Fertilizer Granule Packaging Machine

The Fertilizer Granule Packaging Machine has high production capacity, with a production speed of 30-50 bags per minute. It has a flexible packaging range and can meet different needs of 10-50kg per bag. The price is generally around US$3,000-10,000.

Capacity: 30-50 bags/minute

Packaging Range: 10-50 kg/bag

Accuracy: 0.2%

Control System: PLC Touchscreen

Applicable Materials: Granular Fertilizer

What is Fertilizer Granule Packaging Machine?

Fertilizer Granule Packaging Machine is a machine used to automatically meter, fill, and seal fertilizer granules. Its core function is to accurately dispense bulk fertilizer granules (such as nitrogen fertilizer, phosphate fertilizer, potash fertilizer, or compound fertilizer) into bags, bottles, or other containers according to a preset weight or volume, and then seal them. This improves production efficiency, reduces human error, and ensures product standardization. The price of a Fertilizer Granule Packaging Machine generally ranges from US$3,000 to US$10,000, depending on the degree of automation, required production capacity, and equipment type.

Fertilizer Granules are mostly spherical or cylindrical in shape and must maintain a certain hardness. They are prone to moisture absorption and agglomeration, as is the case with urea. Granule uniformity is crucial to packaging efficiency. Some fertilizers, such as ammonium phosphate, are corrosive and pose a threat to metal equipment, so the packaging machine must be made of stainless steel. Furthermore, fertilizers can decompose in high temperatures or humid environments, so the packaging environment must be carefully controlled to ensure their stability.

Fertilizer Granule Packaging Machine Features

The Fertilizer Granule Packaging Machine features automatic weighing, multi-bag adaptability, full process automation, corrosion-resistant stainless steel construction, intelligent PLC control, and dust and environmentally friendly design.

Precise Metering and Filling: Using an electronic scale or screw metering system, the fertilizer granule filling amount is precisely controlled according to the preset weight (e.g., 25kg, 50kg), with an error within ±0.2% to ±0.5%.

Multi-Specification Packaging Switching: Supports quick switching between different packaging specifications (e.g., 5kg small bags to 1-ton large bags) to meet diverse market demands.

Compatible with Multiple Packaging Formats: Compatible with pre-made bags (e.g., PE bags, paper bags) or automatically made bags (e.g., heat-sealed bags, woven bags), adapting to various packaging formats.

Various Sealing Methods: Supports various sealing methods, including heat sealing, seaming, and pneumatic clamping, ensuring a tight seal and preventing fertilizer from moisture and clumping.

Key Component Sealing Design: Key components (e.g., the metering hopper and conveying pipes) feature a sealed design to prevent fertilizer dust leakage and moisture intrusion.

Fertilizer Granule Packaging Machine Parameters

| Model | GFCK-G1 | GFCK-G2 | GFCK-G3 | |

| Applicable scope | Granular materials(e.g.rice,miscellaneous grains,food,pet food) | |||

| Packaging weight | 10-20kg | 25-30kg | 40-50kg | |

| Measuring accuracy | ±50g | |||

| Packaging speed | 10-18 bags/min(slight variation depending on the packaging material, bag size etc.) | |||

| Bag size | Bag width(mm) | 350-450 | 450-550 | 550-650 |

| Bag length(mm) | 630-830 | 800-1000 | 900-1100 | |

| Bag material | Woven bag, Kraft bag, Composite film plastic bag | |||

| Sealing type |

Woven bag: Folding/seaming Kraft bag: Heat sealing/seaming Composite film plastic bag: heat sealing |

|||

What are the types of Fertilizer Granule Packaging Machines?

There are five common types of Fertilizer Granule Packaging Machines: Open-mouth bag packaging machines are low-cost and suitable for large-scale packaging; valve bag packaging machines provide dust-free filling and excellent sealing; small bag packaging machines are fully automatic and produce refined small bags; spiral metering packaging machines prevent material blockage and provide accurate metering; and multi-head packaging machines operate at ultra-high speeds to meet large-scale production needs.

