Pharmaceutical Granule Packaging Machine

Pharmaceutical Granule Packaging Machine integrate automated metering, bag making, filling, sealing, and coding functions, suitable for various bag sizes, including three-side seal, four-side seal, and back-seal. Output varies depending on the machine model, typically ranging from 30 to 200 bags per minute, with prices ranging from $7,000 to $10,000. Production Capacity: 10-50 bags/minute Packaging Specifications: 1-100g/bag Accuracy: ±1% Applicable Packaging Materials: Composite Film/Aluminum Foil

What is Pharmaceutical Granule Packaging Machine?

Pharmaceutical Granule Packaging Machine is suitable for granular pharmaceuticals with good flowability, reducing uneven feeding caused by material clumping. For hygroscopic pharmaceuticals, it can be equipped with moisture-proof feeding and packaging structures to prevent deterioration. Its metering accuracy typically reaches ±1% to ±3%, and it can package common sizes from 0.1g to 50g, with a packaging speed of 30 to 120 bags per minute.

The packaging bags are typically made of composite films ,such as PET/AL/PE and NY/PE, to ensure barrier properties, tear resistance, and heat-sealability. Modern pharmaceutical granule packaging machines integrate automated metering, bag making, filling, sealing, and coding functions, suitable for various bag sizes, including three-side seal, four-side seal, and back-seal. Output varies depending on the machine model, typically ranging from 30 to 200 bags per minute, with prices ranging from $7,000 to $10,000, depending on the level of automation and production capacity.

Features of Pharmaceutical Granule Packaging Machines

Pharmaceutical Granule Packaging Machines feature high-precision metering that meets pharmacopoeial standards; strong material adaptability; aseptic design; convenient intelligent control; dynamic metering to ensure accurate dosage; and flexible packaging formats, accommodating various bag types, including back-seal, as well as customized requirements.

The equipment uses a servo motor or screw metering system, combined with an internal weighing module or measuring cup system to achieve dynamic metering, ensuring that the particle distribution error is ≤±1%, the dosage of each package of drug particles is accurate, and it meets the pharmacopoeia standards and drug consistency requirements; in terms of material compatibility, it can handle fragile, sticky and highly fluid particles without damage or clogging; it also has a sterile design, with contact parts made of 304 stainless steel and equipped with a laminar flow hood, which is GMP-certified and can effectively reduce the risk of contamination; the control level is equipped with a PLC + touch screen human-machine interface, supporting parameter storage, fault alarm and data traceability; in terms of packaging function, it can support back-seal, three-side seal and four-side seal bag types, and can customize tear notches, zippers and other functions.

Pharmaceutical Granule Packaging Machine Technical Parameters

| Model(Roll film width) | FP-320 | FP-420 | FP-540 | FP-730 | FP-920 | FP-1100 | FP-1500 |

| Bag Length(mm) | 80-180 | 80-300 | 80-400 | 100-400 | 150~600 | 200~900 | 200-1000 |

| Bag Width(mm) | 45-150 | 50-200 | 80-250 | 180-350 | 150~450 | 150~530 | 200~730 |

| Max Width of Roll(mm) | 320 | 420 | 520 | 720 | 920 | 1100 | 1500 |

| Packing Speed(bags/min) | 20-55 | 20-80 | 20-100 | 20-100 | 10~90 | 10-80 | 5-50 |

| Air Consumption(Mpa) | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 |

| Gas Consumption(m3/min) | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 |

| Power Voltage (v) | 220v/380v | 220V/380v | 220v/380v | 220v/380v | 220v/380v | 220v/380v | 220v/380v |

| Power (kw) | 3kw | 2.2KW | 4kw | 5kw | 5kw | 6kw | 6kw |

| Weight(kg) | 350 | 540 | 600 | 900 | 1000 | 1100 | 1200 |

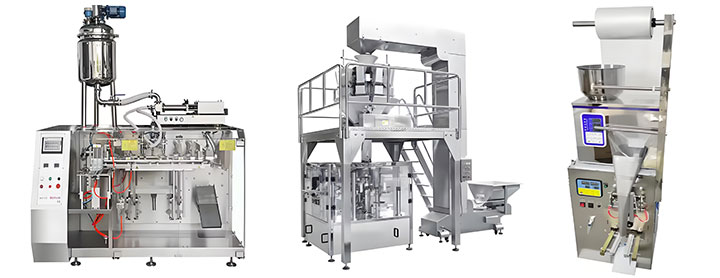

Pharmaceutical Granule Packaging Machine Equipment Types

Pharmaceutical Granule Packaging Machines are available in various types: single-lane for small and medium-sized production; multi-lane for high-speed, high-efficiency production of large batches; vertical models save space and offer a variety of bag types; horizontal models are suitable for large volumes; multi-head weighing systems offer high weighing accuracy; and continuous bagging models reduce film waste and accommodate special packaging needs.

