Convenient Vertical crushing and mixed machine

This machine simultaneously crushes and mixes materials, providing rapid mixing and improved production efficiency. Price range: $200.00-$2,500.00.

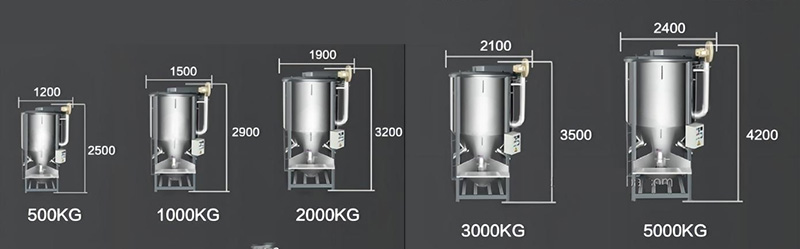

Mixed capacity: 100-5000 kg

Mixing time: 5-20 minutes

Mixer speed: 115-60 rpm

Crushing power: 11-15 kW

Mixing power: 3-5 kW

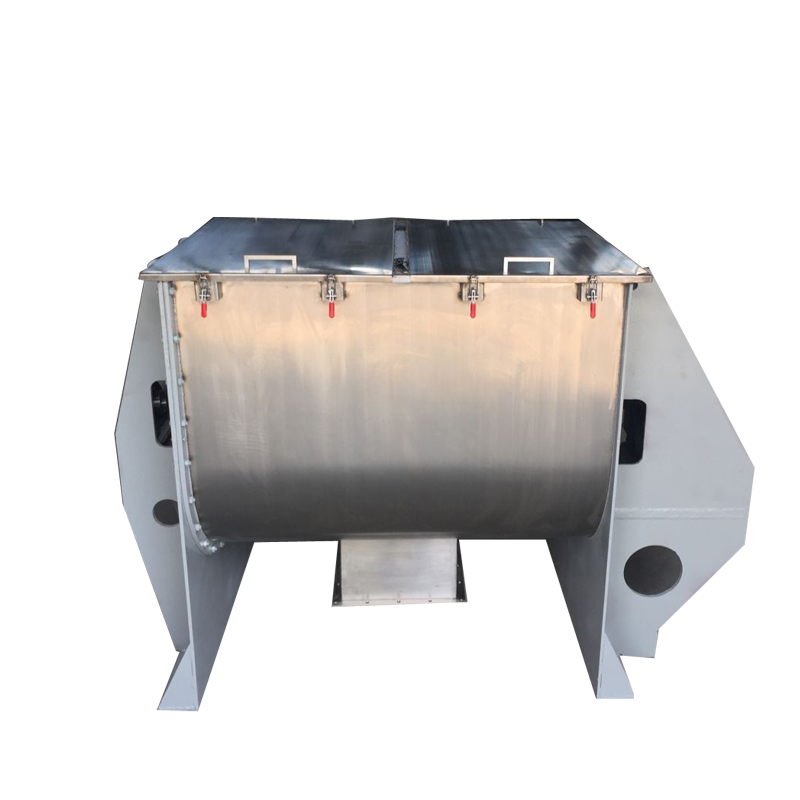

Material: Stainless steel, carbon steel

What is a Convenient Vertical Crushing and Mixing Machine?

A Convenient Vertical Crushing and Mixing Machine is a vertical mixer that combines material crushing and mixing. Its built-in crushing unit first breaks down lumps, and then the mixing unit achieves uniform mixing. This simultaneous crushing and mixing process eliminates the need for separate operations, improving crushing and mixing efficiency. It is commonly used for crushing and mixing granular materials, powders, and small, lumpy materials, such as plastic pellets, flour, cement, and feed ingredients. The mixing volume per batch ranges from 50 liters to 5,000 liters, and the mixing time varies from 5 to 20 minutes, depending on the material being crushed or mixed.