Open-mouth bag packaging machines are suitable for granular or powdered fertilizers such as urea, compound fertilizer, and organic fertilizer. Commonly used bags include woven bags, paper-plastic composite bags, and PE bags, with a typical packaging capacity of 10–50 kg. This machine automatically performs weighing, filling, and sewing via manual bagging. Its adaptability and ease of maintenance make it suitable for packaging a wide variety of fertilizers.

Valve bag packaging machines are primarily used for powdered or fine-granular fertilizers such as ammonium phosphate, potash fertilizer powder, and trace element fertilizers. They use valve bags (paper or woven plastic bags) with a typical packaging capacity of 20–50 kg. These machines automatically fill via a valve port, providing excellent sealing performance, effectively reducing dust, and offering high packaging speeds, making them suitable for dusty production environments.

Another type of fertilizer granule packaging machine is the small bag packaging machine, suitable for packaging high-value-added fertilizers such as water-soluble fertilizers, horticultural fertilizers, and slow-release fertilizers. It uses prefabricated bags or roll-film bags (made of PE or composite film), with a packaging capacity of 0.5–10 kg. It automatically completes bag making, metering, filling, and sealing, resulting in aesthetically pleasing packaging suitable for retail and branded sales.

The spiral metering and packaging machine is suitable for powdered fertilizers with poor flowability, such as organic fertilizer powder and microbial fertilizer. It can be used with open-mouth or pre-made bags, with a packaging capacity ranging from 1–50 kg. This machine utilizes a spiral feed mechanism for precise metering and is well-suited for moisture-absorbing and sticky fertilizers. Its compact design occupies a small footprint.

The multi-head packaging machine is suitable for packaging granular or flake fertilizers with good flowability and low weight, such as micro-granular slow-release fertilizers and controlled-release granules. It typically uses open-mouth or valve bags, with a packaging capacity of 20–50 kg. It utilizes multi-head combined weighing technology for high speed and accuracy, and can quickly switch between different sizes, making it suitable for high-speed and high-precision packaging lines.

How much does a Fertilizer Granule Packaging Machine cost?

The Fertilizer Granule Packaging Machine can be used in conjunction with equipment such as bucket elevators, screw conveyors, and conveyor belts. Prices typically range from US$35,000 to US$10,000. Basic semi-automatic models, priced between $3,500 and $6,000, are suitable for small to medium-sized factories with production capacities of 500-1,000 bags/hour and require manual assistance. Fully automatic standard models, priced between $6,000 and $9,000, include automatic weighing and bag sewing functions and have production capacities of 1,500-3,000 bags/hour, making them suitable for medium-sized factories. High-end intelligent models, priced over $10,000, are equipped with PLC control and brand-name motors, with production capacities exceeding 4,000 bags/hour and are suitable for large production lines.

What are the uses of Fertilizer Granule Packaging Machines?

The Fertilizer Granule Packaging Machine has a wide range of applications. In fertilizer production plants, it enables large-scale fertilizer packaging, improving packaging efficiency and ensuring accurate metering. Agricultural supply distribution centers leverage its rapid packaging capabilities to meet sales demands for various sizes, ranging from 5kg to 50kg. Agricultural cooperatives use it for small-batch customized packaging, effectively reducing labor costs. In organic and biofertilizer production, it can provide moisture-proof and sealed packaging for granular organic and microbial fertilizers. Furthermore, the chemical industry often uses it to package granular chemical raw materials, such as salts and feed additives.

