Plastic Granule Packaging Machine

Plastic Granule Packaging Machines offer packaging options ranging from 10-50 kg bags or bulk bags. Common packaging options include open-mouth bags, valve bags, automatic bag making, and bulk bags. Prices range from US$2,000 to US$10,000. Equipment Dimensions: 1200 × 800 × 1600 mm Packaging Weight Range: 10-50 kg Packaging Type: Bags Packaging Speed: 400 bags/hour Automation Level: Fully Automatic

What is Plastic Granule Packaging Machine?

Plastic Granule Packaging Machine is used to automatically weigh, bag, and seal plastic granules of various shapes and sizes, such as PP, PE, ABS, and PET, according to a set weight. Granule sizes range from 2-8 mm in diameter and 2-12 mm in length. The machine's packaging range covers 10-50 kg per bag or in bulk bags. Common packaging formats include open-mouth bags, valve bags, automatic bag making, and bulk bags. Sealing methods include heat sealing, sewing, or a combination of these. The machine supports touchscreen settings and recipe management, enabling quick switching between multiple specifications. It also features anti-jamming, anti-static, and dust removal features to accommodate different granule types and flow properties.

This type of Plastic Granule Packaging Machine boasts a packaging speed of 5-15 bags/minute for basic models and up to 40 bags/minute for high-speed models. Its weighing accuracy is typically ±0.1% ±0.2%. Industrial-grade models can operate 24/7, making them suitable for the high-volume automated packaging needs of plastic raw material production, modification, and recycled granulation companies.

