Fully automatic sealing packaging machine

The sealing system of the fully automatic sealing packaging machine supports 120–230℃ PID constant temperature control, and the sealing width is generally 4–12mm, ensuring a firm, beautiful and leak-proof seal. Depending on the different configurations and functions (such as coding, inflation, anti-counterfeiting identification, etc.), the price of the whole machine is generally between USD $2,800–$12,000.

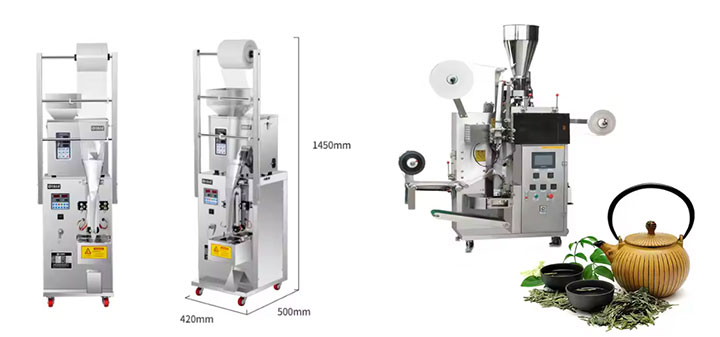

Sealing width: 10–15mm Sealing speed: 10–30 times/minute Power configuration: 220V/50Hz Power range: 1.5–2.0kW Temperature control accuracy: ±2°C Applicable bag type: plastic, composite bag Control system: intelligent temperature control

What is a fully automatic sealing packaging machine?

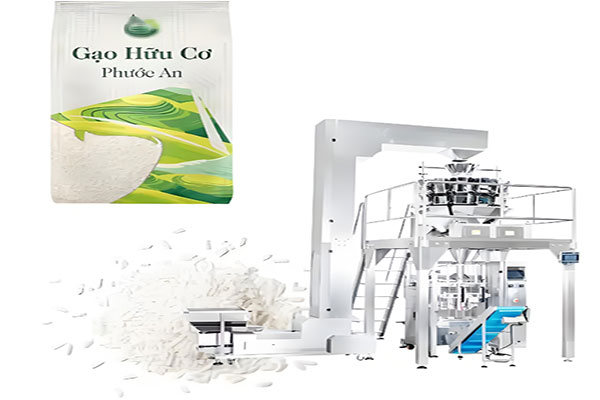

Fully automatic sealing packaging machine has become an indispensable key equipment in modern production lines due to its fast, accurate and stable characteristics. This type of equipment integrates mechanical transmission system, intelligent PLC control, constant temperature heat sealing technology and visual inspection module to realize the full process automation from automatic material metering, precise forming of packaging bags to high-quality sealing and finished product output. Some high-speed models can produce 3,000–7,200 packages per hour, effectively meeting the needs of large-scale continuous production. The sealing system supports 120–230°C PID constant temperature control, and the sealing width is generally 4–12mm, ensuring a firm, beautiful seal without leaking packages. Depending on the different configurations and functions (such as coding, inflation, anti-counterfeiting identification, etc.), the price of the whole machine is generally between USD $2,800–$12,000, providing a reliable guarantee for enterprises to improve packaging efficiency and product consistency.

The technology of the Fully automatic sealing packaging machine is based on hot melt sealing and intelligent control. When plastic film or aluminum foil bags are used as packaging materials, the equipment heats the upper and lower heating blocks to a preset temperature (usually 150-200°C) through electric heating elements, and uses the sealing belt to transfer heat to the bag mouth to melt and bond the film. The cooling system then intervenes, and the mesh pattern or production date is pressed out through the knurling wheel or the printing wheel, and finally the sealing is completed.

What are the characteristics of the Fully automatic sealing packaging machine?

Fully automatic sealing packaging machine has multiple advantages such as reasonable structural design, convenient operation and convenient operation. Its core lies in the highly automated design, which can automatically complete the processes of feeding, metering, filling, sealing, cutting, etc., and significantly improve production efficiency. In terms of packaging length, the equipment supports adjustable packaging length from 50mm to 600mm, which is suitable for packaging needs of various specifications of products from small packaging (such as food granules, drug bags) to medium and large packaging (such as daily chemical bags, industrial supplies, etc.). At the same time, the equipment has stable performance, adopts high-quality electrical components and intelligent PLC control system to ensure long-term continuous operation without trouble. In addition, from an economic point of view, the fully automatic sealing packaging machine reduces labor input, reduces labor costs, and effectively controls material waste.

