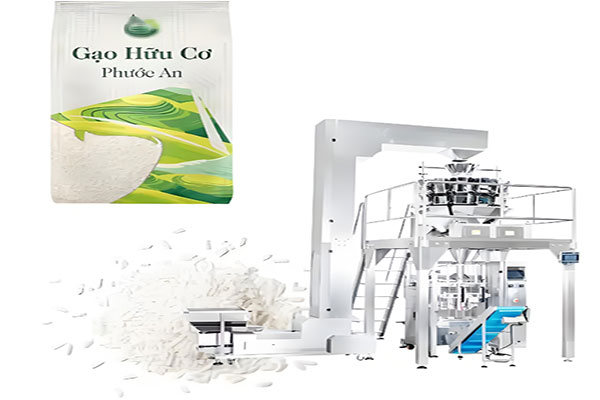

Fully automatic bagging packaging machine

Fully automatic bagging and packaging machines ranges from US$8,000 to US$30,000 , which can meet the needs of enterprises of different sizes. It has gradually become an important equipment for improving efficiency, precision and reducing costs in different industries.

Bagging speed: 10-20 bags/minute

Bag capacity range: 1-50kg

Bag type support: valve bag, open bag

Bagging method: vacuum adsorption clamping

Power supply requirement: 380V three-phase

Air source pressure: 0.6-0.8MPa

Control system: PLC+touch screen

What is Fully automatic bagging packaging machine?

Fully automatic bagging packaging machine has gradually become an important equipment for improving efficiency, precision and reducing costs in different industries. It realizes a continuous and fast packaging process through a series of processes such as automatic conveying, opening bags, and metering, filling and sealing, greatly reducing manual operations. According to different models, the models include the basic FA-BM20, the mid-range FA-BM50 and the high-end FA-BM100. The equipment output range is generally 20 to 100 bags per minute, and the specific speed depends on the material characteristics and machine configuration. The automatic bagging system not only improves the packaging speed, but also ensures the stability of operation and realizes unmanned production. In terms of price, depending on the model and related configuration, the equipment price ranges from USD8000 to USD30000 to meet the needs of enterprises of different sizes.

What are the categories of Fully automatic bagging packaging machine?

Fully automatic bagging packaging machine can be classified according to different application scenarios. First of all, from the packaging method, it can be divided into vertical bagging machine and horizontal bagging machine. Vertical bagging machine is suitable for granular or powdered materials, while horizontal bagging machine is suitable for packaging bulk items such as grain, rice, etc. Secondly, according to production capacity, the machine can be divided into single bag packaging machine and multi-bag parallel packaging machine, the latter is suitable for customers with high requirements for production efficiency. In addition, according to user needs, there are also customized multi-functional equipment, such as high-end models with integrated functions such as automatic metering, weighing, bag sealing, and coding.

Models of fully automatic bagging packaging machine

The models of fully automatic bagging packaging machine are different in terms of output and performance. The specific models are as follows:

The basic FA-BM20 is suitable for small and medium-sized production lines. The packaging speed is about 20 to 40 bags per minute, and the metering range is between 100 grams and 2000 grams. It is mainly suitable for granules and powder materials. The price is about 8000 to 10000 US dollars.

The mid-range model FA-BM50 is equipped with an automatic bagging system, supports multiple bag type switching, and the packaging speed can reach 40 to 70 bags per minute. The metering range is wider, from 100 grams to 5000 grams, suitable for granules, powders and flakes. The price is roughly between 10000 and 20000 US dollars.

The high-end model FA-BM100 has a multifunctional automatic bagging, sealing and coding system, with a packaging speed of 70 to 100 bags per minute, higher metering accuracy, support for complex mixed material packaging, and equipped with intelligent fault detection function, which can adapt to a variety of bag types. The price range is US$20,000 to US$40,000.

What are the core functions of the fully automatic bagging packaging machine?

The core functions of the fully automatic bagging packaging machine include precise metering, automatic bagging, sealing and intelligent control:

Precise metering: The metering system can automatically adjust according to the material characteristics to ensure high accuracy of the packaging weight, and the error is usually controlled within ±0.2%.

