Automatic Liquid Sachet Packing Machine

Automatic Liquid Sachet Packing Machine can pack a variety of bag styles, three-side sealed liquid bags, back-sealed bags , special-shaped bags , continuous bag type bags , etc.the packaging speed is generally 30-100 bags/minute, and the metering accuracy error is controlled between ±0.2%-3%. The price is usually between US$650-8000. Speed: 30-100 bags/minute Capacity: 5-30ml liquid/sauce Film width: 100-300mm Bag size: 50-150mm long, 30-100mm wide Power supply: 220V/380V, 1.5kW Air source: 0.6-0.8MPa Control: PLC+touch screen Applicable liquids: juice, sauce, grease, etc.

What is Automatic Liquid Sachet Packing Machine?

Automatic Liquid Sachet Packing Machine has the functions of automatic metering, bag making, filling, sealing, cutting, etc. Its working principle is to form a packaging bag through a film coil, accurately meter the filling liquid and heat seal it, and finally output independent small bag packaging. The equipment can handle liquid materials with a viscosity range from low viscosity (such as drinking water, milk) to high viscosity (such as ketchup, peanut butter), and is compatible with composite film materials such as polyethylene (PE) and polypropylene (PP). The packaging speed is generally 30-100 bags/minute, and the metering accuracy error is controlled between ±0.2%-3%. The price is usually between US$650-8000.

Automatic Liquid Sachet Packing Machine can pack a variety of bag styles, three-side sealed liquid bags, back-sealed bags are convenient for stacking on the assembly line, special-shaped bags meet brand differentiation needs; continuous bag type bags are suitable for promotional combination packaging, etc.

Advantages of Automatic Liquid Sachet Packing Machine

Compared with the traditional manual filling and sealing method, Automatic Liquid Sachet Packing Machine has many advantages. It uses high-precision metering pumps or peristaltic pumps to achieve high-precision filling, and the error can be controlled within ±1%, ensuring that the liquid content of each bag is consistent; the whole process from bag making to finished product output is automated, with a high degree of automation, reducing manual intervention and improving production efficiency; it can adapt to packaging materials of different specifications (such as PE, PET/AL/PE composite film, etc.), and supports a variety of bag types (such as back seal, three-side seal, four-side seal, etc.), with strong flexibility; it uses stainless steel materials and closed filling systems, meets GMP standards, is hygienic and safe, and is suitable for food, medicine and other industries; and the equipment is simple to operate, the PLC control system and the human-machine interface touch screen make it easy for operators to get started, the packaging consistency is good, the error is small, and material waste is greatly reduced.

What are the functions of Automatic Liquid Sachet Packing Machine?

Automatic Liquid Sachet Packing Machine has multiple functions: in terms of automatic metering, it uses a high-precision flow meter or plunger pump to ensure that the amount of each bag is consistent; when making bags automatically, it can automatically complete the entire bag-making process starting from the film roll; its filling system can flexibly select different pump types according to different materials, such as gear pumps, plunger pumps, peristaltic pumps, etc.; in the heat sealing process, the horizontal and vertical heat sealing devices can ensure that the seal is firm and leak-proof; the automatic bag cutting function can set the cutting position and form according to needs, such as sawtooth cutting and straight cutting; the intelligent control system is equipped with PLC control and touch panel, which is convenient for parameter setting and has complete alarm and fault self-diagnosis functions; date coding can integrate coding equipment to realize automatic printing of production date; and it is also compatible with a variety of film materials, supporting composite film materials such as PET/PE, NY/PE, OPP/PE, etc.

Parameters of Automatic Liquid Sachet Packing Machine

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Price range of Automatic Liquid Sachet Packing Machine

Automatic Liquid Sachet Packing Machine provides three models: economical, standard and high-end, which are suitable for filling different volumes from 10ml to 1000ml and low to high viscosity liquids, support normal temperature or heated filling, meet the needs from basic manual operation to efficient automated production and export, and the price ranges from 1,400 to 9,500 US dollars. The economical model adopts basic PLC control, supports manual parameter adjustment and single nozzle filling, with an output of 20-30 bags/minute, suitable for 10-50ml small volume packaging (such as seasoning oil, jam), mainly handles low viscosity liquids (juice, emulsion), and requires normal temperature filling. Price 1,400-3,500 US dollars.

The standard model is equipped with automatic deviation correction and date printing functions, optional dual nozzles, supports 50-100ml specifications, and has an output of 40-60 bags/minute. It is suitable for medium-sized production lines (honey, shampoo), can handle medium and high viscosity fluids (pastes, syrups), and supports heated filling. The price range is US$4,000-5,500. The high-end model integrates visual inspection, multi-language interface, is compatible with 1000ml large-capacity packaging, has an output of 80-120 bags/minute, meets export needs (disinfectant, industrial grease), and can handle corrosive or high-temperature liquids (special material nozzles are required). The price is around US$6,000-9,500.

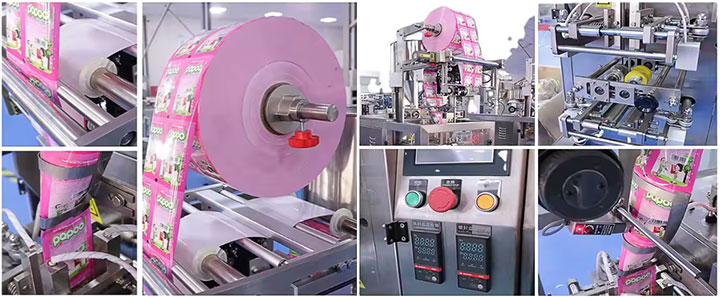

Automatic Liquid Sachet Packing Machine Packaging Samples

Applications of Automatic Liquid Sachet Packing Machine

Automatic Liquid Sachet Packing Machine has a wide range of applications, and is involved in many industries. Specifically, it can be used to package condiments (such as soy sauce, vinegar, chili sauce), honey, jam, beverage concentrate, etc. in the food industry; it can be used to package shampoo, shower gel, laundry detergent, conditioner and other one-time trial packs in the daily chemical industry; it can be used to package oral liquid, medicinal nutrient solution, disinfectant and other small doses in the pharmaceutical industry; it is suitable for packaging lubricants, experimental liquid samples, preservatives, etc. in the chemical industry; it can be used for packaging liquid fertilizers, pesticides, water-soluble vitamin liquids, etc. in the agricultural product field.