Candy Granule Packaging Machine

Candy Granule Packaging Machine packaging speed generally ranging from 30 to 120 bags per minute, with some high-speed models reaching 200 bags per minute. As for price, with standard models ranging from $5,000 to $9,000.

Packaging Speed: 30–200 bags/minute

Weighing Accuracy: ±0.2–1.0g

Packaging Range: 5–1000g

Applicable Film Materials: OPP/Laminated Film/Aluminum Foil/Paper Film

Power Supply: 220V/50Hz

What is Candy Granule Packaging Machine?

Candy Granule Packaging Machine is suitable for packaging a variety of candy granules, including cubes, spheres, and long strips. Candy can vary in properties, from hard and unbreakable to crisp and brittle, and from sticky to sticky. The adjustable packaging mechanism effectively prevents breakage and sticking.

The Candy Granule Packaging Machine supports a variety of packaging materials, including OPP film, laminated film, aluminum foil, and paper film, meeting the freshness, moisture-proofing, and aesthetic requirements of different products. Packaging formats are also flexible, with common options including back-seal bags, three-side seal bags, four-side seal bags, stick bags, pillow bags, as well as small and large bags, catering to both retail and wholesale needs. In terms of packaging speed, the efficiency of the machine can be selected based on production capacity requirements, generally ranging from 30 to 120 bags per minute, with some high-speed models reaching 200 bags per minute. As for price, the market range for candy granule packaging machines varies greatly, with standard models ranging from $5,000 to $9,000, while high-speed, intelligent models may cost between $10,000 and $20,000.

Candy Granule Packaging Machine Bag Type

Advantages of Candy Granule Packaging Machines

The advantages of candy granule packaging machines lie primarily in their intelligent and user-friendly control systems. Most machines feature a touchscreen interface and a PLC control system, enabling multi-language switching, visual parameter adjustment, and production data logging, allowing operators to quickly learn and reduce training costs. Furthermore, the intelligent control system automatically detects bag length and adjusts sealing temperature and speed during the packaging process, avoiding waste caused by manual errors. Furthermore, some high-end machines are equipped with remote monitoring modules, allowing production managers to view equipment status in real time via the internet, facilitating production management and maintenance.

Candy Granule Packaging Machine Specifications

| Model | LD-420 | LD-520 | LD-720 | LD-900 | LD-1050 | LD-1200 |

| Film Thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm | 100-600mm | 100-800mm | 100-1000mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm | 260-430mm | 290-505mm | 290-580mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | 400mm | 400mm | 400mm |

| Pakaging Rate | 5-60 bags/min | 5-60 bags/min | 5-55 bags/min | 5-20 bags/min | 5-20 bags/min | 5-20 bags/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.720mm | Max.900mm | Max.900mm | Max.1200mm |

| Measurement Range | 150-1500ml | 5-2000ml | 4000ml | 1-25L | 1-25L | 1.5L-45L |

What types of candy granule packaging machines are available?

Currently, candy granule packaging machines on the market mainly include measuring cup packaging machines, multi-head weigher high-speed packaging machines, and fully automatic intelligent packaging machines.

Measuring cup candy granule packaging machines: With a relatively simple structure and a price range of US$5,000-9,000, they are suitable for small and medium-sized businesses or customers with low packaging precision requirements. They are suitable for packaging candies with uniform specifications and small weight variations, such as hard candies, mints, and small lollipop granules, meeting basic measuring and packaging needs.

Multi-head weigher high-speed candy granule packaging machines: With a wide range of applications, fast speed, and high accuracy, they are generally priced between US$9,000 and US$13,000 and are the mainstream choice for candy companies. This machine is suitable for packaging irregularly shaped candies with large weight variations or relatively fragile candies, such as bonbons, chocolate chips, jelly granules, and gummy candies. It ensures high production speed while improving measuring accuracy and preventing breakage.

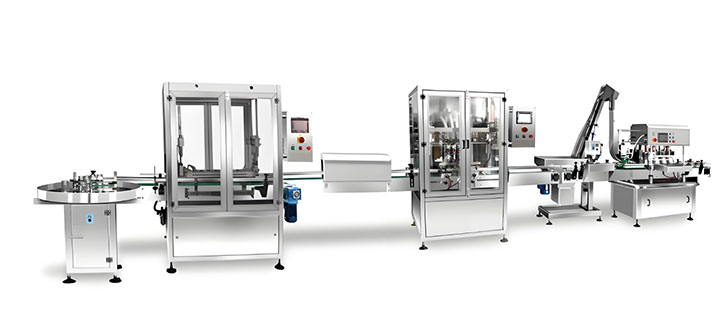

The fully automatic intelligent Candy Granule Packaging Machine: This machine features high integration and seamless integration with conveyor lines, metal detectors, and cartoning systems. It boasts a high degree of automation and is priced between $14,000 and $20,000. This equipment is suitable for high-end branded candies and mixed-assortment products, such as gift boxes, mixed-flavor gummy candies, and chocolate gift packs. It meets the demands of large-scale, intelligent production while ensuring aesthetically pleasing and uniform packaging.

Customized packaging lines: These are tailored to the customer's product characteristics and production volume requirements and may include modules such as automatic material handling, nitrogen filling, and moisture-proofing. The total investment can exceed $20,000. This machine is particularly suitable for candies with extremely high quality requirements or special characteristics, such as fragile wafers, sticky gummy candies, moisture-resistant chocolates, or high-end handmade candies. Customized solutions ensure packaging quality and product preservation.

Candy Granule Packaging Machine Features

The Candy Granule Packaging Machine's functional design balances precision and efficiency. For weighing granular candies, multi-head weighers offer high precision and speed, making them suitable for large-scale production. Measuring cup weighers are more economical and suitable for customers with lower precision requirements. A high degree of automation is a key indicator of equipment advancement. These weighing machines typically include automatic loading, weighing, sealing, and date printing, significantly reducing manual intervention and improving production efficiency. Regarding operational stability, high-quality equipment ensures continuous and smooth operation over extended periods, minimizing problems such as bag jams, leaking seals, and weak heat seals. Furthermore, as food processing equipment, easy cleanability is essential. Contact parts of candy granule packaging machines are primarily constructed of 304 or 316 stainless steel, meeting food safety standards while facilitating daily cleaning and maintenance to prevent secondary contamination.

Candy Granule Packaging Machine Suppliers

When selecting a candy granule packaging machine, the supplier's strength and service capabilities are crucial considerations. Our factory has a successful market track record, a comprehensive R&D team, and advanced production equipment, enabling us to provide both standardized and customized solutions tailored to our customers' diverse needs. Designed with precision and stability in mind, the equipment is constructed from 304/316 stainless steel, meeting food safety standards. It also features easy operation, low maintenance, and high efficiency. The company also provides operator training and rapid after-sales response, ensuring customers can quickly and stably begin production.

Candy Granule Packaging Machine Application