Automatic bagging: The bagging module is suitable for a variety of bag types, such as three-side sealed bags, self-supporting bags and back-sealed bags, and automatically completes bag grabbing and bag opening.

Sealing and sealing: The sealing system uses heat sealing, cold sealing or ultrasonic sealing technology to ensure that the packaging is firm and beautiful.

Intelligent control: equipped with a touch screen operation interface to achieve parameter setting, fault diagnosis and production data statistics, improving operation convenience and maintenance efficiency.

Technical specifications of Fully automatic bagging packaging machine

The main technical parameters of Fully automatic bagging packaging machine include packaging speed, metering range, applicable materials, applicable bag width, power specifications, etc.:

Packaging speed: 20-100 bags/minute

Measuring range: 100g to 5000g

Measuring accuracy: ±0.2%~±1.0%

Applicable bag width: 80mm-220mm

Power supply specifications: 220V/380V, power about 2.5kW

Air pressure requirement: 0.6MPa, air volume 0.3m³/min

Machine size: about 1500×800×1700mm

Applicable materials: granules, powders, flakes and small blocks

Control system: PLC+servo drive, touch screen operation

| Equipment Configuration | Parameter Value |

| Packaging speed | 20-100 bags/minute |

| Measuring range | 100g to 5000g |

| Measuring accuracy | ±0.2%~±1.0% |

| Applicable bag width | 80mm-220mm |

| Power supply specifications | 220V/380V, power about 2.5kW |

| Air pressure requirement | 0.6MPa, air volume 0.3m³/min |

| Hopper Capacity | about 1500×800×1700mm |

| Applicable materials | granules, powders, flakes and small blocks |

| Control system | PLC+servo drive, touch screen operation |

Price of Fully automatic bagging packaging machine

The price of Fully automatic bagging packaging machine varies according to function, degree of automation and output. The following is the price range classified by function and output:

Basic type (semi-automatic auxiliary bagging): suitable for simple materials such as powders and granules, with an output of about 300-500 bags/hour and a price range of US$6,000-10,000. Suitable for small and medium-sized factories or start-ups.

Standard type (fully automatic bagging + weighing + sealing): supports a variety of packaging forms (such as stand-up bags, self-supporting bags), with an output of about 600-1,000 bags/hour and a price range of US$10,000-20,000. Widely used in food, feed, chemical and other industries.

High-end type (with automatic bag sorting, coding, and dust removal systems): can achieve unmanned operation, with an output of up to 1,200-1,500 bags/hour and a price range of US$20,000-30,000. Suitable for continuous production needs of large factories.

What are the application cases of the fully automatic bagging packaging machine?

Fully automatic bagging packaging machineIn the food industry, manufacturers use this equipment to package flour, sugar, seasonings, snacks, etc. For example, manufacturers use fully automatic bagging packaging machines to quickly package products such as biscuits and potato chips, reducing the error of manual operation and improving packaging speed and accuracy. In the chemical industry, many companies also choose this type of equipment to package fertilizers, detergents, plastic particles and other raw materials. The equipment can automatically adjust the packaging mode according to different materials to ensure the quality and appearance of the product. In addition, in the daily consumer goods industry, Fully automatic bagging packaging machine can provide companies with fast and hygienic packaging solutions, improve production efficiency, reduce labor costs, and adapt to different market needs.

Purchase suggestions for Fully automatic bagging packaging machine

When purchasing a Fully automatic bagging packaging machine, it is recommended to consider the production capacity requirements, material types, bag type adaptation and budget. First, clarify the daily production target, and reserve 10%-20% of the production capacity margin when selecting the model to cope with production fluctuations. Secondly, according to the material fluidity and packaging requirements, select the appropriate metering method and bagging system. Secondly, confirm whether the types of bags compatible with the equipment can meet the diversified packaging needs in the future. Finally, consider after-sales service and equipment stability, and give priority to manufacturers with good market reputation and technical support. Reasonable configuration and professional customization are the key to ensuring production efficiency and packaging quality.