Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine can adapt to a variety of bag types and food types. The packaging speed of this machine is usually 20-50 bags/minute, suitable for prefabricated self-supporting bags, three-side sealed bags, four-side sealed bags, zipper bags and other packaging forms. Depending on the configuration, the price range is between US$8,000-30,000. Capacity: 1200-1500 bags/hour Power supply: 380V/50Hz Power: 5.5kW Machine weight: about 800kg Applicable products: pre-prepared dishes, frozen foods, etc. Control method: PLC touch screen Air source requirements: 0.6-0.8MPa Cooling method: water cooling/air cooling optional Dimensions: 1500×1200×1800mm

What is Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine?

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine works with the pre-made bag feeding system through a rotary vacuum chamber to achieve a fully automated process of bag taking, bag opening, filling, vacuuming, and sealing. The equipment is suitable for vacuum packaging of various frozen products such as dumplings, glutinous rice balls, vegetables, meat, seafood, etc. Its main features include high degree of automation, fast packaging speed, high vacuum degree, excellent sealing performance, and can adapt to a variety of bag types and food types. The packaging speed of this machine is usually 20-50 bags/minute, suitable for prefabricated self-supporting bags, three-side sealed bags, four-side sealed bags, zipper bags and other packaging forms. Depending on the configuration, the price range is between US$8,000-30,000, suitable for small, medium and large food processing companies.

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine Working Steps

The workflow of Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine mainly includes the following steps: the robot arm accurately grabs the pre-made bag at the bag picking station, transports it to the bag opening station, opens the bag opening by vacuum adsorption and photoelectrically detects abnormalities; the filling station uses a servo motor to drive the screw metering, which is suitable for materials such as particles and powders; then enters the double vacuum chamber to seal, ensuring low-temperature sealing strength; finally, it is quickly cooled by the water cooling system, and the finished product is automatically stacked and output by the conveyor belt.

What are the characteristics of Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine?

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine adopts rotary intermittent filling and continuous vacuum design. It is equipped with a stainless steel vacuum chamber and a transparent observation window to facilitate real-time monitoring of the vacuum status. Its core functions include automatic bag taking, bag opening, metering filling, vacuum pumping and heat sealing, and it is suitable for various pre-made bag types such as side-sealed bags, self-supporting bags, zipper bags, etc. It supports precise filling of various materials (such as solids, particles, sauces, etc.) and has efficient vacuum pumping function to ensure packaging quality and preservation effect. The equipment integrates a PLC intelligent control system, which can accurately adjust the vacuum degree, sealing temperature and packaging speed. The equipment is equipped with no bag no filling, abnormal air pressure alarm and fault code display functions to ensure the stability and hygiene of the frozen food packaging process.

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine Technical Parameters

|

Model

|

LG1-430A

|

|

Bag Material

|

Multilayer Composite Premade Bag (e.g.: PET/PE)

|

|

Bag Type

|

3 Side Seal Bag, Stand-up Bag

|

|

Upgradable Bag Type

|

Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device)

|

|

Size Range

|

80mm≤W≤300mm 100mm≤L≤430mm

|

|

Speed

|

0~15bags/min

|

|

Sealing Type

|

Straight grain, pitch is 1mm (Optional reticulate)

|

|

Sealing Width

|

10mm (5--20mm can be customized)

|

|

Voltage

|

220V, Single-phase, 50/60HZ, 1.2KW

|

|

Air Pressure

|

0.65Mpa

|

|

Air Consumption

|

0.3m³/min (Standard machine, no additional function)

|

|

Body Dimension

|

1770*600*1360mm

|

|

Packing Dimension

|

1860*710*1650mm (Export non-fumigation wooden case)

|

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine Machine Type

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine is a core equipment for food processing, suitable for automatic vacuum packaging of various frozen foods. It is divided into vacuum rotation, nitrogen filling preservation, multi-station rotation, high temperature sterilization, liquid special and other models. Each model is suitable for different products, output and characteristics.

Vacuum Rotary Packaging Machine

Applicable products: solid frozen foods packaged in self-supporting bags and zipper bags (such as dumplings, wontons, meatballs, etc.).

Output: The single-station model has a production capacity of about 800~1,200 bags/hour, and the double-station model can reach 1,500~2,500 bags/hour.

Price range: $10,000 - $25,000.

Features: Continuous rotary operation, high stability, suitable for small and medium-sized food processing companies.

Nitrogen-filled fresh-keeping vacuum packaging machine

Applicable products: high-end frozen foods (such as seafood, pre-prepared dishes, prepared meat products, etc.) that need to extend the shelf life.

Production: Single machine capacity 1,000~1,800 packs/hour, high-speed models can reach 2,500 packs/hour.

Price range: $15,000 - $30,000.

Features: Nitrogen is filled after vacuuming to inhibit oxidation and extend the shelf life by 30%~50%.

Multi-station rotary packaging machine (fully automatic)

Applicable products: frozen foods produced in large quantities, such as quick-frozen dumplings, buns, hot pot ingredients, etc.