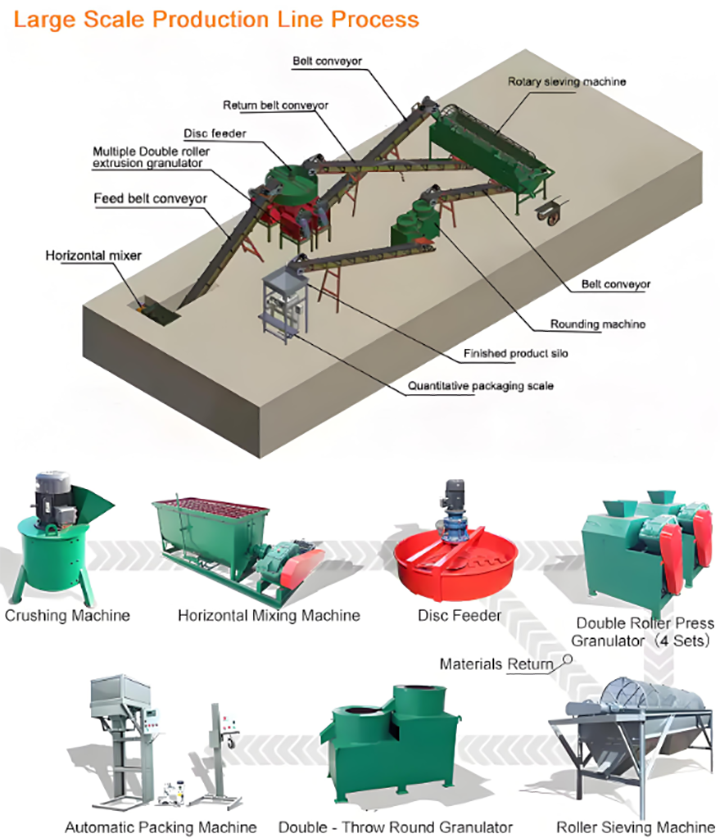

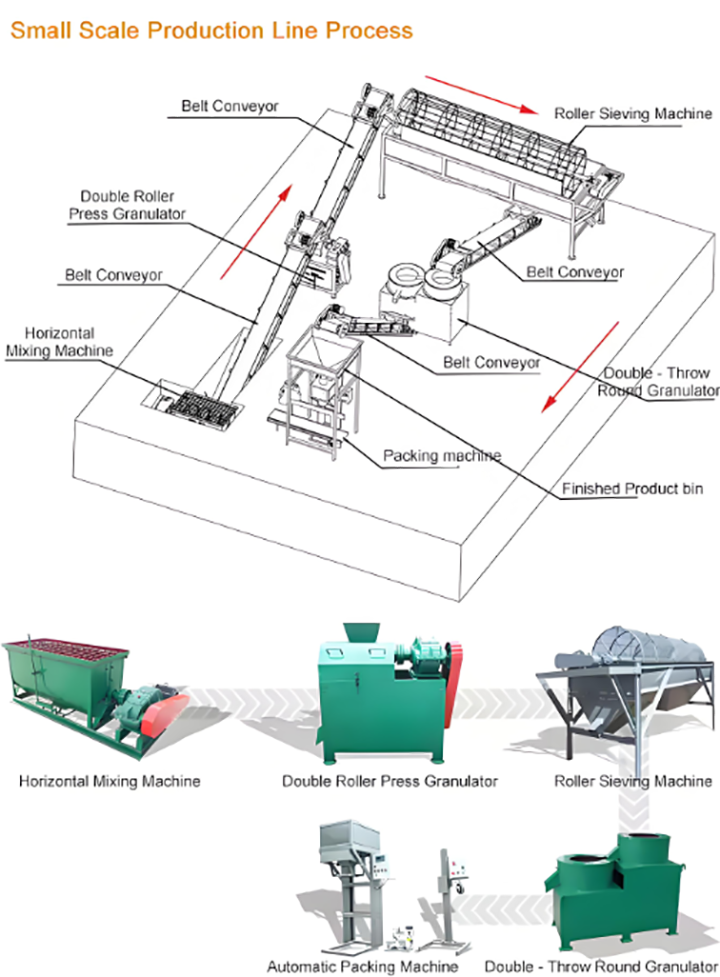

Fertilizer Granule Packaging Machine Production Line

Fertilizer Granule Packaging Machine Supplier

As a manufacturer of Fertilizer Granule Packaging Machines, our factory has many years of industry experience and accumulated technical expertise. Our fertilizer granule packaging machines utilize advanced automated control systems to ensure a precise and efficient packaging process. The modular design allows for quick adaptation to different fertilizer granule sizes and packaging requirements, significantly reducing customer costs. Its compact structure and easy operation make it suitable for a variety of granular fertilizer packaging needs. Our factory can customize equipment according to customers' different production requirements and adjust equipment functions according to specific requirements. We also support trial runs with materials.