Seed Granule Packaging Machine

Seed Granule Packaging Machine typically produce 15 to 60 bags per minute. Common bag types include stand-up pillow bags, open-mouth bags, and zipper bags. Market prices typically range from US$5,000 to US$20,000./p>

Applicable Materials: Seeds, granular materials Packaging Types: Back-seal bags, three-side seal bags, four-side seal bags Normal Speed: 30-60 bags/minute Packaging Film Materials: PE, PP, aluminum foil composite film, etc. Voltage: 220V/380V, 50Hz

What is Seed Granule Packaging Machine?

Seed Granule Packaging Machine is an automated device used to meter, seal, and package seed granules. Because seeds come in a variety of shapes (such as round, oval, and irregular), and their sizes and fluidity vary depending on the type, the packaging machine's metering accuracy and conveying methods are highly demanding. The primary function of this type of equipment is to increase packaging speed, ensure stable yields, reduce labor costs, and improve packaging consistency. Packaging speeds typically reach 15–60 bags per minute, depending on the machine model and seed characteristics.

Common bag types used by Seed Granule Packaging Machines include stand-up pillow bags, open-top bags, and zipper bags. To enhance stability, some models incorporate anti-sticking features and static elimination devices, making them particularly suitable for handling seeds with poor flowability or prone to sticking. The market price of a Seed Granule Packaging Machine typically ranges from US$5,000 to US$20,000. The machine's high capacity allows for large-scale production, making it suitable for agricultural enterprises, seed companies, and grain processing plants.

What are the benefits of a Seed Granule Packaging Machine?

The Seed Granule Packaging Machine offers numerous advantages, including adaptability to multiple varieties, high precision, low breakage, high efficiency, easy production changeover, and durability and cost-effectiveness. These advantages significantly enhance the packaging quality and production competitiveness of seed companies.

Adaptable to a wide range of seed types: Compatible with a wide range of seed types, including vegetables, grains, and flowers, it is suitable for multi-variety and multi-batch production. It can accommodate both coated and uncoated seeds.

Adaptable to particle sizes and shapes: Supports particles with diameters of 0.5–10mm, from small (rapeseed) to large (corn). It smoothly discharges round or irregular particles, preventing clogging.

Adaptable to different flow properties: Vibratory feeding, spiral feeding, or a measuring cup mechanism accommodate materials with varying flow properties, reducing sticking and instability.

High metering accuracy: Utilizing electronic or combined weighing, the machine maintains an error control of ±0.2%–0.5%, ensuring precision for both small and large packaging, complying with agricultural regulations and market demands.

Low breakage rate: The conveying and feeding process is smooth, avoiding excessive friction and impact. This is particularly effective for fragile, easily broken vegetable seeds or coated seeds.

Flexible production changeover: The modular design allows seed changes by simply adjusting parameters or replacing feeding components, shortening changeover time and making it suitable for small and medium-sized enterprises and multi-variety orders.

Strong continuous operation capability: The high degree of automation allows for long-term continuous operation, adapting to large-scale production. It can be integrated with other equipment such as loading, conveying, sealing, coding, and packaging to form a complete automated production line.

Durability and easy maintenance: Made of stainless steel or wear-resistant alloy, it is rust-resistant and corrosion-resistant, with a long service life. Maintenance is simple, minimizing downtime.

Seed Granule Packaging Machine Specifications

Vertical parameters

| Type | SL-320 | SL-450 |

| Bag style | Back seal/3-side seal/4-side seal | Back seal/3-side seal /4-side seal |

| Packing speed | 32-72bags/min or 50-100bags/min | 20-80bags/min |

| Bag length | 30-180mm | 30-180mm |

| Bag width | 20-145mm(need to replace the former) | 20-200mm |

| Power consumption | 1.8kw | 1.8kw |

| Weight | 250kg | 420kg |

| Dimensions | 650*1050*1950mm | 750*750*2100mm |

Multi head parameters

| Model | SL-420 | SL-520 | SL-720 |

| Packaging bag types | Back seal | Back seal | Back seal |

| Packaging speed | 5-30bags/min | 5-50bags/min | 5-50bags/min |

| Power consumption | 220V, 2.2KW | 220VAC/50Hz | 220VAC/50Hz,5KW |

| Dimension | (L)1320*(W)950*(H)1360mm | (L)1150*(W)1795*(H)1650mm | (L)1780*(W)1350*(H)1950mm |

| Bag length | 80-300mm | 80-400mm | 100-400mm |

| Bag width | 80-200mm | 80-250mm | 180-350mm |

| Air consumption | 0.65Mpa | 0.65Mpa | 0.65Mpa |

| Gas consumption | 0.4m3/min | 0.4m3/min | 0.4m3/min |

Types of Seed Granule Packaging Machines

Seed Granule Packaging Machines are mainly divided into several types to meet the production needs of different seed companies.

Vertical packaging machines use roll film to automatically form bags, integrating automatic weighing, filling, and sealing functions. They feature a compact structure, stable operation, and high speed. They are suitable for packaging small bags weighing 2g–5kg, with a single-machine output of 30–80 bags/minute. They are widely used in the production of small packages for grains, fruits, and lawn seeds.

Open-mouth bag packaging machines use pre-made large bags as packaging containers. After manual or mechanical bagging, they automatically complete filling, sewing, or heat-sealing. They offer the advantages of simple operation and secure packaging. They are suitable for large-volume packaging of 10kg–50kg, with an output of 200–600 bags/hour. They are commonly used for large-volume shipments of agricultural and cash crop seeds.