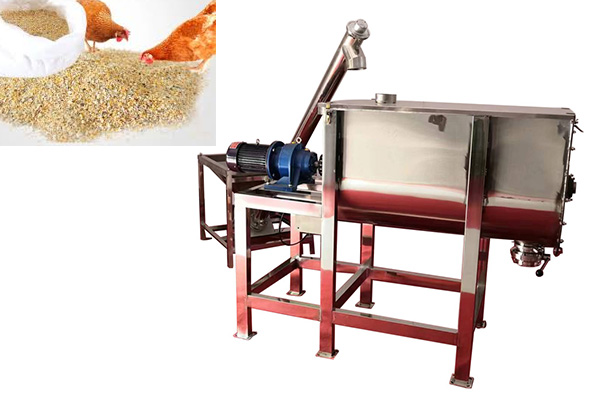

Combining vertical lifting, a mixing bin, and horizontal conveying, the Convenient Vertical Crushing and Mixing Machine can handle a variety of materials, including corn, wheat, rice, oats, sorghum, soybean meal, and other grains. It can produce various feed types, including premixes, concentrates, and complete powders. It is commonly used by rural livestock farmers, small farms, and small- to medium-sized compound feed plants. Available materials include carbon steel (suitable for non-corrosive, dry materials) and stainless steel (corrosion-resistant and easy to clean).

What types of Convenient Vertical Crushing and Mixing Machines are available?

Convenient Vertical Crushing and Mixing Machines are available in two types: carbon steel and stainless steel, depending on the material being crushed and mixed. Users can choose based on the material properties and application scenario.

| Characteristics | Carbon Steel Convenient Vertical Crushing and Mixing Machine | Stainless Steel Convenient Vertical Crushing and Mixing Machine |

| Applicable Material Types | Medium Hardness, Non-Corrosive Materials | Corrosive materials, materials with high hygiene requirements (such as food and pharmaceutical intermediates), general granular and powdered materials. |

| For example: agricultural materials such as corn and straw, common minerals, and common plastic granules. | For example: chemical raw materials, food raw materials, pharmaceutical intermediates, and materials that are moist or require specific hygiene. | |

| Main Features | Low price, good strength and toughness. | High corrosion resistance, easy to clean, low adhesion, and high hygiene. |

| Wear resistance | Good, but rapid wear with long-term handling of high-hardness materials. | Generally good, depending on the stainless steel grade (e.g., 304 and 316L offer better wear and corrosion resistance) |

| Maintenance and Lifespan | Susceptible to rust in humid or corrosive environments, potentially shortening lifespan and requiring more frequent component replacement | Longer service life in corrosive environments, requiring relatively low maintenance |

| Hygiene | Generally good, not suitable for industries with strict hygiene requirements such as food and pharmaceuticals | High, smooth surface, not prone to residue, meets hygiene standards for industries such as food and pharmaceuticals |

| Typical Applications | Small and medium-sized farms, feed processing, and budget-constrained applications with low corrosion and hygiene requirements | Food processing, chemical industry, pharmaceutical industry, corrosive environments, or places with high hygiene and cleanliness requirements |

What are the applications of the Convenient Vertical Crushing and Mixing Machine?

The Convenient Vertical Crushing and Mixing Machine can be used to crush and mix powders, granules, and bulk materials. It is commonly used in industries such as feed, food, pharmaceuticals, chemicals, agriculture, and fertilizer production:

Feed Industry: It can crush and mix various feed ingredients, including corn, soybean meal, bran, wheat, and premixes, easily processing both granular and powdered materials.

Chemical Industry: It is suitable for crushing and mixing materials such as plastic granules, chemical raw materials, and additives, including some with a certain degree of stickiness or hardness.

Agriculture: For biomass energy companies, it can process raw materials such as straw and sawdust. In fertilizer production, it can crush and mix various fertilizer raw materials to improve fertilizer quality and efficiency.

Fertilizer Manufacturing: In compound fertilizer production, it crushes and mixes various fertilizer raw materials such as nitrogen, phosphorus, and potassium, as well as trace elements, to produce a nutrient-balanced compound fertilizer. The Convenient Vertical Crushing and Mixing Machine ensures uniform mixing of fertilizer raw materials, improving fertilizer efficiency and market competitiveness.