The Single-Lane Pharmaceutical Granule Packaging Machine is suitable for small- to medium-sized production operations, featuring a simple structure and easy operation, with a typical packaging speed of 30-60 bags/minute. It is primarily used for packaging small granular pharmaceuticals ranging from 1g to 100g, such as granules and Chinese herbal medicine slices.

The Multi-Lane High-Speed Pharmaceutical Granule Packaging Machine utilizes multi-lane synchronous filling technology, capable of packaging 1-10g per lane at speeds of 100-300 bags/minute, significantly improving production efficiency. It is suitable for packaging large quantities of single-variety granules, such as vitamin granules and probiotics.

The Vertical Pharmaceutical Granule Packaging Machine utilizes an integrated roll-film design, automatically completing bag making, filling, and sealing, saving space. It is suitable for small- to medium-sized packages (1g to 500g). It offers a variety of packaging options, including back-seal, three-side seal, and four-side seal. It is widely used for automated packaging of pharmaceuticals such as granules, powders, and pills.

The Horizontal Pharmaceutical Granule Packaging Machine is suitable for packaging large-volume granules ranging from 500g to 1kg, such as traditional Chinese medicine granules and health foods. Its stable bag shape makes it suitable for products requiring a tight seal.

The Multi-Head Weighing Pharmaceutical Granule Packaging Machine system has a capacity range from 20g to 2000g. This machine utilizes multiple load cells operating in tandem to achieve weighing accuracy within ±0.5g, making it suitable for granules prone to clumping or poor flowability. It is commonly used for packaging high-end pharmaceuticals and high-value-added health products such as freeze-dried granules and micropellets.

The Pre-made Pouch Pharmaceutical Granule Packaging Machine automates the bagging, filling, and sealing of pre-made bags, minimizing film waste. It is suitable for high-value pharmaceuticals or specialized packaging needs such as aluminum foil bags and anti-static bags. It has a packaging capacity range of 0.5g to 15g and offers flexible packaging options, accommodating bag types such as stand-up pouches and zipper bags.

Pharmaceutical Granule Packaging Machine Applications

Pharmaceutical Granule Packaging Machines are widely used in pharmaceutical companies, hospital preparation rooms, Chinese herbal medicine manufacturers, and health product factories. They are suitable not only for packaging Chinese herbal granules, granules, and Western medicine granules, but also for packaging similar granular health supplements, nutritional powders, probiotic granules, coffee granules, and instant drink granules. For packaging vaccine-adjuvant products, cold granules, anti-inflammatory granules, and children's medicines, the packaging machine effectively ensures drug safety and consistent efficacy through precise dosage control and anti-contamination design.

Pharmaceutical Granule Packaging Machine Price

The price of a pharmaceutical granule packaging machine varies depending on the model, features, level of automation, brand, and production capacity. Basic single-lane small granule packaging machines typically cost between $8,000 and $12,000, with a typical packaging speed of 20-40 bags/minute, making them suitable for small batches or laboratory use. Mid-sized fully automatic packaging machines equipped with PLC controls and multi-function modules cost approximately $15,000-25,000. These machines can support moderate outputs of 40-80 bags/minute and are suitable for medium-sized pharmaceutical plants or routine production needs. High-end, high-speed multi-lane granule packaging machines, such as those designed for large-scale pharmaceutical companies or export orders, can cost as much as $35,000-60,000, capable of high outputs of 200-500 bags/minute. Adding special features such as vacuum dust removal, automatic detection and rejection systems, and automatic roll changing systems will increase the overall price accordingly. Therefore, users should consider their production capacity and functional requirements when purchasing.

Functions of the Pharmaceutical Granule Packaging Machine

The Pharmaceutical Granule Packaging Machine automatically forms and fills bags, ensuring even distribution of granules. It supports multiple specifications and allows for quick packaging changes. It features multi-stage sealing to ensure quality assurance. It also features integrated coding for real-time information printing, integrated inspection and rejection of defective products, and an energy-saving mode to reduce wear and tear.

Automatic Bag Forming and Filling: Automatic film roll formation, with vacuum nozzles or vibrating plates assisting in unloading, ensures even distribution of pharmaceutical granules.

Multi-Specification Compatibility: The modular design allows for infinitely adjustable bag lengths from 80-220mm and bag widths from 30-140mm, enabling quick switching between packaging sizes of 15g small granules or 500g traditional Chinese medicine granules.

Batch Number Printing: An integrated inkjet or laser printer allows for real-time printing of the production date, expiration date, and QR code.

Integrated Inspection: A checkweigher and metal detector eliminate defective products, ensuring packaging integrity.

Multi-Stage Sealing: Heat-sealing combined with cold-pressing technology prevents air leaks and seal cracking, and is suitable for high-temperature and humid environments, extending the shelf life of pharmaceuticals. Energy-saving mode: Low power consumption design automatically reduces speed during standby mode, reducing energy consumption and wear, thereby lowering operating costs.

Pharmaceutical Granule Packaging Machine Bag Sample