Powder Packaging Machine

Powder Packaging Machine usually supports the packaging of materials with fine particle size and general fluidity, with output ranging from 10 bags/minute to 80 bags/minute. Depending on the configuration and output, the price is about US$3,000 to US$25,000, depending on the configuration and production capacity. Metering Method: Screw Metering/Weighing Packaging Accuracy: ±1-2% Pack Types Supported: Back Seal/Three-Side Seal/Four-Side Seal/Stand-Up Pouch

What is Powder Packaging Machine?

Powder Packaging Machine typically package materials with fine particle size and medium flowability, such as milk powder, coffee powder, protein powder, flour, and seasonings. Mainstream models include semi-automatic powder packing machines, vertical powder packing machines, and commercial powder packing machines. These machines can package powders ranging from 20 mesh to 400 mesh, with output ranging from 10 to 80 bags/minute. Depending on the configuration and output, prices range from approximately US$3,000 to US$15,000.

Powder packaging machines typically use composite film materials for their bags, offering excellent moisture-proof, oxidation-resistant, and tear-resistant properties, ensuring powder quality and freshness. Common bag types include stand-up pouches, back-seal bags, and four-side-seal bags, allowing you to choose the appropriate bag type for your specific packaging needs. Powder packing machines typically support a variety of capacities, ranging from 10 grams to 5 kilograms.

Advantages of Powder Packaging Machines

Designed for powder materials, this machine can handle powders prone to flying, hygroscopicity, and agglomeration. Equipped with dust removal and vibration devices, it ensures a stable, leak-free packaging process. Compatible with a variety of materials, including PE, PP, and aluminum foil, and with various bag types, including stand-up pouches, three-side seal bags, and four-side seal bags, this machine boasts a high degree of automation, capable of producing 30-60 bags per minute, significantly improving production efficiency and reducing labor costs. Its stainless steel body is corrosion-resistant and easy to clean, and its modular design facilitates maintenance. Its intelligent control system enables quantitative filling and automatic error correction, achieving an accuracy of within ±1%. Its integrated nitrogen filling and vacuum pumping functions extend shelf life, making it suitable for high-end powder products.

Main Parameters of Powder Packaging Machines

| VFFS -320 | VFFS-420 | VFFS-520 | VFFS-720 | |

|---|---|---|---|---|

| Packing Speed | 5-70bags/min | 5-60bags/min | 5-50bags/min | 5-40bags/min |

| Bag Length | 50-200mm | 80-300mm | 100-400mm | 100-450mm |

| Bag Width | 50-150mm | 50-200mm | 100-250mm | 100-350mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | Max.320mm |

| Filling Range | 50-800ml | 150-1200ml | 200-2000ml | 250-4000ml |

| Film Width | Max. 320mm | Max. 420mm | Max. 520mm | Max. 720mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Air Consumption | 0.3m3/min 0.65MPa | 0.3m3/min 0.65MPa | 0.4m3/min 0.65MPa | 0.4m3/min 0.65MPa |

| Voltage | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz |

| Power | 2.0kw | 2.2kw | 4kw | 4.5kw |

| Machine Dimensions | 117*82*129cm | 132*95*136cm | 149*108*149cm | 172*126*182cm |

| Machine Weight | 350kg | 550kg | 750kg | 850kg |

Differences Between Different Types of Powder Packaging Machines

Powder packaging machines can be categorized into various types based on their structure, capacity, and degree of automation. Vertical packaging machines utilize screw metering and are suitable for small-volume packaging. Horizontal packaging machines accommodate a variety of bag types, offering high flexibility. Commercial models can be equipped with optional nitrogen filling or inkjet printers. Semi-automatic models require manual bagging and offer a more cost-effective solution. Multi-lane packaging machines can simultaneously package multiple rows of small-dose powders, improving efficiency.

Vertical Powder Packaging Machines: These screw metering systems are suitable for small to medium-sized bags of powder products. The rotating screw precisely controls the powder delivery rate, ensuring consistent weight per bag and minimizing waste. This system is particularly suitable for fine, free-flowing powders. Combined with back-seal or three-side-seal bagging, this system automates the bag-making, filling, and sealing processes, with a packaging speed of 1,300-5,000 bags/hour and an output of approximately 1,500-3,500 bags/hour.

Horizontal Powder Packaging Machines: These machines are suitable for various packaging types, such as four-side-seal bags, zipper bags, and stand-up pouches. They are typically equipped with weighing or multi-head filling systems for improved accuracy and efficiency. They offer packaging speeds of 20-50 bags per minute and an output of approximately 1,200-3,000 bags per hour. They are suitable for packaging powdered materials such as milk powder and flour, which require high precision.

Commercial Powder Packaging Machines: These machines are designed for large-scale production, offering high speed, high precision, and full automation. Optional automatic loading, dust removal, coding, and nitrogen filling systems are available. Automatic loading improves efficiency, dust removal maintains cleanliness, coding meets traceability requirements, and nitrogen filling extends shelf life. These machines are suitable for powder products susceptible to moisture or oxidation. These machines can operate 24/7, with packaging speeds ranging from 2,800 to 8,000 bags/hour and output exceeding 6,000 bags/hour.

