Combined Weighing And Packaging Machine With Vacuum Feeder

Combined Weighing And Packaging Machine With Vacuum Feeder common models include CWVP-100, CWVP-200 and CWVP-300, with a corresponding output of about 800 to 3000 bags/hour, suitable for production lines of different sizes. The overall price range is about US$18,000 to US$50,000.

Weighing range: 10g - 3000g

Packaging speed: up to 70 bags/minute

Suction method: vacuum automatic feeding

What is Combined Weighing And Packaging Machine With Vacuum Feeder?

Combined Weighing And Packaging Machine With Vacuum Feeder is a device that integrates high-precision weighing, stable conveying and automatic packaging. The vacuum suction system is used to achieve dust-free and high-speed conveying of powder or granular materials, ensuring accurate weighing and consistent packaging, significantly improving packaging efficiency and daily output. Common models include CWVP-100, CWVP-200 and CWVP-300, with a corresponding output of about 800 to 3000 bags/hour, suitable for production lines of different sizes. The equipment has a compact structure, easy operation, a high level of automation, and supports customization. The overall price range is about US$18,000 to US$50,000, which is cost-effective and suitable for customers pursuing high production capacity and stability.

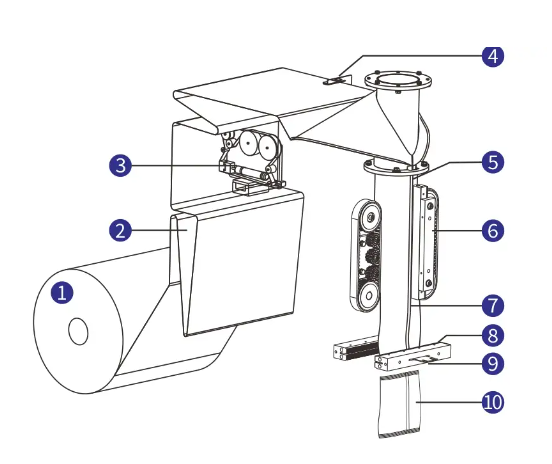

Process flow chart of Combined Weighing And Packaging Machine With Vacuum Feeder

Combined Weighing And Packaging Machine With Vacuum Feeder is composed of film, guide tensioning, coding position, color code tracking, forming, longitudinal sealing, filling, transverse sealing, cutting and other structures.

Film: As a packaging material, it is used to wrap products to protect, isolate and display products.

Guide Tensioning: Ensure that the film maintains appropriate tension during transportation to prevent the film from deviating and wrinkling, and ensure the smooth progress of subsequent packaging processes.

Coding Position: Coding the film at this position, and information such as production date, batch number, shelf life, etc. can be printed to facilitate product traceability and management.

Color Code Tracking: By detecting the color code on the film, the packaging position is accurately controlled to ensure the accuracy and consistency of the packaging, so that the pattern and size of each package meet the requirements.

Forming: Process the flat film into a shape suitable for the packaged product, such as a bag, to prepare for the subsequent filling of the product.

Vertical Seal: Seal the longitudinal edges of the formed film to form the side seal of the packaging bag to prevent product leakage.

Filling: Accurately fill the product to be packaged into the formed and vertically sealed packaging bag by vacuum suction and other methods.

Horizontal Seal: Seal the packaging bag containing the product horizontally to complete the sealing of the packaging bag and ensure the product is sealed and preserved.

Cut: Cut the packaging bag that has completed horizontal sealing from the continuous film to form an independent packaging product.

Finished Product Output: The cut finished packaging product is transported to the designated location for subsequent sorting, packing and other operations.

What are the advantages of Combined Weighing And Packaging Machine With Vacuum Feeder?

Combined Weighing And Packaging Machine With Vacuum Feeder integrates weighing, feeding and packaging, which is accurate and fast, saving manpower and space. The following are common advantages:

Automation integration, double efficiency: weighing, feeding and packaging are integrated, saving labor, improving the overall production rhythm, and suitable for large-scale continuous operations.

Accurate weighing, lower loss: equipped with high-precision multi-head scale, automatic adjustment of feeding amount, small weighing error, effective control of material usage, and reduced loss.

Compact structure, saving space: The overall layout of the equipment is scientific, with a small footprint, suitable for various types of plant space, and convenient for on-site management and operation and maintenance.

What are the technical parameters of Combined Weighing And Packaging Machine With Vacuum Feeder?