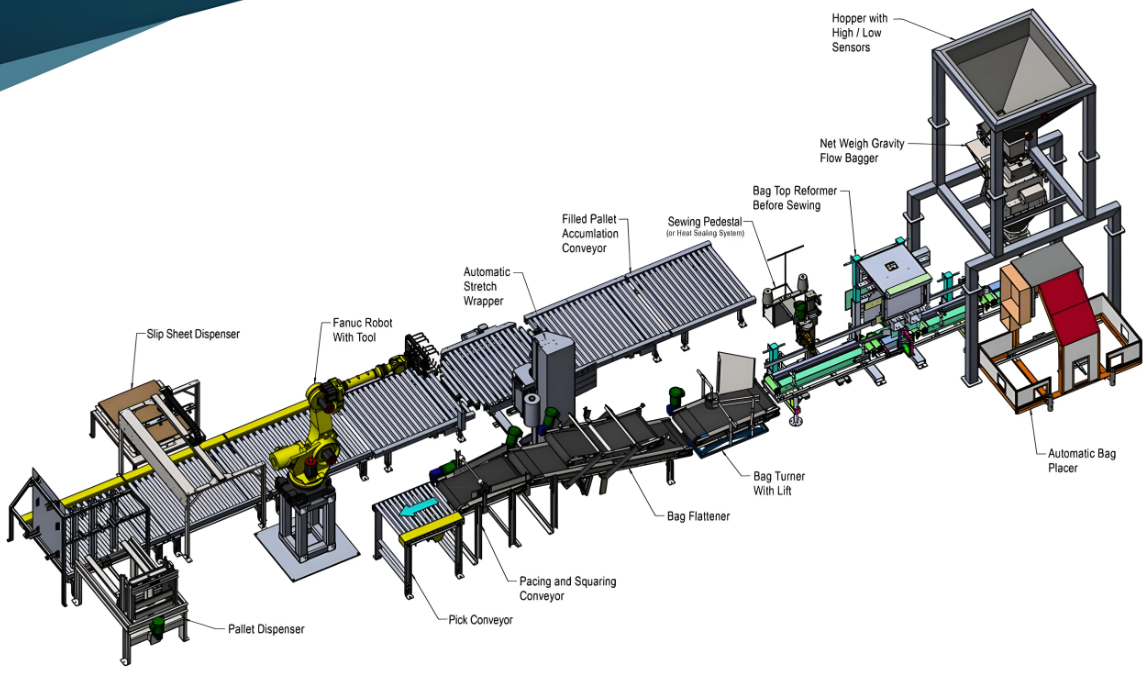

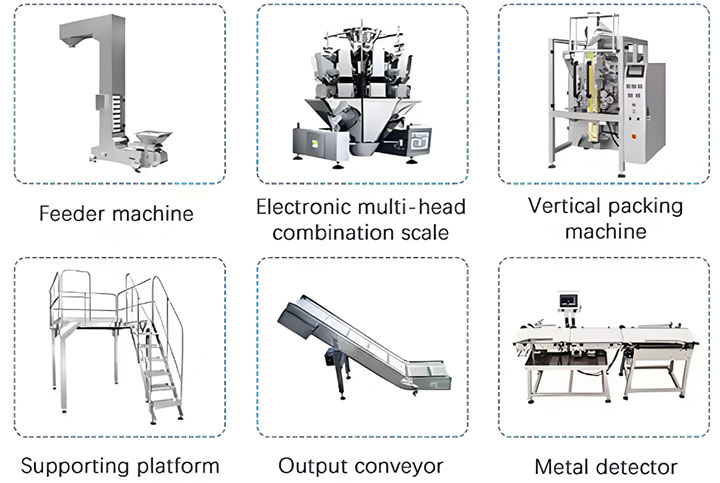

Plastic Granule Packaging Machine Components Introduction

The Plastic Granule Packaging Machine primarily consists of the following core components:

The feeding system primarily consists of a storage silo, a vibrating screen, and a feeding device. The feeding device can be a screw feeder or belt conveyor, ensuring uniform delivery of plastic granules to the weighing stage.

Weighing System: High-precision sensors and electronic scales combine to achieve quantitative weighing with an error control within ±0.1%.

Bag-making and Sealing/Cutting Mechanism: Consisting of a film reel, former, heat-sealing blade, and cutter, the machine integrates bag-making, filling, and sealing operations.

Control System: A PLC or microcomputer control center coordinates the operation of various components, supports parameter setting, and supports fault diagnosis.

Drive: A motor, belt, and chain form the power system, driving the mechanical movement.

Auxiliary components: These include a coder (printing production information), a dust removal device (cleaning particles), and a safety shield.

What are the types of plastic granule packaging machines?

The following five common types of plastic granule packaging machines are available. VFFS and pre-made bag machines are suitable for flexible small and medium-sized production runs, open-mouth bagging and vertical bagging machines are suitable for industrial-scale large-scale production, and multi-head weighing machines are known for their high precision.

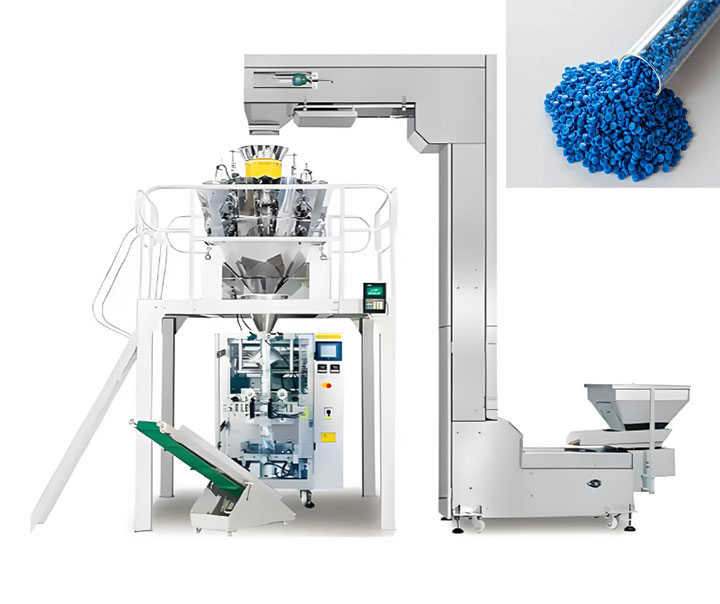

VFFS vertical bag forming, filling, and sealing machines: Highly automated, they use roll film for automatic bag forming, filling, and sealing. They are suitable for small granular materials weighing 1-5 kg (such as plastic granules and sugar). Measuring methods include screws or measuring cups, offering high precision and a production speed of 40-60 bags/minute. They have strong anti-interference capabilities and are suitable for continuous production, requiring regular calibration. Contact parts are made of stainless steel or food-grade plastic, resulting in a compact structure, long-lasting wear parts, and easy maintenance. A built-in dust collector controls dust, allowing for flexible customization.

