Spices ribbon mixer

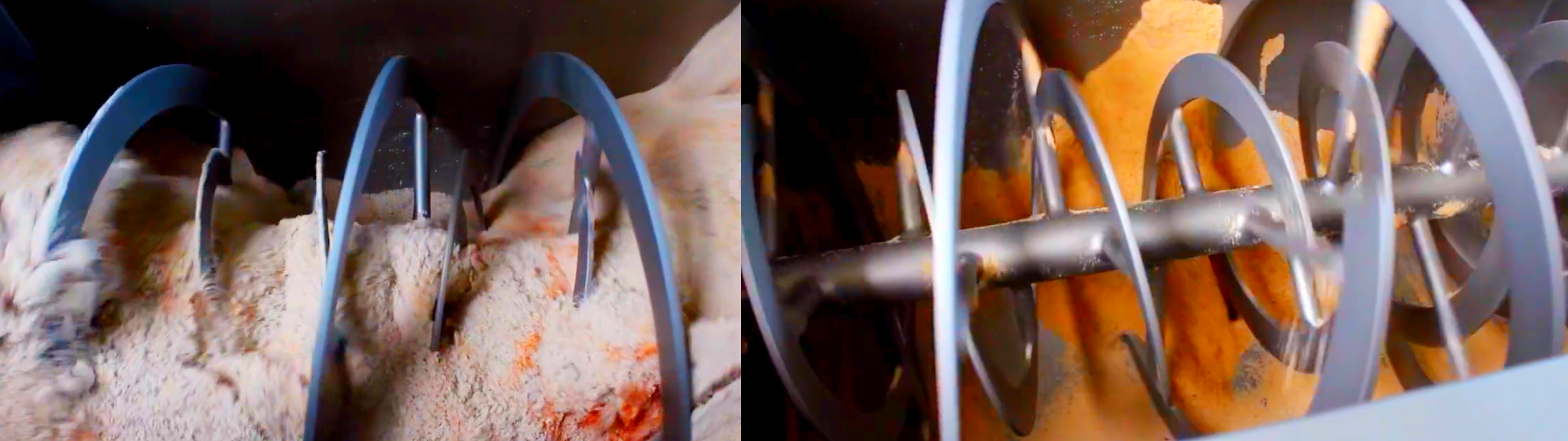

Due to the aromatic nature, fine proportioning, moisture absorption or adhesion of spices, the screw belt mixer can gently stir during operation to avoid high shear causing the volatilization of aromatic substances or particle damage, thereby maintaining the original flavor and functional characteristics of spices.

Applicable materials: powders, powders and liquids, low viscosity materials

Mixing time: relatively short (3-10 minutes/batch)

Discharge method: Bottom central opening, fast discharge

Applicable industries: food (such as spices), chemical industry, pharmaceutical chemical industry, pharmaceuticals, cosmetics (high viscosity materials)

Product description

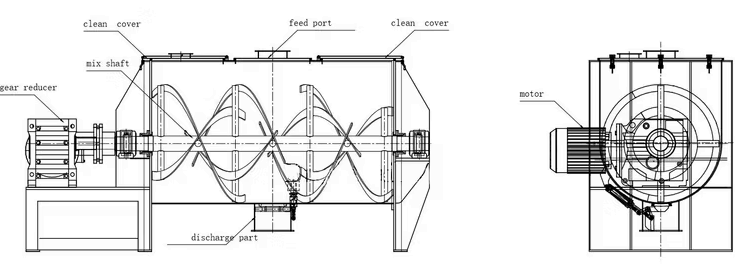

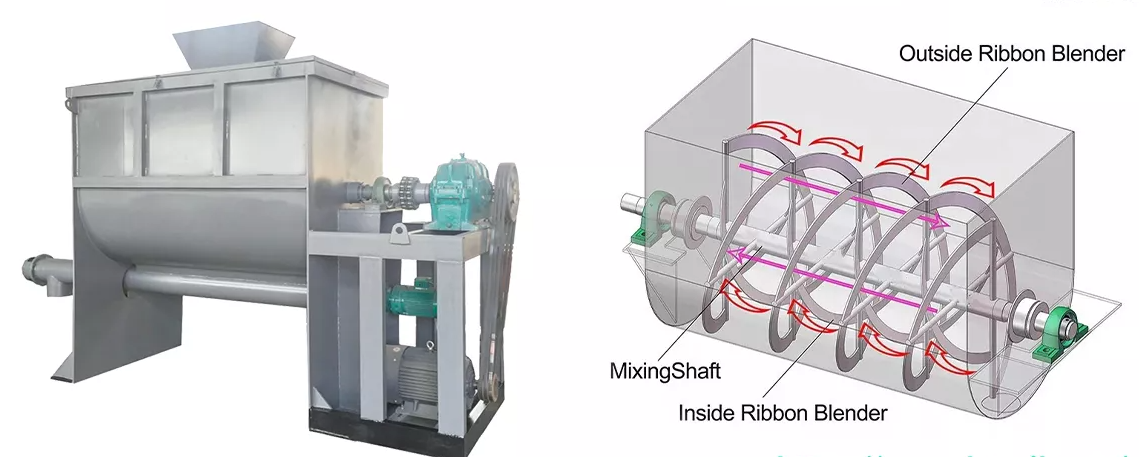

Spices ribbon mixer is an efficient mixing device designed specifically for blending spices. It usually adopts a U-shaped horizontal tank and a double-layer or multi-layer spiral belt agitator installed horizontally inside. Its working principle is unique: the outer spiral belt pushes the spice from both ends to the center, while the inner spiral belt pushes the material from the center to both ends, forming a three-dimensional convective mixing.

