Bag-feeding powder packaging machine

Bag-feeding powder packaging machines typically cost between $5,000 and $30,000 USD. They can package everything from small packages of a few dozen grams to large packages of several kilograms. They support common standard capacities such as 1 kg, 2 kg, and 5 kg, and custom sizes are also accepted. Packaging Speed: 40-60 bags/minute Measuring Method: Servo screw/combination weigher Bag Size: 50-180mm x 40-130mm (customizable) Applicable Materials: Powders such as milk powder and condiments Power Supply: 220/380V 1.5-2.2kW

What is bag-feeding powder packaging machine?

Bag-feeding powder packaging machine often use screw metering, which reduces spillage of materials such as flour, coffee powder, milk powder, and laundry detergent. The metering error is typically controlled within ±1%.

Parts of the bag-feeding powder packaging machine that come into contact with the material are typically made of 304 or 316 stainless steel, making them durable and corrosion-resistant. The packaging speed typically ranges from 15 to 80 bags per minute. It supports three-side seal bags, four-side seal bags, stand-up pouches, and flat bags, meeting the packaging needs of various powder products.

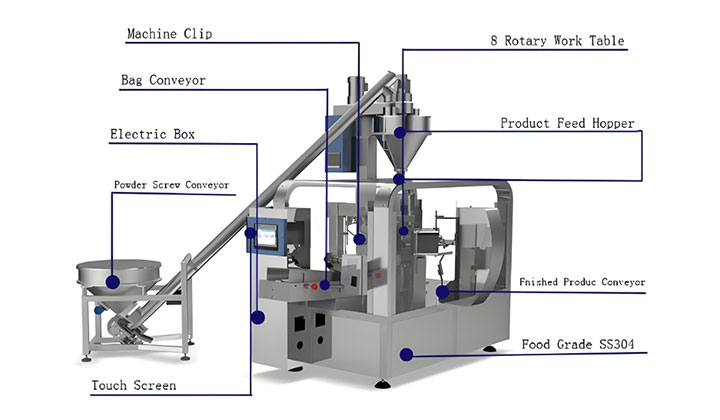

What are the structural components of a bag-feeding powder packaging machine?

The bag-feeding powder packaging machine primarily consists of the following components: an automatic bag loading device, a bag storage system, a bag opening mechanism, a metering and filling system, an exhaust system, a heat sealing mechanism, a transmission system, and a control system.

The operating principle is as follows: The control system issues a command, and the transmission system transports empty bags to the workstation. Subsequently, the automatic bag loading device retrieves a bag from the bag storage, and the bag opening mechanism precisely opens the bag using a suction cup. The metering and filling system immediately pours a precisely measured amount of powder into the bag, while the exhaust system removes air from the bag to prevent splashing. After filling, the bag is transported to the heat sealing mechanism for heat sealing. Finally, the finished bag is delivered by the transmission system.

What are the advantages of a bag-feeding powder packaging machine?

Bag-feeding powder packaging machines offer significant advantages: significantly improved production efficiency, with automated operation speeds reaching 5-10 times that of manual operation. High metering accuracy reduces material waste and lowers costs. The enclosed design offers easy cleaning and superior hygiene, meeting food and pharmaceutical requirements. High flexibility allows adaptation to various bag types and materials by changing molds and adjusting parameters. Reliable operation, equipped with an advanced control system and fault alarms, ensures stable production. Integrated inkjet traceability supports batch numbers and dates, meeting quality management requirements.

Bag-feeding powder packaging machine parameters

| VFFS -320 | VFFS-420 | VFFS-520 | VFFS-720 | |

|---|---|---|---|---|

| Packing Speed | 5-70bags/min | 5-60bags/min | 5-50bags/min | 5-40bags/min |

| Bag Length | 50-200mm | 80-300mm | 100-400mm | 100-450mm |

| Bag Width | 50-150mm | 50-200mm | 100-250mm | 100-350mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | Max.320mm |

| Filling Range | 50-800ml | 150-1200ml | 200-2000ml | 250-4000ml |

| Film Width | Max. 320mm | Max. 420mm | Max. 520mm | Max. 720mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Air Consumption | 0.3m3/min 0.65MPa | 0.3m3/min 0.65MPa | 0.4m3/min 0.65MPa | 0.4m3/min 0.65MPa |

| Voltage | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz |

| Power | 2.0kw | 2.2kw | 4kw | 4.5kw |

| Machine Dimensions | 117*82*129cm | 132*95*136cm | 149*108*149cm | 172*126*182cm |

| Machine Weight | 350kg | 550kg | 750kg | 850kg |

What types of bag-feeding powder packaging machines are there?

Bag-feeding powder packaging machines primarily include vertical, spiral vertical, multi-lane, and large bag models. These machines differ in their structure, metering method, station, and capacity, meeting diverse packaging needs for small bags at high speed and high precision, medium-volume packaging, and large bags with heavy loads.