Pre-made bag quantitative packaging machine: Highly automated, with a robotic arm performing bag removal, opening, filling, and sealing, it can accommodate a variety of bag types. Measuring is done by gravimetric or volumetric methods, offering stable accuracy and a speed of approximately 20-40 bags/minute. It exhibits excellent anti-interference performance, but careful bag opening alignment is required. Contact parts are made of stainless steel or Teflon to reduce sticking. While relatively large, the equipment offers excellent dust control and is suitable for medium- and large-scale, high-value-added products (such as pet food and plastic pellets).

Open-mouth bagging system: Moderately automated, it is used for large-volume industrial packaging of 15-50kg and requires manual assistance. It uses gravimetric measurement, but accuracy is affected by material flowability and has a relatively low speed (10-20 bags/minute). It offers fair anti-interference performance, and contact parts are made of carbon steel or stainless steel, resulting in a sturdy structure suitable for batch production of a single product (such as plastic pellets).

Vertical Big Bag Packaging Machine: Highly automated, capable of handling medium-sized bags under 25kg, integrating bag making, filling, and sealing. It combines weighing and volumetric methods, achieving a speed of approximately 15-30 bags/minute. It offers strong anti-interference capabilities, stainless steel or chrome-plated contact parts, and a modular design for easy maintenance. Dust control is achieved through a closed-loop design, making it suitable for diverse medium-sized operations.

Multi-Head Weighing Granule Packaging Machine: Highly automated, featuring multiple weighing heads working together to achieve an accuracy of ±0.1% and a speed of 80-120 bags/minute. It offers excellent anti-interference capabilities, with software algorithms compensating for errors. Contact parts are made of stainless steel or ceramic, resulting in a precise structure and high maintenance costs. It offers strong customization capabilities and is suitable for high-speed, high-precision production (e.g., food and high-end plastic granules).

Plastic Granule Packaging Machine Specifications

| Model(Roll film width) | FP-320 | FP-420 | FP-540 | FP-730 | FP-920 | FP-1100 | FP-1500 |

| Bag Length(mm) | 80-180 | 80-300 | 80-400 | 100-400 | 150~600 | 200~900 | 200-1000 |

| Bag Width(mm) | 45-150 | 50-200 | 80-250 | 180-350 | 150~450 | 150~530 | 200~730 |

| Max Width of Roll(mm) | 320 | 420 | 520 | 720 | 920 | 1100 | 1500 |

| Packing Speed(bags/min) | 20-55 | 20-80 | 20-100 | 20-100 | 10~90 | 10-80 | 5-50 |

| Air Consumption(Mpa) | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 |

| Gas Consumption(m3/min) | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 |

| Power Voltage (v) | 220v/380v | 220V/380v | 220v/380v | 220v/380v | 220v/380v | 220v/380v | 220v/380v |

| Power (kw) | 3kw | 2.2KW | 4kw | 5kw | 5kw | 6kw | 6kw |

| Weight(kg) | 350 | 540 | 600 | 900 | 1000 | 1100 | 1200 |

Plastic Granule Packaging Machine Price

This small, basic plastic granule packaging machine is typically constructed of ordinary steel or engineering plastics and has a relatively simple structure. It has a low level of automation, often operating semi-automatically, requiring manual assistance for some steps. Suitable for small-scale production or laboratory use, production scales typically fall within a few hundred kilograms per hour. Package weights typically range from 1 to 25 kilograms, with relatively simple functions, completing only basic packaging processes. Prices typically range from $2,000 to $5,000.

Medium-sized, multifunctional Plastic Granule Packaging Machines are constructed from high-quality stainless steel for durability and easy cleaning. They offer a high degree of automation, enabling automated metering, filling, and sealing operations. They meet the production needs of general enterprises, with production scales of 1 to 3 tons per hour. Package weights range from 5 to 50 kilograms, offering flexible adjustments, more accurate metering, and a variety of packaging options. Prices range from approximately $8,000 to $15,000.