The common technical parameters of Combined Weighing And Packaging Machine With Vacuum Feeder are mainly CWVP series, covering a variety of specifications, wide weighing range, fast speed, compact structure, and suitable for a variety of bag types and application scenarios.

| Parameter Name | CWVP-100 | CWVP-200 | CWVP-300 |

| Weighing Range | 10-1000 grams | 50-2000 grams | 100-3000 grams |

| Packaging Speed | 20-40 packs/minute | 30-50 packs/minute | 40-70 packs/minute |

| Vacuum Suction Power | 0.75 kW | 1.1 kW | 1.5 kW |

| Packaging Bag Size | Width 50-150mm, Length 70-300mm | Width 80-200mm, Length 100-350mm | Width 100-250mm, Length 150-400mm |

| Equipment Size (L×W×H) | 1200×800×1800mm | 1500×900×2000mm | 1800×1000×2200mm |

| Power Supply Requirements | 220V/50Hz | 220V/50Hz | 220V/50Hz |

| Equipment Weight | 350kg | 450kg | 600kg |

| Control System | PLC + Touch Screen | PLC + Touch Screen | PLC + Touch Screen |

Application of Combined Weighing And Packaging Machine With Vacuum Feeder

Combined Weighing And Packaging Machine With Vacuum Feeder is suitable for a variety of powdery and granular materials with good fluidity, such as milk powder, starch, seasoning, feed additives, chemical powder, etc. The vacuum conveying system is used to realize dust-free automatic feeding, and with the high-precision weighing module, the error can be controlled within ±0.2%.

Combined Weighing And Packaging Machine With Vacuum Feeder has strong compatibility in packaging bag types. It can handle a variety of pre-made bags such as self-supporting bags, four-side sealed bags, aluminum foil composite bags, etc. The bag size range is usually between 100g-25kg. The equipment integrates bag making-filling-sealing functions, which is particularly suitable for materials that are easy to absorb moisture, and prolongs the shelf life through vacuum or nitrogen filling processes. The whole machine is made of 304 stainless steel, which meets the GMP standards of the food and pharmaceutical industries, significantly improves packaging efficiency and reduces labor costs.

What are the cases of Combined Weighing And Packaging Machine With Vacuum Feeder?

Combined Weighing And Packaging Machine With Vacuum Feeder solves dust pollution through vacuum feeding, and achieves high accuracy of ±0.1% combined with the weighing system. It is widely used in industries that require closed conveying, significantly improving the level of automation and product consistency.

Food industry: used for automatic weighing, vacuum conveying and packaging of powdered materials such as milk powder and coffee powder to ensure accuracy and hygiene.

Chemical industry: Processing of granular or powdered chemical raw materials (such as additives), vacuum feeding to avoid dust, and integrated weighing and packaging to improve efficiency.

Pharmaceutical production: High-precision metering and aseptic delivery of drug powder or granules, in compliance with GMP standards.

Agricultural feed: Vacuum suction, dynamic weighing and quantitative packaging of premixes or vitamin powders to reduce waste.

Price information of Combined Weighing And Packaging Machine With Vacuum Feeder

The price of Combined Weighing And Packaging Machine With Vacuum Feeder varies according to the model and configuration. The following are the common prices of each model.

CWVP-100 is a basic model suitable for daily production use of small and medium-sized enterprises, with a daily output of about 800-1600 bags and a price generally between US$18,000 and US$25,000. It is suitable for light and medium load materials such as granules and powders, supports the adjustment of standard packaging bag width and length, and is simple to operate and easy to maintain.

CWVP-200 is a mid-level model with a daily output of 1500-2500 bags, suitable for enterprises with medium to high production capacity, and a price range of US$28,000 to US$35,000. The machine is equipped with an enhanced weighing system and a high-power vacuum feeder, which is more adaptable and more stable.

CWVP-300 is a high-end model for enterprises with high production demand, with a daily output of 2500-4000 bags, suitable for continuous large-scale operations, and a price range of US$38,000 to US$50,000. It supports mixed feeding of multiple materials, intelligent weighing feedback and automatic fault diagnosis system, making it an ideal choice for large-scale production lines.

How to choose a suitable Combined Weighing And Packaging Machine With Vacuum Feeder manufacturer?

When choosing a manufacturer of Combined Weighing And Packaging Machine With Vacuum Feeder, you should focus on its production experience, technical capabilities, customization level and after-sales service. High-quality manufacturers should have a complete R&D system, strict quality control and stable delivery capabilities. Our factory is experienced in manufacturing this equipment. Common models of Combined Weighing And Packaging Machine With Vacuum Feeder produced by our factory include DH-CWVP-100, DH-CWVP-200 and DH-CWVP-300. Taking DH-CWVP-200 as an example, the weighing range is 50g-2000g, the packaging speed can reach 30-50 bags/minute, and the vacuum feeding power is 1.1kW, which is suitable for a variety of materials such as granules and powders. The equipment is equipped with a PLC intelligent control system, which supports packaging requirements of bag width 80-200mm and bag length 100-350mm. The overall design is compact and the operation is stable to meet different production needs.