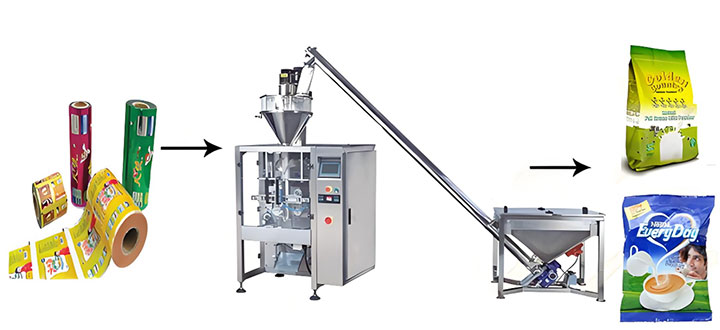

Vertical Bag-feeding powder packaging machine: Using roll film for on-site bag making, the machines integrate bag making, metering, filling, and sealing. The compact design and minimal footprint make changing materials and sizes quick and easy.

This equipment is suitable for a variety of bag types, including three-side seal bags, back-seal bags, and gusseted stand-up pouches. Its packaging speed is typically medium-to-low, approximately 20-50 bags/minute, and it is suitable for small-volume packaging, typically ranging from 1g to 1000g.

Vertical bag-feeding powder packaging machine with Screw: Based on a vertical machine, it utilizes a screw-type metering mechanism, making it the preferred metering method for powder packaging. It offers extremely high metering accuracy, can effectively handle powders with varying flow properties, and is dust-resistant.

This equipment is suitable for a variety of bag types, including three-side seal bags, back-seal bags, and stand-up pouches. Its packaging speed varies significantly depending on material properties and precision requirements, typically ranging from 15-45 bags/minute. It is suitable for small to medium-volume packaging, with typical packaging capacities ranging from 5g to 5000g.

Multi-lane bag-feeding powder packaging machine: This machine consists of multiple vertical machines (typically 2-14 lanes) connected in parallel, operating synchronously. This is equivalent to running multiple production lines in parallel, offering extremely high production efficiency and is ideal for large-volume production.

This machine is designed for small-sized three-side-seal and back-seal bags. It boasts extremely high packaging speeds, reaching hundreds of bags per minute. It's ideal for small-volume packaging, typically ranging from 1g to 100g. Typical applications include stick packs of seasonings, ground coffee, and other products.

Large Bag Bag-feeding powder packaging machine: Designed for large, heavy-duty packaging. Featuring a robust structure, it typically features a high-capacity screw or gravity-feeding system and a high degree of automation, often integrating automatic bag loading and robotic palletizing.

This machine is used for pre-formed large, open-top bags, such as valve bags, PE bags, and woven bags. While packaging speeds are slower, it prioritizes precision and stability, typically running 2-10 bags per minute. It's suitable for large-volume packaging applications, ranging from 5kg to 50kg or even higher.

Bag-feeding Powder Packaging Machine Price

Semi-automatic bag-feeding powder packaging machines offer basic functionality, primarily performing basic operations such as metering, filling, and bag sealing. They are relatively affordable, typically ranging from $3,000 to $10,000, making them suitable for small-scale production or startups with limited budgets. Fully automatic bag-feeding powder packaging machines are the most common type. They offer comprehensive functionality, automating the entire bag-making, metering, filling, sealing, coding, and counting processes. Optional features include nitrogen filling for freshness preservation, weight rejection, and material level detection. Prices range from approximately $10,000 to $20,000, increasing depending on the number of filling heads, accuracy, and optional features. Fully automatic rotary bag-feeding powder packaging machines, suitable for ultra-large-scale production, integrate the highest levels of automation and intelligence. They feature dozens of workstations and incorporate advanced features such as high-precision weighing, visual inspection, and robotic palletizing to maximize production capacity. Consequently, they command the highest prices, typically starting at over $20,000.

What are the features of bag-feeding powder packaging machines?

The bag-feeding powder packaging machine can automatically grasp and precisely open pre-made bags made of various materials and specifications, such as composite film and aluminum foil bags, without manual intervention. Using a screw or weighing system, it precisely controls the filling volume of materials such as flour, milk powder, and seasoning powder, ensuring consistent weight per bag and minimizing waste. After filling, the bag is automatically heat-sealed (some models support vacuum sealing), and trimming and embossing are also available as needed to prevent moisture and leakage. The finished packages are automatically transported to the next stage. High-end models also feature integrated weight detection and leak detection to automatically reject defective products. The machine supports a variety of powder materials, such as those that are prone to moisture absorption and dust generation. Parameters such as fill volume and sealing temperature can be quickly adjusted via the touchscreen, making it suitable for small-batch, multi-product production.

What powder materials are suitable for the bag-feeding powder packaging machine?

Bag-feeding powder packaging machine is used for powder materials in many industries such as milk powder, protein powder, seasoning, flour, powdered sugar, dye, coating, plastic powder, detergent, pharmaceutical powder, traditional Chinese medicine powder, health care products, fertilizer, seed treatment agent and metal powder.