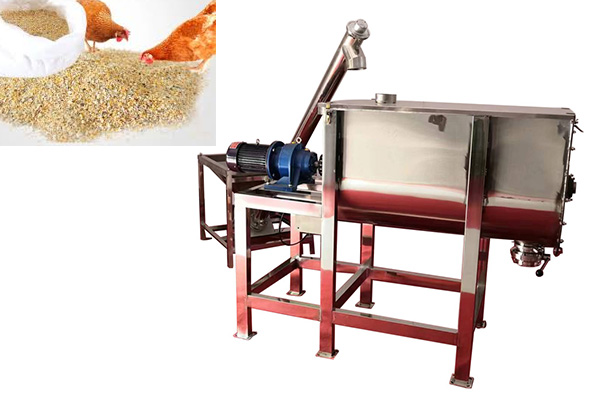

Poultry farm chicken feed mixer

The stirring device can evenly mix powder and granular chicken feed. It can also be used for solid-liquid mixing to meet the feed needs of chickens at different stages. The price is $700.00-$7,500.00/set

Mixing capacity: 100-6000 kg

Mixing time: 8-20 minutes

Capacity: Up to 1000 liters

Mixing speed: 15-60 rpm

Material: Carbon steel, stainless steel

What is a poultry farm chicken feed mixer?

A poultry farm chicken feed mixer is a mixer used to process chicken feed on farms. This mixer mechanically blends various chicken feed ingredients to ensure a balanced nutritional intake for the flock. It can quickly mix dry powders, grains (corn, wheat, soybean meal), trace elements, and oils. It is commonly used in small and medium-sized chicken farms and feed processing plants to produce premixes, concentrates, and complete feeds. Each batch can mix 100-6000 kg, and the mixing time is within 20 minutes (adjustable depending on the ingredients).

Poultry farm chicken feed mixers are available in carbon steel (affordable) or stainless steel (corrosion-resistant and easy to clean). The blades are made entirely of stainless steel for enhanced durability. Capacities are generally under 500 kg for small farms, and under 1000 kg for large farms.

What types of poultry farm chicken feed mixers are there?

Poultry farm chicken feed mixers primarily include vertical, horizontal, V-shaped, and integrated grinder-mixer models. Choose the appropriate model based on the chicken feed ingredients you need to mix. We can also provide customized mixing solutions and products tailored to your needs.

Vertical poultry farm chicken feed mixer: Utilizing a vertical spiral lift structure, the material is dispersed in an umbrella-like pattern, achieving 360° circulation mixing. This mixer is particularly suitable for mixing trace additives with a dosage of less than 5%. Occupying only 2-3 square meters, it can be used for small- to medium-sized farms to mix energy feeds such as cornmeal and bran, protein feeds such as soybean meal and fish meal, and vitamin premixes in small batches. The mixer can mix 500-2000 kg/batch, achieving a mixing uniformity of over 92%.

Horizontal Poultry Farm Chicken Feed Mixer: It utilizes a counter-rotating twin-ribbon design to create convection mixing. It can process wet feeds with a moisture content of 15%, making it suitable for complete feed production in layer farms. It can be used to mix pellets with powdered feed, blend forages containing crude fiber, and mix wet feed with dry powder. The mixing capacity ranges from 2-5 tons per batch.

V-Type Poultry Farm Chicken Feed Mixer: The V-shaped barrel structure uses a rotating motion to continuously divide and combine materials, achieving gentle yet efficient mixing. It is particularly suitable for materials requiring high uniformity. It is often used for evenly mixing dry powdered or granular materials with good flowability, such as vitamins, additives, premixes, trace elements, and other trace ingredients.

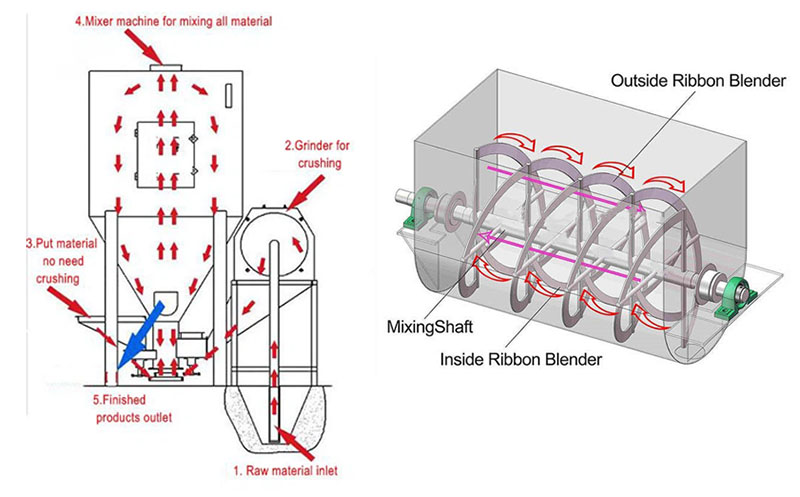

Combined Grinding and Mixing Poultry Farm Chicken Feed Mixer: Combining hammer milling and vertical mixing functions, corn and other grains are directly fed into the mixing stage after grinding, reducing raw material transfer losses. This mixer is suitable for grains that require on-site grinding and homemade mixed feed. It is often used for home-made broiler starter feed on family farms, achieving a one-stop process from raw material to finished product.

