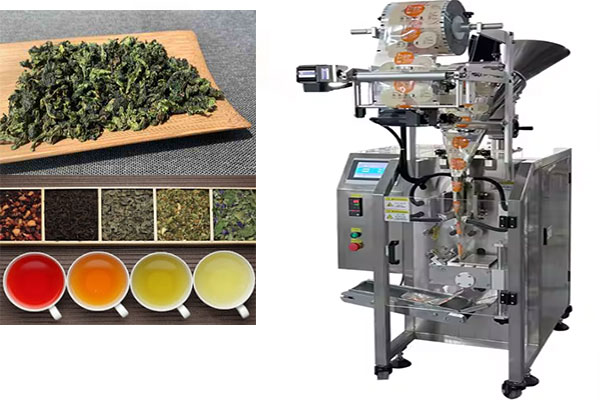

Standard Side-Sealing Packaging Machine

Saturday December-20 2025 18:12:08

The Standard Side-Sealing Packaging Machine is used for side or multi-side heat sealing of flexible packaging materials. The machine controls the sealing temperature, pressure, and duration to ensure a strong and aesthetically pleasing seal. The sealing size is adjustable depending on the machine model, typically ranging from 5-15 mm in width. The sealing speed is 20-80 times per minute, depending on the machine configuration and packaging material. Machines are classified into three types based on the sealing method: vertical three-side sealing, vertical four-side sealing, and horizontal side sealing.

Standard Side-Sealing Packaging Machine Working Principle

Packaging material is fed into the Standard Side-Sealing Packaging Machine. The material passes through a forming device to form a tubular structure. The material is then fed into the tubular material by a metering device. The machine's longitudinal sealing device continuously heat-seals one edge of the material. After sealing, a cutter or slitting mechanism separates the continuous package into individual finished products, completing the packaging process. In horizontal side-sealing packaging machines, the horizontal sealing device cuts and seals the material at a preset length to form individual packaging bags; while vertical machines complete the sealing of three or four sides through continuous motion.

Standard Side-Sealing Packaging Machine Types and Features

Standard side-sealing packaging machines include three common types: vertical three-side sealing, vertical four-side sealing, and horizontal side sealing. Vertical machines are suitable for packaging powders, granules, or liquids in small bags, while horizontal side-sealing machines are suitable for packaging solid or long, rectangular products.

Vertical three-side sealing packaging machines typically seal the left, right, and bottom of the packaging bag. They employ a continuous longitudinal sealing and intermittent transverse sealing structure, with a packaging speed of 30-60 bags per minute. Flexible packaging materials include aluminum foil, composite film, and polyethylene, and are commonly used for packaging granular and powdery products such as snacks and condiments.

Vertical four-side sealing packaging machines seal all four edges. Four-side sealing machines are equipped with a four-sided sealing mechanism and a bag-cutting device. It has a more complex configuration, typically including two film roll systems and a precision alignment device. Packaging speed is 60-100 bags per minute. Suitable for multi-layer composite materials such as aluminum-plastic composite films, providing better moisture protection and freshness preservation. This model is characterized by strong sealing and a smooth appearance.

The horizontal side-sealing packaging machine uses horizontal film feeding and side sealing, completing the packaging of the product in a horizontal position. Packaging speed varies depending on product size, generally between 20-70 pieces per minute. Suitable for thicker packaging materials such as paper-aluminum composites. Suitable for non-flowing materials or single-item products, such as biscuits.

Benefits of the Standard Side-Sealing Packaging Machine

The Standard Side-Sealing Packaging Machine improves packaging efficiency. Automated operation reduces reliance on manual labor in traditional packaging, enabling 24-hour continuous production and reducing labor costs. By controlling temperature, pressure, and speed, the machine avoids common problems in manual operation such as incomplete sealing or deformation, thereby reducing material waste. This type of machine can adapt to the packaging needs of products of different sizes and shapes by changing molds and adjusting parameters. It supports a variety of packaging materials to meet special packaging requirements such as moisture-proof, light-proof, and vacuum sealing.

Standard Side-Sealing Packaging Machine Industry Applications

The Standard Side-Sealing Packaging Machine can package snacks, noodles, candy, frozen foods, tablets, capsules, shampoo bags, wet wipes, cosmetic samples, electronic components, hardware accessories, seeds, dried flowers, and other products.

The Standard Side-Sealing Packaging Machine provides a reliable packaging solution through automated heat-sealing technology. Whether it's a vertical three-side sealing, vertical four-side sealing, or horizontal side-sealing model, it can meet the needs of diverse products and materials. Its sealing control not only ensures product quality and safety but also enhances brand value through standardized production.