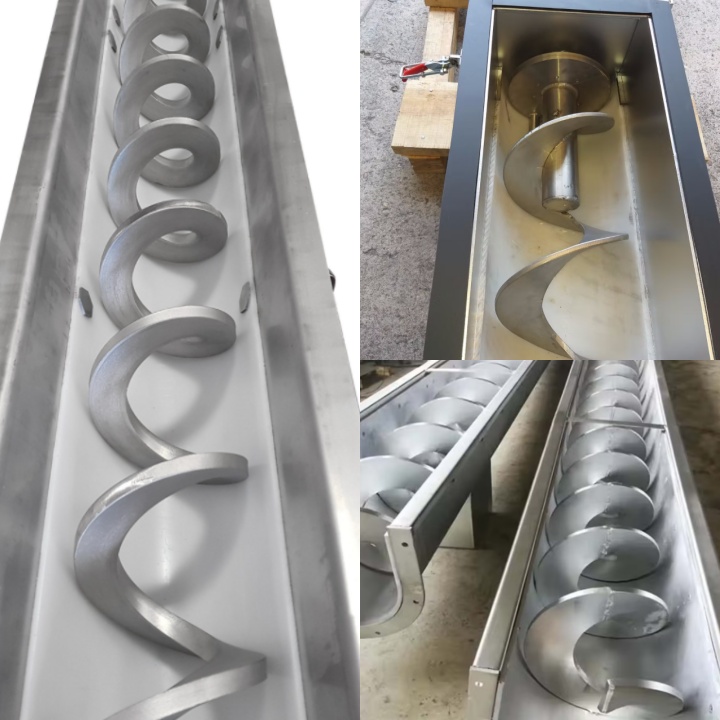

stainless screw conveyor

The price of stainless screw conveyors varies depending on its type, conveying capacity and customization requirements. Its price ranges from$100 to $5,000.

Rotation speed: 45-70 R/Min

Stainless steel: 201, 304, 316

Frame material: carbon steel/stainless steel

Power: 0.4kW-22kW

Voltage: 220V/380V/415V

Frequency: 50/60Hz

What is a stainless screw conveyor?

stainless screw conveyor is a common bulk material conveying equipment. This type of equipment can be divided into two common types according to the structural form: U-shaped trough type and tube type. It can also be designed as a single screw or double screw configuration according to specific uses. The design of stainless steel screw conveyor can achieve the processing of several cubic meters to tens of cubic meters of materials per hour. The specific processing capacity depends on the screw diameter, speed and material characteristics. Its conveying distance is usually in the range of several meters to tens of meters, which can meet the material transfer needs between different equipment in the factory. This equipment is mainly used in specific production links with strict requirements on hygiene, corrosion prevention or cleanliness.

What are the types of stainless steel screw conveyors?

Stainless steel screw conveyors are essential equipment for handling powders, granules, bulk, and sticky materials. Conveyor types, ranging from open U-troughs and fully enclosed tubulars to designs with and without a central shaft, each offer unique features tailored to suit varying material properties, conveying environments, and process requirements. These design differences result in distinct advantages in cleanability, sealing, anti-entanglement, and adaptability.

Features: It adopts a U-shaped open trough, which is easy to clean and maintain, and has a relatively simple structure.

Application: It is mainly used for horizontal or small inclination (usually less than 20°) material transportation. It is suitable for powdered or granular materials with strict requirements on residues.

Features: It adopts a fully enclosed circular tube shell to achieve completely closed transportation, effectively preventing dust leakage and external pollution.

Application: It is suitable for occasions with high environmental requirements, toxic and harmful, volatile or need to maintain material cleanliness, such as conveying materials with strict dust control, and can also be used for inclined or vertical transportation.

Features: The spiral blades are welded on the central shaft, and the blades are driven to push the material through the rotation of the central shaft. The structure is stable and suitable for conveying materials with good fluidity, non-sticky or not very sticky.

Application: conveying most conventional powdery and granular materials, such as flour, starch, sugar, granular chemical raw materials, etc.