Multi-head weighing packaging machines are often used in conjunction with vertical bag making machines. They utilize electronic multi-head combination weighers for precise weighing and high-speed unloading, ensuring minimal weight error for each bag of seeds. They are particularly suitable for high-value-added products such as vegetable and flower seeds, with outputs of 50–120 bags/minute, balancing efficiency and precision.

Packaging Options for Seed Granule Packaging Machines

This type of seed granule packaging machine supports a variety of packaging options, including pillow bags, three-dimensional bags, zipper bags, vacuum bags, kraft paper bags, and woven bags. The packaging range generally ranges from 10g bags to 50kg bags, offering a wide range of adaptability. Bag materials include plastic composite films (PET/PE, BOPP/CPP), aluminum foil composite films, paper-plastic composite bags, kraft paper bags, and PE woven bags. Users can choose moisture-proof, damage-resistant, and pest-resistant packaging materials to ensure seed storage and transportation quality.

Seed Granule Packaging Machine Price

Seed Granule Packaging Machine prices vary depending on configuration, production capacity, degree of automation, and package weight range. Entry-level semi-automatic packaging machines range from approximately $5,000 to $8,000 and are suitable for small and medium-sized farms. Mid-range automatic packaging machines range from approximately $8,000 to $15,000 and are suitable for large-scale production at medium-sized enterprises. High-end fully automated production lines, which include integrated systems for loading, weighing, bagging, coding, and inspection, cost approximately $15,000 to $20,000 and are suitable for large factories and seed companies.

What materials are suitable for Seed Granule Packaging Machines?

The Seed Granule Packaging Machine is suitable for packaging a variety of seeds and granular agricultural products, primarily including: grain crop seeds (such as rice, wheat, corn, and barley); vegetable seeds (such as tomato, cucumber, carrot, and pepper); flower seeds (various ornamental and horticultural plant seeds); herb seeds (including medicinal and spice plants); tree seeds (used for afforestation and gardening); lawn grass seeds (various landscape and sports field grass seeds); and other specialty seeds such as cotton, rapeseed, sunflower, and other cash crop seeds. Furthermore, this type of machine can also be used to package similarly shaped granular products, such as grains, beans, nuts, feed pellets, and certain chemical granular products, offering a wide range of applications.

Common seed pellets vary in size and characteristics, ranging from brittle to hard, and from uniform to irregular in shape. Large seeds, such as corn, soybeans, and peanuts, typically have diameters between 5 and 12 mm; medium seeds, such as wheat, barley, and peas, have diameters between 2 and 6 mm; small seeds, such as sesame, rapeseed, and pepper, have diameters of approximately 1 to 3 mm; and very small seeds, such as spinach, mustard, and lawn seeds, typically have diameters less than 1 mm.

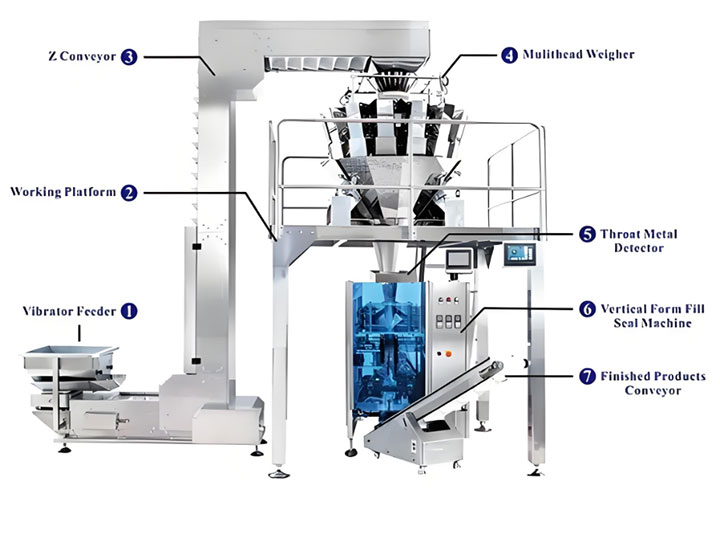

Seed Granule Packaging Machine Working Mechanism

The seed granule packaging machine's working principle involves the following steps: First, an elevator or vibrating feeder evenly feeds the seed granules into a storage hopper. Next, a metering system (such as a screw weighing machine, measuring cup, or electronic combination scale) distributes the seeds in fixed quantities. An automatic bagging system or pre-made bagging device then transfers the seeds into the packaging bags. Finally, a sealing device heat-seals, compacts, and cuts the bags. The entire process, from seed conveying, weighing, filling, to sealing, is fully automated, improving efficiency while ensuring that the seeds are protected from damage and contamination during the packaging process.

How to choose the right seed granule packaging machine?

Selecting the right seed granule packaging machine requires comprehensive consideration of package weight, seed type, material characteristics, and production requirements. Small bags (10g–5kg) are suitable for vertical machines, while large bags (10kg–50kg) are suitable for open-mouth machines. Large, fluid seeds like corn and soybeans can be weighed using a measuring cup or screw type. Small and medium-sized seeds or high-value seeds like vegetable and flower seeds should be weighed using a multi-head weigher to ensure accuracy. For high production volumes, a highly automated and fast machine is recommended, while for small and medium volumes, semi-automatic equipment is recommended.