Large, fully automatic, high-speed Plastic Granule Packaging Machines are constructed from high-strength alloys for durability. They are highly automated, completing the entire process from pellet conveying and metering to packaged product delivery. Suitable for large-scale industrial production, they can reach over 3 tons per hour. The packaging weight range is 10-100 kg or even wider, and it features high efficiency and stability, often costing over $20,000.

Plastic Granule Packaging Machine Applications

Main Application Areas

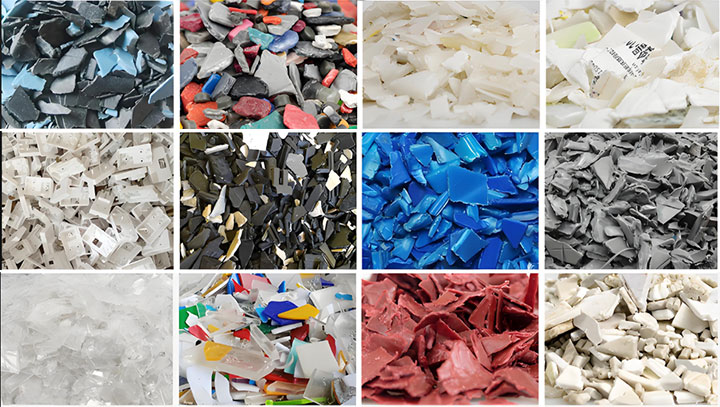

Plastic Granule Packaging Machines are widely used in the plastic raw material industry, chemical industry, recycling industry, and specialized food/agricultural product granule packaging. They can be used to quantitatively package plastic granules such as polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), ABS, and PET, as well as fertilizer granules, modified plastics, and additive granules. They are commonly used in petrochemical plants and plastic granulation plants for the final product shipment. They are also suitable for the bagged transportation and sales of recycled plastic granules. For food or agricultural products such as coffee beans, sugar granules, and grains, they require food-grade contact components to meet hygiene requirements.

Applicable Packaging Types

The Plastic Granule Packaging Machine is suitable for a variety of packaging types, including bags, with common sizes ranging from 10kg to 50kg per bag, such as valve bags, woven bags, and PE bags; ton bags for large-volume bulk granules, with sizes ranging from 500kg to 1500kg per bag; and small packages, such as 5kg to 10kg bags, suitable for retail or sample distribution.

What are the uses of plastic granule?

Plastic granule comes in a variety of types and properties, and is widely used in packaging, building materials, automotive, home appliances, optics, fibers, and other fields, meeting diverse requirements such as flexibility, heat resistance, abrasion resistance, and transparency.

Polyethylene (PE): Low-density polyethylene (LDPE) is soft, transparent, and chemically resistant, and is commonly used in films and packaging bags. High-density polyethylene (HDPE) offers excellent rigidity, heat resistance, and chemical resistance, and is used in containers, pipes, and toys.

Polypropylene (PP): Polypropylene has average transparency, good heat resistance, and strong chemical stability. It is widely used in automotive parts, daily necessities, fibers, and food packaging.

Polyvinyl chloride (PVC): Rigid PVC is used in construction pipes and profiles, while soft PVC is used in wire jacketing and artificial leather. PVC offers strong chemical resistance and flame retardancy, but is also brittle.

Polystyrene (PS): General-purpose polystyrene (GPPS) is a transparent, brittle material used in stationery and packaging. High-impact polystyrene (HIPS) offers excellent impact resistance and is often used in appliance casings.

Polyamide (PA): Polyamides such as nylon 6 and nylon 66 offer high mechanical strength, wear resistance, and high-temperature resistance, and are commonly used in gears, bearings, and automotive parts.

Polyethylene terephthalate (PET): PET offers excellent transparency, chemical resistance, and heat resistance, and is primarily used in beverage bottles, food packaging, and fibers.

Polycarbonate (PC): Polycarbonate offers high transparency, strength, and heat resistance, and is commonly used in optical lenses, electronic components, and automotive parts.

Other engineering plastics: including POM (polyoxymethylene), PBT, ABS, and TPU, offer high-temperature resistance, high strength, and special features such as wear resistance, elasticity, and flame retardancy.

Plastic Granule Packaging Machine Production Demonstration