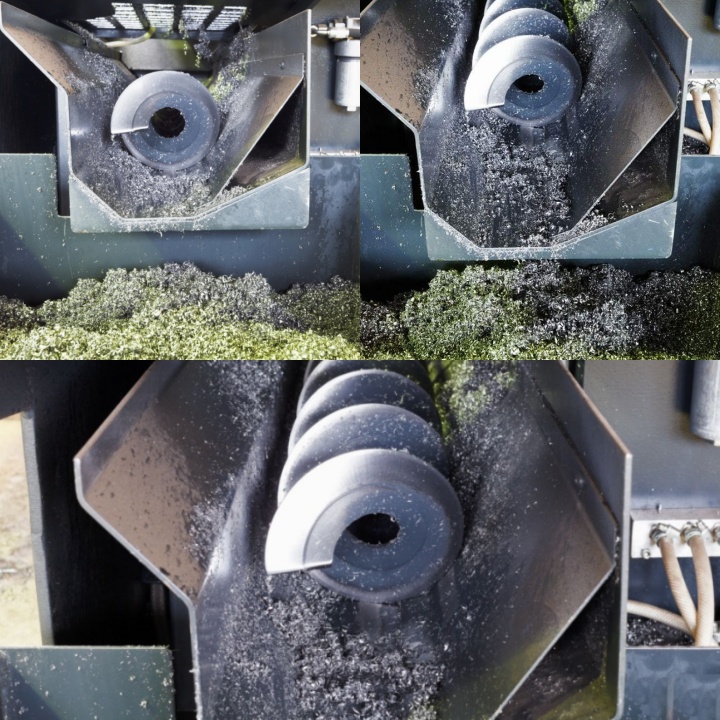

Features: The spiral blade has no central shaft, but conveys materials through a flexible spiral body wrapped in the trough. The design without a central shaft avoids the material from winding or clogging on the shaft, and is especially suitable for conveying materials with strong viscosity, easy winding, block or fiber.

Application: sludge, garbage, wet residue, fibrous materials, high-viscosity paste materials, etc., which are common in sewage treatment, food waste treatment and other fields.

Basic parameters of stainless screw conveyors

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the advantages of stainless screw conveyors?

Stainless steel screw conveyors are ideal for handling a wide range of bulk materials. Their strengths lie not only in their excellent resistance to corrosion and contamination, but also in their rugged construction and wide material compatibility, enabling them to meet the demands of conveying high-standard, high-purity materials.

Corrosion resistance: This is the core advantage of stainless steel. Stainless steel (such as 304, 316L, etc.) contains alloy elements such as chromium and nickel, which can form a dense passivation film on the surface, effectively resisting the corrosion of acid, alkali, salt solution and various organic and inorganic chemicals.

Avoid material contamination: Stainless steel material itself is stable in nature, will not release harmful substances into the conveyed material, and will not react chemically with the material. This ensures the purity of the material during the conveying process and avoids rust contamination or other impurities that may be caused by carbon steel equipment.

Strong structure and durability: Although the cost of stainless steel is higher than that of carbon steel, its high strength and toughness ensure the strong structure of the equipment. With sophisticated manufacturing technology, stainless screw conveyor can withstand continuous material loads and operating stress.

Wide adaptability: In addition to the versatility of traditional screw conveyors in conveying various types of powdered, granular, and small block materials, the addition of stainless steel enables it to be expanded to a wider range of material types, especially those materials that have special requirements for material purity, hygiene level, and corrosion resistance, such as polymers, fine pigments, condiments, and various additives.

What are the applications of stainless screw conveyors?

Stainless screw conveyors play a role in a variety of material handling scenarios, mainly used for continuous conveying of bulk materials, especially in those occasions where there are specific requirements for material purity, hygiene, or equipment corrosion resistance.

Handling corrosive materials: When the material itself is acidic, alkaline, or otherwise corrosive, stainless steel can resist erosion, extend the service life of the equipment, and ensure the stability of the conveying process.

Requirements for material purity: When the conveyed material cannot be contaminated by rust or other impurities, stainless screw conveyors are an important choice. It ensures that the material maintains its original purity throughout the conveying process.

Need to maintain hygiene and cleanliness: In scenarios that require frequent cleaning and disinfection, the smooth surface and corrosion resistance of the stainless screw conveyor make it easy to clean, help maintain a high standard of hygiene and avoid cross-contamination of materials.

Material conveying and grading: It can be used to convey powders, granules, and small pieces of materials from one processing unit to another, and can also assist in grading or mixing materials in some cases.

Adapt to complex space layout: The stainless screw conveyor can be installed horizontally, tilted or vertically according to the actual space and process requirements on site, and flexibly adapt to various material conveying paths.