Fully automatic sealing packaging machine type

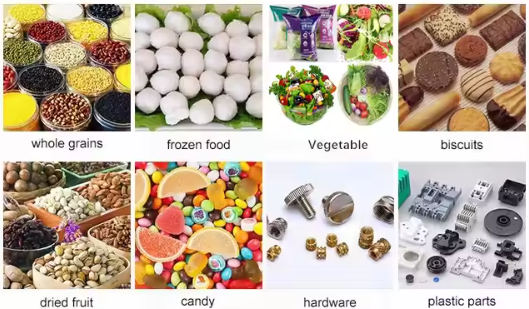

Fully automatic sealing packaging machine is classified according to different material types, mainly divided into granule, powder, liquid, paste and other packaging machines

Liquid Fully automatic sealing packaging machine is suitable for packaging various low to medium viscosity liquid products such as juice, seasoning, mineral water, soy sauce, vinegar, etc. The equipment usually adopts piston pump or magnetic pump metering system, combined with automatic liquid supply and liquid level sensing device to ensure stable filling without dripping. The machine body and liquid contact parts are made of food grade 304 or 316L stainless steel to ensure hygiene and safety; the sealing structure supports three-side sealing, back sealing and other forms. In terms of technical parameters, the packaging speed is 20-50 bags/minute, the bag length is 50-250mm, the bag width is 40-150mm, the metering range is 50ml-1000ml, the metering accuracy is ±1%, the equipment power is about 2.2kW, the power supply is AC220V, the air source needs 0.6MPa, 0.25m³/min, and it is widely used in automatic packaging of beverages and seasoning liquids.

Granules Fully automatic sealing packaging machine is mainly suitable for fully automatic packaging of candy, nuts, biscuits, pharmaceutical granules and other materials. Its structure usually adopts measuring cup measurement or multi-head electronic combination scale, with vibration feeder to ensure accurate and uniform material delivery; the sealing method is mainly heat sealing, supporting back sealing, three-side sealing or four-side sealing. The machine body is mostly equipped with auxiliary devices such as formers and automatic feeders to adapt to different particle forms. Typical technical parameters are: packaging speed 30-80 bags/minute, bag length 50-300mm, bag width 40-200mm, metering accuracy ±12%, power about 2.5kW, using AC220V power supply, air source demand is 0.6MPa, 0.3m³/min, suitable for high-speed automatic production of granular products.

Powder Fully automatic sealing packaging machine is suitable for automatic packaging of fine powder materials such as coffee powder, milk powder, flour, seasoning powder, Chinese medicine powder, etc. The whole machine adopts a screw metering system, equipped with a servo motor drive, with high metering accuracy, and combined with a dust removal design to prevent dust flying and sealing pollution. The packaging structure supports back sealing, corner bag and other forms. The whole machine is made of stainless steel, which is easy to clean and meets food grade standards. The main technical parameters include: packaging speed 20-60 bags/minute, bag length 60-350mm, bag width 50-220mm, metering accuracy ±1%, rated power about 3.0kW, power supply AC380V/50Hz, air source 0.6MPa, 0.4m³/min, suitable for packaging of various powder products with good fluidity.

Paste Fully automatic sealing packaging machine is specially designed for medium and high viscosity products such as sauces, honey, shampoo, toothpaste, and cosmetic paste materials. The machine adopts piston pump or peristaltic pump quantitative filling system, accurate metering, and supports heating and heat preservation, automatic stirring and other functions to prevent material solidification or stratification. The sealing is stable and beautiful, suitable for various bag types such as three-side sealing, back sealing, etc. The main parameters include packaging speed 15-40 bags/minute, bag length 60-300mm, bag width 50-180mm, metering range 30ml-500ml, accuracy control within ±1.5%, power supply AC380V/50Hz, power about 3.5kW, and need to be equipped with 0.6MPa, 0.35m³/min air source, suitable for precise packaging of high-viscosity products.

Common parameters of Fully automatic sealing packaging machine

The parameters of Fully automatic sealing packaging machine vary depending on the model and application scenario. The following are common parameters:

| MRZK 100 Series | MRZK12S-100 | MRZK14-100F | MRZK14-130E | MRZK12-160B |

| Bag width |

50 – 100mm 2 – 3.9in |

55 – 100mm 2.2 – 3.9in |

60 – 130mm 2.4 – 5.1in |

80 – 160mm 3.1 – 6.3in |

| Bag length |

≤ 180mm ≤ 7.1in |

≤ 220mm ≤ 8.7in |

60 – 220mm 2.4 – 8.7in |

≤ 320mm ≤ 12.6in |

| Filling Volume | 5 – 50g | 5 – 50g | 5 – 50g | 10 – 100g |

| Capacity | ≤ 150bags/min | ≤ 100bags/min | ≤ 85bags/min | ≤ 80bags/min |

| Package Accuracy | Error≤ 1% | Error≤ 1% | Error≤ 1% | Error≤ 1% |

| MRZK 200/300 Series | MRZK10-200A | MRZK10-240A | MRZK10-260 | MRZK10-280 | MRZK10-300 |

| Bag width |

90 – 200mm 3.5 – 7.9in |

130 – 240mm 5.1 – 9.4in |

140 – 260mm 5.1 – 10.2in |

170 – 280mm 6.7 – 11in |

190 – 300mm 7.5 – 11.8in |

| Bag length |

≤ 320mm 12.6in |

≤ 320mm 12.6in |

≤ 360mm 14.1in |

≤ 450mm ≤ 17.8in |

≤ 450mm ≤ 17.8in |

| Filling Volume | 10 – 1000g | 10 – 1000g | 10 – 1000g | 10 – 1000g | 20 – 1000g |

| Capacity | ≤ 50bags/min | ≤ 50bags/min | ≤ 40bags/min | ≤ 35bags/min | ≤ 35bags/min |

| Package Accuracy | Error≤ 1% | Error≤ 1% | Error≤ 1% | Error≤ 1% | Error≤ 1% |

| MRZK Nitrogen Series | MRZK12-161 | MRZK12-163A | MRZK10-241 |

| Bag width |

80 – 130mm 3 – 5.1in |

55 – 100mm 2.2 – 3.9in |

90 – 160mm 3.5 – 6.3in |

| Bag length |

≤ 190mm ≤ 7.5in |

≤ 270mm ≤ 10.6in |

≤ 240mm ≤ 9.4in |

| Thickness |

≤ 50mm ≤ 2in |

≤ 50mm ≤ 2in |

≤ 50mm ≤ 2in |

| Capacity | ≤ 50bags/min | ≤ 50bags/min | ≤ 50bags/min |

| Package Accuracy | Error≤ 1% | Error≤ 1% | Error≤ 1% |

Market price of Fully automatic sealing packaging machine

The price of Fully automatic sealing packaging machine varies significantly due to function and production capacity:

Small household model: Price 25-150 US dollars, designed for home kitchens or small businesses. Its design structure has a simple vacuum pump, a small sealing strip and an operation panel. The vacuum pump is responsible for extracting air, the sealing strip can quickly seal the packaging bag, and the operation panel is simple and easy to understand. Although the output is limited, it can meet the daily preservation of small amounts of food.

Commercial medium-sized model: Priced at $800-2,500, it is aimed at restaurant chains, bakery workshops and other scenarios. It has a dual heating sealing device, an adjustable bag holder and an intelligent control panel, a fast sealing speed of 15-40 bags/minute, and is compatible with bags of multiple specifications.

Industrial large-scale model: Priced at $4,000-13,000, it is used in food factories, pharmaceutical companies, etc. It includes a high-precision meter, a high-speed sealing module and a data traceability system, with an output of up to 60-120 bags/minute.

Fully automatic sealing packaging machine purchase suggestions

When purchasing a fully automatic sealing packaging machine, you need to pay attention to parameters such as sealing width, material compatibility, and efficiency:

Sealing width and material compatibility: Make sure the equipment supports the target bag size (such as 400mm width) and material (PE, PP, aluminum foil, etc.).

Production efficiency: Select the sealing speed according to the production capacity requirements, for example, the leisure food production line needs ≥60 packs/minute.

After-sales service: Investigate the supplier's spare parts supply capacity and technical support response speed.

Fully automatic sealing packaging machine manufacturer

Our factory focuses on the research and development and manufacturing of Fully automatic sealing packaging machine, and has accumulated rich industry experience and technical strength. We provide a variety of sealing equipment, such as FS-200, FS-300, FS-500, etc., suitable for different types of material packaging needs. The use of advanced design concepts and high-quality manufacturing processes ensures stable equipment operation, firm sealing, and beautiful packaging. In addition to standardized products, it also supports personalized customization services, and can formulate machine models according to functions, product models, output, etc.

Fully automatic sealing packaging machine application areas

Fully automatic sealing packaging machine is widely used in many industries to ensure that the product maintains integrity during the packaging process and effectively prevents external contamination. In the food field, the equipment can be used to package snacks, condiments, beverages, etc. to ensure the freshness and safety of the products; in the pharmaceutical field, it provides aseptic and highly sealed packaging for pharmaceutical particles, powders or liquids; in the daily chemical industry, such as shampoo, detergent and other product packaging, it can achieve precise quantification and rapid sealing to enhance product competitiveness.