Considering the characteristics of spices, such as their volatility, hygroscopicity, or tendency to clump, a ribbon mixer can mix them gently and thoroughly, avoiding the loss of effective ingredients while ensuring that the powder is not excessively ground or clumped.

The mixed spices are evenly distributed, which can fully exert their complex flavor and coloring effect, thus meeting the strict requirements of high standard mixing degree for spice products in industries such as food and medicine. Its high efficiency and energy-saving characteristics also make it an indispensable key equipment in spice production.

What are the main functions of a spices ribbon mixer

The spices ribbon mixer is a device suitable for mixing powdered or granular spice materials, including seasoning powders such as thirteen spice, five spice, pepper, cumin powder, etc; Compound spice (composed of multiple powders mixed in proportion); Food additives (such as essence carrier, anti caking agent, etc.); Dry powder of traditional Chinese medicine or herbal extract powder; Powder materials with low moisture content and good flowability are not suitable for materials with high moisture content, easy agglomeration, and strong moisture absorption.

① Uniform mixing: uniformly mixing various powders or granular materials

② High uniformity: allows the spices to be fully mixed in a short period of time, usually reaching over 98%

The difference between horizontal and vertical spices ribbon mixers

|

Project |

Horizontal ribbon mixer |

Vertical ribbon mixer |

|

Image |

|

|

|

Structural form |

U-shaped horizontal cylinder, the ribbon is arranged in the horizontal direction |

Cylinder vertical structure, the ribbon is arranged in a spiral ascending shape |

|

Material flow mode |

Inner and outer ribbons push in opposite directions, and the material performs axial and radial convection motion |

The ribbon is lifted upward by the spiral, and falls naturally by gravity to form a cycle |

|

Mixing speed |

Fast, generally 5-10 minutes to complete mixing |

Relatively slow, about 10-20 minutes |

|

Mixing uniformity |

High (CV≤5%), suitable for spice formulas with high ratio requirements |

Medium (CV≤8%), suitable for materials with low mixing requirements |

|

Applicable materials |

Powder, fine granular spices, mixtures with large proportion differences |

Powders or small particles with good fluidity and similar density |

|

Application scenario examples |

High-end compound seasonings, powder premixes, flavor and fragrance additives, etc. |

Ordinary powder mixing, coarse-grained seasoning mixing, feed spice mixing |

Characteristics of spices ribbon mixer

High mixing uniformity: suitable for uniform distribution of small proportion components (such as 1:1000), smooth operation of the screw belt, suitable for powders that are fragile or contain aromatic components

Low energy consumption and low crushing: Equipment design focuses on low energy consumption and low material crushing rate to ensure that the quality of spices and other materials is not compromised.

Anti adhesion effect: Some screw belt mixers have anti adhesion function, suitable for mixing high viscosity or powdery materials, reducing material residue.

Multifunctionality: It can achieve uniform mixing within 10-30 minutes, with a mixing uniformity of over 98%, and can handle powders, particles, and slightly viscous materials

Common model parameters of spices ribbon mixer

|

Model |

Total volume (L) |

Loading capacity (L) |

Motor power (kW) |

Mixing time (min) |

Dimensions (mm) |

|

LD-300 |

300 |

120-180 |

3.0 |

5-8 |

1800×800×1300 |

|

LD-500 |

500 |

200-300 |

4.0 |

5-8 |

2200×950×1400 |

|

LD-1000 |

1000 |

400-600 |

5.5 |

5-10 |

2600×1200×1600 |

|

LD-2000 |

2000 |

800-1200 |

7.5-11 |

5-10 |

3200×1400×1800 |

How does the spices ribbon mixer work

When the spices ribbon mixer is working, the motor drives the ribbon mixer to rotate through the transmission device. The spiral blades of the ribbon mixer push the spice material to move axially and flip radially inside the mixing tank, creating complex convective motion of the material inside the tank.

The inner spiral belt pushes the material near the mixing shaft outward, while the outer spiral belt gathers the material near the tank wall towards the center. Under the action of the inner and outer spiral belts, the material continuously exchanges and mixes up and down, inside and outside, thereby achieving uniform mixing.

Parts display of spices ribbon mixer

Mixing tank: usually made of stainless steel material, it can ensure that the spices are not affected by the external environment during the mixing process

Spiral belt mixer: generally composed of two layers of spiral blades inside and outside, it is the core component of the mixer.

① The inner spiral pushes the material outward

② The outer spiral gathers the material towards the center

③ Realize bidirectional convection during the stirring process

Transmission device: responsible for driving the rotation of the mixer, usually using high-performance motors and reducers

Feeding and discharging device: convenient for material feeding and removal, the feeding port is generally located at the top of the mixing tank, and the discharging port is located at the bottom

What can spices ribbon mixers be used for

The spice snail belt mixer is an efficient mixing equipment, which is widely used in food, condiment, essence and spice industries, especially for the uniform mixing of powder, granular or trace additives.

In spice processing, this equipment can be used for thorough mixing and homogenization of various composite seasonings and spice powders (such as pepper powder, turmeric powder, chili powder, etc.), ensuring that all raw materials are fully blended and evenly distributed, and improving the consistency of product flavor. For example, in the production process of curry powder, five spice powder, brine packs and other products, the spices ribbon mixer can effectively avoid problems such as material layering and agglomeration, improve mixing accuracy and production efficiency.

How efficient is the spices ribbon mixer?

Taking the horizontal screw belt mixer as an example, when processing 1000kg of spices, the time to complete uniform mixing is usually 10-15 minutes, while a regular mixer of the same capacity may take 20-30 minutes.