Stainless Steel Screw Conveyor Case Studies

Stainless steel screw conveyors, with their unique advantages, have become key equipment for bulk material handling in various industrial processes. Their applications are extensive, particularly in sectors with stringent requirements for material purity and hygiene. In the food processing industry, stainless steel screw conveyors are indispensable. They are primarily used to transport various raw materials, such as flour, starch, sugar, cocoa powder, and coffee beans. Stainless steel's corrosion resistance and ease of cleaning effectively prevent contamination and ensure food safety. Whether conveying raw materials from silos to mixers or transferring materials between different stages of a production line, stainless steel screw conveyors provide a stable and reliable solution. They are also commonly used to transport finished products such as milk powder, grains, and condiments, ensuring that the materials are protected from environmental influences during transportation. Stainless steel screw conveyors also play an important role in agricultural production. For example, in feed processing plants, they are used to transport various grains, soybean meal, and additives. Stainless steel's durability allows it to withstand the abrasion of various materials and ensures feed hygiene. In seed processing, they are also commonly used to transport and mix seeds to prevent cross-contamination. Its fully enclosed design effectively prevents moisture and contamination during material conveying. In the chemical industry, stainless screw conveyors are primarily used to transport powders, granules, and chemical additives requiring high purity. For example, in the production of plastics, coatings, or fine chemicals, they ensure that materials do not react with the equipment during conveying, maintaining chemical stability. Furthermore, their robust structure can handle abrasive materials such as fine sand and quartz powder. When handling these mineral materials, the wear resistance of stainless steel significantly extends the equipment's service life and reduces maintenance costs.

What is the price of stainless screw conveyor?

Stainless screw conveyor is widely used in industries with strict requirements for hygiene and corrosion protection due to its excellent corrosion resistance, high cleanliness and easy maintenance. Its price range ranges from US$100 to US$5,000, which is determined by a variety of factors: material grade and surface treatment are the primary factors affecting the price of stainless screw conveyor. For example, there is a significant price difference between 304 stainless steel (food grade) and 316L stainless steel (higher corrosion resistance), and 316L is usually more expensive. The type of equipment and structural complexity also directly affect the price. U-trough structure is usually slightly cheaper than tubular structure because tubular conveyors require more precise processing and sealing. Conveying capacity and size are another key factor. The processing capacity of the equipment (volume or weight of material conveyed per hour) directly determines the diameter, length and required motor power of the screw. The type and accuracy of the spiral blades also affect the cost. Spiral blades come in various forms, such as solid, belt, paddle, etc. Blades with special shapes (such as variable pitch blades) or higher requirements for blade processing accuracy will increase manufacturing difficulty and cost. Finally, brand and service are also considerations. Well-known brands usually have more mature technology, stricter quality control and a more complete after-sales service network, and their product pricing will be relatively high. Customized requirements (such as special explosion-proof, high temperature resistance, ultra-high cleanliness, etc.) will also lead to additional design and manufacturing costs.

Stainless Screw Conveyor Manufacturers

Due to the diverse material properties, handling volumes, and installation environments across different industries, standardized stainless screw conveyors often fail to fully meet all requirements. Therefore, manufacturers with customization capabilities can provide more precise and adaptable solutions. Manufacturers can adjust the conveyor's length, width, conveying angle, and inlet and outlet locations based on the customer's site space. For example, in areas with limited space, more compact U-trough or tubular conveyors can be designed to accommodate narrow installation environments. In addition to standard 304 or 316 stainless steel, manufacturers can offer higher-grade specialty stainless steel materials based on the material's corrosiveness or hygiene requirements. Furthermore, for applications such as food or fine chemicals that require frequent cleaning, the equipment surface can be polished to achieve a higher level of hygiene and reduce material residue. Customization also involves adding or removing functions. For example, for materials that require heating or cooling, a jacketed structure can be designed around the spiral trough to allow steam or cold water to flow in. For materials prone to agglomeration, an agitator can be added. For applications requiring precise control of the conveying volume, a variable-frequency speed-regulating motor can be used. Manufacturers can recommend and manufacture shaftless or shafted screw conveyors based on material characteristics such as viscosity, fibrousness, or entanglement. Shaftless designs effectively address entanglement and blockage, while shafted designs are more suitable for conventional powders and granules with good flowability. Manufacturers with customization capabilities typically ensure that the final delivered equipment is compatible with the customer's production process through detailed requirements communication, on-site surveys, and design solutions.

The selection and configuration of the stainless screw conveyor is often based on the specific physical and chemical properties of the processed materials and the specific requirements for the processing environment. The application of stainless steel enables this type of conveyor to cope with corrosive media or occasions with strict cleanliness regulations. In the process of conveying materials, it realizes closed operation, which helps to maintain a clean environment in the workshop. Therefore, the stainless screw conveyor is a key equipment for the orderly movement and management of materials in the production line.