Multi-Lane Granule Packaging Machine

The Multi-Lane Granule Packaging Machine is suitable for a variety of granular materials and features automatic metering and sealing. Prices start at $8,000. Packaging Speed: ≤120 bags/minute Applicable Materials: Granules/Tablets/Capsules Bag Size: 50-200mm (Length) x 30-100mm (Width) Measuring Method: Servo Volumetric Power Supply: 4kW/380V

What is Multi-Lane Granule Packaging Machine?

Multi-Lane Granule Packaging Machine can package materials such as coffee granules, milk tea granules, and pharmaceutical granules. It can package various bag shapes, including flat bags, serrated bags, and curved bags, depending on your needs. The Multi-Lane Granule Packaging Machine has a variety of lane options: 4, 6, 8, 10, or 12 lanes. The greater the number of lanes, the faster the packaging speed and the higher the output. The packaging speed ranges from 30 to 80 bags/minute.

How does a Multi-Lane Granule Packaging Machine work?

The Multi-Lane Granule Packaging Machine utilizes multi-head synchronous metering and filling technology. A vibrating feeder evenly distributes granular materials into multiple independent metering hoppers. Each lane simultaneously completes the bag-making, metering, filling, sealing, and slitting processes. Its workflow integrates photoelectric detection and servo control to achieve film roll positioning, precise bag length control, and continuous horizontal sealing. Finally, multiple lanes of finished products are simultaneously discharged through separate delivery devices.

What are the advantages of the Multi-Lane Granule Packaging Machine?

The core advantage of the Multi-Lane Granule Packaging Machine lies in its exceptional efficiency and production capacity. Its multi-lane design, with multiple lanes (typically 4-16) for simultaneous unloading and bag-making, allows it to simultaneously complete multiple production lines, achieving several times the capacity of single-head equipment and significantly reducing unit time costs, making it suitable for large-scale production. Furthermore, it offers excellent economical performance, replacing multiple single-head machines, saving space, purchase, and maintenance costs, resulting in a high return on investment. Integrated high-precision servo control and weighing technology ensure consistent weight across each lane, reducing material waste. Its modular design facilitates rapid changeovers and adapts flexibly to diverse granular packaging needs.

Multi-Lane Granule Packaging Machine Technical Specifications

| Model |

SF320 |

SF620 |

SF720 |

SF820 |

| Track numble | 4-8 track | 4-12 track | 4-12 track | 4-12 track |

| Filling method | volumetric cup filling | |||

| Capacity | 30-45 cycle/min | |||

| Stick size |

L:50-180mm W:17-35mm |

L:50-180mm W:17-65mm |

L:50-180mm W:35-70mm |

L:50-180mm W:35-70mm |

| Film roll size | Max 360mm | Max 650mm | Max 750mm | Max 850mm |

| Sealing type | Back sealing/stick bag/irregular shape | |||

| Power |

3.5KW |

4.5KW |

5.5KW | 6.5KW |

| Air Comsuption |

0.8MPA0.8m³ |

0.8MPA0.8m³ |

0.8MPA0.8m³ |

0.8MPA0.8m³ |

Multi-Lane Granule Packaging Machine Purchase

Multi-Lane Granule Packaging Machine prices vary significantly, primarily influenced by the number of lanes, automation level, and brand. Packaging speed, output, and functionality vary significantly with configuration.

Entry-level or economical domestic equipment typically features a 4-6 lane design, with a packaging speed of approximately 30-60 bags/minute and a daily output of 10,000-20,000 bags in an 8-hour period. These machines primarily provide basic granule filling and sealing functions, supporting only simple manual operations. They are suitable for small workshops or low-capacity operations, and cost approximately $10,000 to $20,000.

Mid-range machines with mainstream configurations typically have 8-12 lanes, with speeds increased to 80-150 bags/minute, enabling daily outputs of 40,000-70,000 bags. These machines also feature new features such as automatic weighing (accuracy ±0.5g), online coding (production date/batch number), and low-material alarms, significantly increasing their automation level and making them suitable for large-scale production for small and medium-sized enterprises. Prices typically range from $20,000 to $50,000.

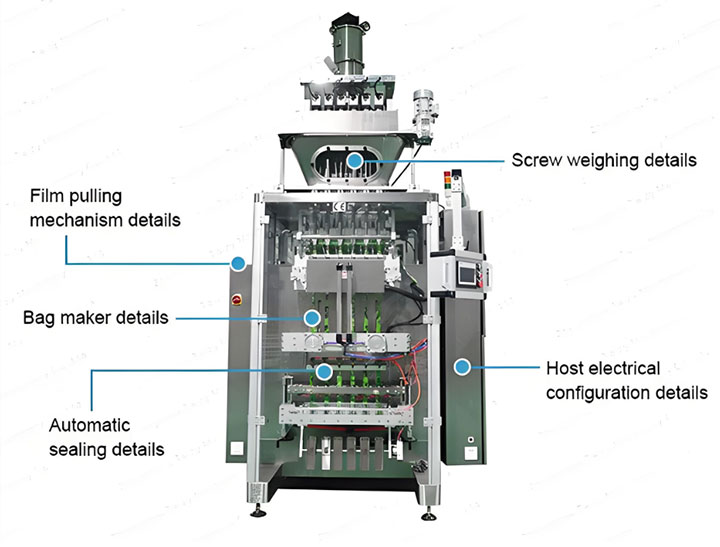

Multi-Lane Granule Packaging Machine Structure

The Multi-Lane Granule Packaging Machine's structure includes: a film pulling mechanism for pulling the packaging film; a bag maker for bag shaping; automatic sealing for bag sealing; a screw weighing mechanism for precise material measurement; and a host electrical configuration providing electrical control and support for machine operation. These components work together to complete the granule packaging operation.

Multi-Lane Granule Packaging Machine Packaging Types

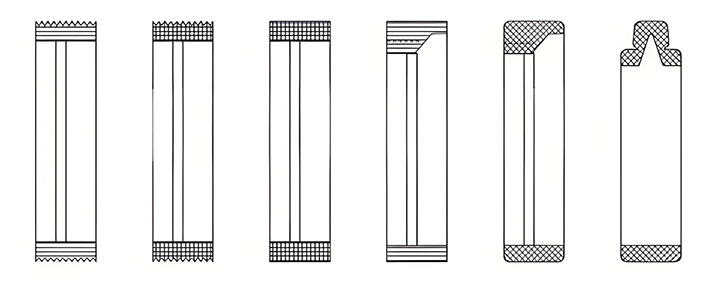

The Multi-Lane Granule Packaging Machine can produce a variety of common bag types, including flat bags, serrated bags, and shaped bags. Film rolls are typically made from composite films such as PET/AL/PE, PET/PE, NY/AL/PE, NY/PE, or OPP/PE. Heat or cold sealing options are available. Heat sealing offers durability, excellent sealing, wide applicability, and low cost. Cold sealing prevents heat damage, perfectly protecting heat-sensitive products, and provides a soft, easy-to-tear seal. Bag length and width vary depending on the machine model, generally ranging from 40-180mm in length and 12-120mm in width. Packaging capacity typically ranges from 1-150g, depending on the machine model and material characteristics.

Multi-Lane Granule Packaging Machine Bag Type Display

Multi-Lane Granule Packaging Machine Applications