Production: 6-8 station design, production capacity can reach 3,000-6,000 packs/hour, and some high-end models exceed 8,000 packs/hour.

Price range: $30,000 - $40,000.

Features: Fully automatic bagging, bag opening, filling, vacuuming, and sealing are integrated, suitable for large food factories.

High-temperature sterilization vacuum packaging machine

Applicable products: Frozen foods that require high-temperature sterilization (such as ready-to-eat meat, marinated products, etc.).

Output: 1,200-2,000 packs/hour for a single machine, and up to 3,000 packs/hour for customized models.

Price range: $2,000 - $40,000.

Features: High-temperature resistant conveyor belt + double seal, support 121℃ high-temperature sterilization, and extend shelf life.

Liquid frozen food packaging machine

Applicable products: soups, sauces, liquid condiments, etc.

Output: Anti-drip filling, production capacity 800-1,500 packs/hour, high-precision models up to 2,000 packs/hour

Price range: $10,000 - $30,000.

Features: Inclined vacuum chamber design to avoid liquid splashing and ensure tight sealing.

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine Applicable Bag Type

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine is designed for pre-made bags and is suitable for a variety of bag types to achieve vacuum packaging of frozen food. In terms of bag compatibility, it is compatible with three-side sealed prefabricated bags, standard three-dimensional bags or flat bags, with strong sealing, suitable for granular and block frozen foods such as seafood and meat; back-sealed bags, single-sided printed upright bags, are convenient for product display and are often used for quick-frozen pastries and pre-prepared dishes; self-supporting bags, prefabricated bags with bottom support, are suitable for liquid frozen foods such as sauces and soups, and can be placed upright to save space; the material is suitable for composite films (such as PET/PE, NY/PE) and other low-temperature resistant and puncture-resistant materials to ensure that they will not crack in a frozen environment; the size range usually supports bag widths of 100-300mm and bag lengths of 150-450mm, and can be customized to adapt to larger or special-shaped bags; in addition, it also has a special design, the vacuum system optimization can avoid frost in the bag, and the rotary station can accurately align the prefabricated bag opening to improve the sealing efficiency.

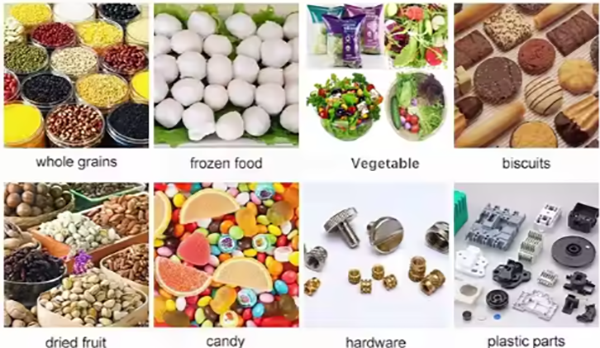

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine Application Field

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine is used in various frozen food companies, including:

Frozen meat: such as beef, chicken, seafood, etc., through vacuum sealing to effectively prevent frostbite and oxidation, extend the shelf life, and keep the meat fresh and tender.

Quick-frozen vegetables: such as peas, corn, mixed vegetables, etc., isolate oxygen, lock nutrients and moisture, avoid ice crystal formation, and ensure taste and quality.

Prepared food: dumplings, buns, pizza, etc., leak-proof and moisture-proof packaging, convenient for long-term storage and transportation, and maintain the original flavor of the food.

Ready-to-eat food: frozen rice, noodles, etc., provide high barrier packaging to prevent odor and deterioration, and facilitate consumers to heat and eat directly.

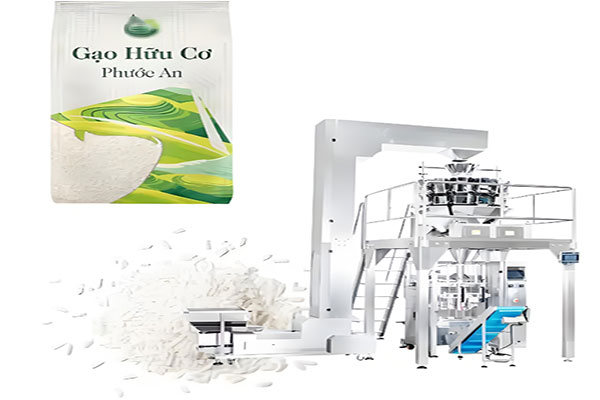

Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine Solution

For frozen food processing plants, the Automatic Rotary Pre-made Pouch Frozen Food Vacuum Packing Machine can provide personalized configurations based on the customer's specific product characteristics, production capacity requirements, bag design, etc., such as modular options such as multi-head combination scales, liquid filling devices, vacuum system customization, and automatic labeling and coding systems. By seamlessly connecting with the conveying system, cold chain system, and terminal packaging equipment, a complete frozen food intelligent packaging production line is built, thereby effectively improving the overall factory automation level and market competitiveness.