Semi-automatic Powder Packaging Machines: These machines are simple in design, combining manual bagging with automatic metering and sealing, making them ideal for manufacturers with limited budgets or lower production requirements. They offer packaging speeds of 10-20 bags/minute and outputs ranging from approximately 500 to 1,100 bags/hour. They are suitable for packaging a variety of powder materials.

Multi-lane powder packaging machine: This machine is suitable for packaging small-dose powders, such as coffee powder and seasoning powder. It can perform 4-14 simultaneous bag-making and filling operations, significantly increasing throughput per unit time. Each lane can produce 30-50 bags/minute, for a total speed of 5,000-15,000 bags/minute.

Powder Packaging Machine Price Analysis

The model, function, and production capacity of the machine affect the price of a powder packaging machine. When choosing a machine, consider factors such as production capacity, powder properties, and budget. Generally speaking, the prices of common powder packaging machines can be roughly categorized into the following types:

Small Single-shot Packaging Machines: These machines are suitable for small-batch production and are primarily used to package fine powders such as tea and coffee powder. They typically cost between $2,000 and $5,000 and are suitable for small and medium-sized businesses.

Medium-sized automated packaging machines: These machines offer a high level of automation, capable of automatic metering, packaging, and sealing, and are suitable for large-scale production at medium-sized enterprises. Prices typically range from $3,000 to $8,000, varying depending on packaging speed and accuracy.

Large-scale fully automated packaging lines: These machines are typically used for large-scale production and feature high production capacity and a more complex operating system, such as fully automated batching, conveying, and packaging. They are suitable for large enterprises. Prices range from $9,000 to $15,000, or even higher.

Customized high-end packaging machines: If the equipment is customized to meet specific requirements (such as special powder properties or strict hygiene requirements), the price may be higher, typically around $15,000.

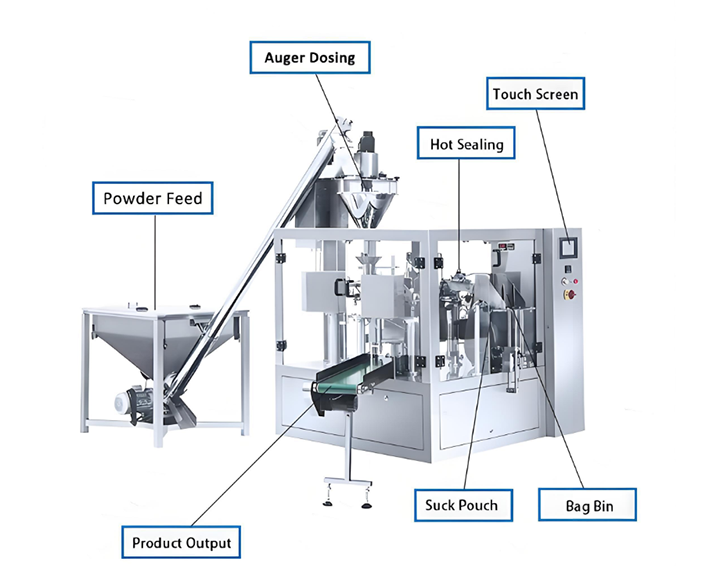

Powder Packaging Machine Structure

The Powder Packaging Machine consists of a feeding system, weighing system, bag filling system, control system, drive system, and conveyor system. The feeding system uses a screw or vibrating mechanism to evenly convey powder material into the packaging bags. The weighing system precisely controls the material weight to ensure consistent quality in each bag. The bagging system forms and seals the bags, while a heat-sealing device ensures a leak-proof seal. The control system, via a PLC or touchscreen, manages the entire packaging process. The drive system provides power, and the conveyor system transports the packaged bags to the next process or distribution area.

Powder Packaging Machine Principle

Powder enters the metering system through a feeder, where it is precisely metered using a screw or load cell. The packaging material is then automatically formed into bags of a preset size by a bag maker. The filled bags are sealed with a heat-sealing element and cut to the desired length by a cutting device. Finally, the finished products are transported via a conveyor belt to the next stage of processing.

Powder Packaging Machine Supplier

Our factory specializes in the design and manufacture of powder packaging machines. We can provide customized solutions based on various powder characteristics, bag shapes, bag lengths and widths, bag materials, production volumes, and equipment functionality. The unique dust-proof design combined with a vibrating compactor effectively solves the problem of powder dispersion during packaging. We also offer customized models for special operating conditions, such as explosion-proof and vacuum-proof, to meet specific customer needs.

Powder Packaging Machine Applications

Powder packaging machines are widely used in the food industry, such as packaging milk powder, coffee powder, and seasonings; in the pharmaceutical industry, for precise packaging of powdered medicines and nutritional supplements; and in the chemical industry, for automated packaging of dry powder chemicals such as pigments and additives. These industries place high demands on packaging speed and tight sealing, and these machines can effectively improve production efficiency and product quality.