What are the advantages of a poultry farm chicken feed mixer?

A poultry farm chicken feed mixer quickly and evenly mixes chicken feed ingredients, ensuring a uniform distribution of all ingredients. This prevents picky eating and uneven intake by chickens, reduces feed waste, and lowers farming costs. Compared to manual mixing, the mixer delivers more uniform mixing and a 4-6 times improvement in efficiency. Based on a daily feed production of 2 tons, this saves over 30,000 yuan in labor costs annually. Liquid or trace ingredients such as oils, vitamins, and medications can also be added to the feed as needed to meet the specific nutritional needs of chickens at different growth stages.

What are the applications of a poultry farm chicken feed mixer?

A poultry farm chicken feed mixer can process a variety of chicken feed types, including powdered, granular, and solid-liquid forms, to meet the specific growth stages and nutritional needs:

Complete powdered feed: Suitable for mixing complete feed for various poultry species. It can evenly blend ingredients such as corn, soybean meal, wheat bran, and premixes to ensure nutritional balance. The V-shaped poultry farm chicken feed mixer is particularly suitable for evenly mixing dry powdered or granular materials with good flowability. Crushed Pellet Feed: For pelletized feeds like corn, wheat, and sorghum that require crushing, a blender can be used in conjunction with a grinder to crush first and then mix to ensure uniform feed particle size.

Liquid-Added Feed: A multifunctional chicken feed mixer equipped with a spray system allows for the addition of water, oil, honey, or other liquid additives to improve feed palatability and nutritional value. A metering pump precisely controls the amount of liquid added to ensure uniform mixing.

Medicinal and Therapeutic Feed: Medications and treatments can be evenly mixed to ensure each feed contains the correct dosage, avoiding inadequate or excessive drug efficacy due to uneven mixing. Poultry farm-specific feed mixers feature a PTFE non-stick coating to prevent drug adhesion.

Specialty Nutrition Feed: For breeder hens, chicks, or high-yielding laying hens requiring specialized nutrition, a variety of ingredients and additives can be precisely proportioned to meet specific nutritional needs. Stainless steel flat-top blenders are suitable for mixing grains and additives.

How do different types of poultry farm chicken feed mixers work?

When a poultry farm chicken feed mixer is operating, after the feed ingredients enter the machine, the mixing device primarily mixes the various ingredients of the chicken feed evenly. So how do vertical and horizontal models work?

Vertical chicken feed mixer: During operation, the chicken feed ingredients enter through the inlet and are lifted upward by the vertical screw conveyor inside the machine. After reaching the top, the chicken feed ingredients fly in an umbrella-like shape, falling from the sides of the mixing barrel, and then re-enter the conveyor through the gap at the bottom. This cycle repeats until they are evenly mixed and discharged from the discharge port.

Horizontal chicken feed mixer: As the twin helical blades rotate, the chicken feed ingredients undergo multi-directional, compound motion (axial and radial) within the mixing chamber. Driven by the blades, the chicken feed ingredients penetrate, shear, and diffuse, achieving rapid and uniform mixing in a short period of time.

Poultry farm chicken feed mixer specifications

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Poultry farm chicken feed mixer customer cases

| Customer Type | Application Scenario | Mixed Materials | Equipment Type | Mixing Volume (per Batch) | Mixing Time | Equipment Material |

| A Small-Scale Layer Farm in China (500 Chickens) | Daily Basic Feed Preparation for Layer Chickens, Once Daily | 60% Corn Flour, Soybean Meal 25%, stone powder 8%, premix 7% | Small horizontal mixer (0.2m²) | 150kg | 3-4 minutes | Contacting parts: 304 stainless steel, body: carbon steel |

| Medium-sized standardized broiler farm in Southeast Asia (10,000 birds) | High-energy feed mix for broiler fattening, twice daily | 70% corn, 5% bran, 20% soybean meal, 3% vegetable oil, 2% premix | Medium-sized horizontal mixer (0.8m²) | 800kg | 4-5 minutes | Entire machine constructed of 304 stainless steel |

| Large-scale laying hen farm in Vietnam (50,000 birds) | Mass production of complete feed for laying hens during the laying period, three times daily | 65% corn, 22% soybean meal, 10% shell powder, 2% premix, 1% enzyme | Large horizontal mixer (2.5m²) | 2000kg | 3-4 minutes | Contact parts constructed of 316 stainless steel, carbon steel body spray-coated |

| Specialty free-range chicken farm in India (2,000 birds) | Eco-friendly free-range chicken feed mix, 1 daily | Corn 55%, soybean meal 20%, mugwort powder 10%, pumpkin seed meal 10%, premix 5% | Vertical economical mixer (0.3m²) | 300kg | 12-15 minutes | Material contact parts: 304 stainless steel, body: carbon steel |

Poultry farm chicken feed mixer FAQs

How long does it take to mix chicken feed in a poultry farm?

Mixing times vary depending on the machine model and capacity: Vertical mixers require 10-20 minutes per batch, while horizontal mixers are more efficient, taking only 3-6 minutes per batch. V-type mixers take approximately 6-8 minutes per batch.

Does a longer mixing time result in a more uniform mix?

No. The optimal mixing time for general powders is 8-12 minutes. Mixing for more than 15 minutes may cause the material to segregate. For fiber-containing feeds, a mixing time of 10-15 minutes is recommended.