper that can be opened and closed repeatedly, which is suitable for packaging materials such as candy and biscuits. Special-shaped bags meet special needs through waist and handle designs, and are often used for packaging laundry detergent, pet food, etc. Four-side seal/three-side seal bags: heat-sealed on all four sides, suitable for materials such as powders and granules that need to be moisture-proof. Pillow bags (back seal bags) have a simple structure and low cost, and are used for fast packaging of food and daily necessities.