What are the advantages of a Convenient Vertical Crushing and Mixing Machine?

The Convenient Vertical Crushing and Mixing Machine's vertical structure streamlines the material's movement path within the machine, shortening the crushing and mixing time. For example, in feed production, compared to traditional split-type equipment, this can reduce mixing time from 20-30 minutes to 5-15 minutes, significantly improving production efficiency. Furthermore, the integrated design reduces energy loss between equipment and lowers energy consumption.

The Convenient Vertical Crushing and Mixing Machine performs mixing and crushing simultaneously, ensuring that the material is thoroughly tumbled and collided within the machine. For example, in feed production, it can ensure a mixing uniformity (CV value) of ≤5% for various raw materials such as corn, soybean meal, and premixes, meeting the refined feeding requirements of livestock, poultry, and aquatic products, while ensuring consistent product quality.

How does a Convenient Vertical Crushing and Mixing Machine work?

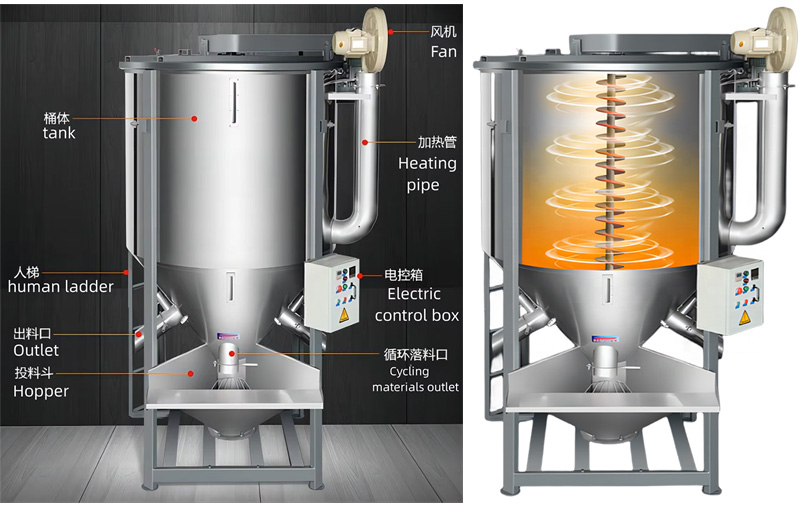

The Convenient Vertical Crushing and Mixing Machine primarily operates through crushing and mixing.

Crushing Principle: After the material enters the crushing chamber from the feed inlet, it is gradually crushed by the impact of the high-speed rotating hammers and the friction of the screen plates. Centrifugal force and airflow cause the material to be discharged through the bottom outlet.

Mixing Principle: The crushed material enters the mixing chamber, where it is transported vertically upward by the spiral agitator. Upon reaching the top, it is ejected, then slides back down the inner wall of the chamber and is lifted up again. This cycle repeats repeatedly to achieve uniform mixing.

Convenient Vertical Crushing and Mixing Machine Specifications

| Model | Speed | Power | Dimension | Diameter x Height |

| 50 KG | 40 RPM | 0.75 KW | 800*780*980 | 780*420 |

| 75KG | 40 RPM | 1.5KW | 950*900*980 | 900*420 |

| 100 KG | 40 RPM | 1.5 KW | 1050*1000*980 | 1000*420 |

| 150 KG | 40 RPM | 2.2 KW | 1150*1100*980 | 1100*420 |

| 200 KG | 40 RPM | 3 KW | 1250*1200*1080 | 1200*490 |

| 250 KG | 40 RPM | 4 KW | 1350*1300*1100 | 1300*490 |

| 400 KG | 40 RPM | 5.5 KW | 1450*1400*1300 | 1400*560 |

| 500 KG | 40 RPM | 7.5 KW | 1550*1500*1400 | 1500*560 |

Convenient Vertical Crushing and Mixing Machine Case