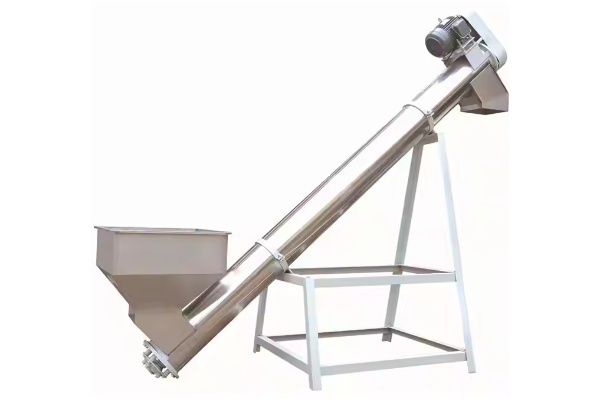

Vertical Screw Conveyors Price

Monday November-10 2025 13:41:51

Vertical Screw Conveyors are equipment used to lift materials vertically, and their price varies depending on a variety of factors. The price range for this type of equipment is wide, ranging from $400 to $5,000, and there's generally no fixed standard. Pricing is primarily influenced by a combination of factors, including material, size, performance specifications, and additional features. The material used directly determines the base cost. Regarding equipment specifications, conveying height, screw diameter, and handling capacity are key factors influencing price.

What are the types of vertical screw conveyors?

Vertical screw conveyors are equipment used to lift materials vertically. Depending on the material, they are primarily categorized into stainless steel and carbon steel. The choice of these two materials is a major factor influencing their price.

Stainless Steel Vertical Screw Conveyors

Material: Stainless steel (such as 304, 316, etc.)

Features: Stainless steel offers excellent corrosion and high-temperature resistance, as well as ease of cleaning. This makes it particularly suitable for industries requiring high hygiene standards. Price: Stainless steel vertical screw conveyors are significantly more expensive than carbon steel ones. The specific price depends on the stainless steel grade (304 is cheaper than 316), equipment size, processing technology, and surface treatment. Generally speaking, for the same specifications, stainless steel equipment can cost two to four times as much as carbon steel equipment, or even more.

Carbon Steel Vertical Screw Conveyor Price

Material: Carbon Steel

Features: Carbon steel offers high strength and wear resistance, and is inexpensive. However, its main disadvantage is its susceptibility to rust and poor corrosion resistance. Carbon steel equipment is typically painted to prevent rust.

Price: Carbon steel vertical screw conveyors are relatively inexpensive. They are more suitable for industries that don't require special hygiene or corrosion protection, such as construction, mining, and metallurgy. They are generally the lower of the two types, offering a high cost-effectiveness.

What Factors Affect the Price of Vertical Screw Conveyors?

The price of vertical screw conveyors is influenced by a variety of factors; pricing isn't determined by a single factor. Besides the significant differences caused by basic material choices (such as stainless steel versus carbon steel), the equipment's specific specifications, performance parameters, and additional features directly determine its final cost. These factors collectively constitute the decisive factors influencing equipment price. There are many factors influencing the price of vertical screw conveyors, which can be summarized as follows:

Material selection: This is the primary factor influencing price. The price of vertical screw conveyors is generally determined by the nature of the material being conveyed. Stainless steel is suitable for industries with strict hygiene and corrosion protection requirements, such as the food and chemical industries. Stainless steel (such as 304 and 316) is much more expensive than carbon steel and has higher processing costs. Carbon steel is less expensive and is suitable for industries with less stringent material requirements, such as mining, construction, and metallurgy.

Equipment Specifications and Dimensions: The physical dimensions of the equipment directly affect the amount of raw materials required and the manufacturing time, making it a key factor influencing price. Higher vertical heights require larger spiral blades, a larger barrel, and a larger motor, resulting in a higher price. Larger diameters of the spiral blades and barrel mean a larger single-pass conveying volume, which also increases the price.

Performance Parameters: Performance parameters to consider during design directly impact equipment configuration and cost. A higher conveying capacity (tons per hour) typically requires a more powerful motor, thicker spiral blades, and larger dimensions, resulting in higher costs. The choice of power depends on the density and volume of the material being conveyed. Higher power translates to higher prices. Different speed requirements may require different types of reducers, which in turn impacts price.

Additional Features and Configurations: To meet specific operational requirements, many vertical screw conveyors incorporate customized features, which increase costs. If the equipment requires height adjustment, the hydraulic system significantly increases costs. The addition of features such as automated control, remote monitoring, and variable frequency drive increases the equipment's technical content and price. Safety features such as emergency stop buttons, overload protectors, and anti-jam sensors are also recommended. If used in flammable or explosive environments, explosion-proof motors and related components are required, significantly increasing the price.

Vertical Screw Conveyors Price Solution

A feed mill needs to lift extruded feed pellets, heated to approximately 70-80℃, from the ground floor to the top of a 15-meter-high cooler for cooling. The required conveying capacity is 10 tons/hour, the material bulk density is approximately 0.6 tons/cubic meter, and the particle size is φ2-5mm. For this situation, Vertical Screw Conveyors Price approximately $9,000. Considering the slight corrosiveness of the material and for ease of cleaning, the screw blades and inner wall of the conveyor barrel will be rust-proofed. A 7.5 kW explosion-proof motor will be selected, and the inlet and outlet will be designed with flange connections for easy integration with upstream and downstream equipment.

Vertical Screw Conveyors Supplier

Macchrise, a supplier of conveyor equipment with many years of experience, offers competitive pricing for its Vertical Screw Conveyors. During equipment manufacturing, they provide selection advice or customization based on your needs, ensuring that the main body, drive unit, and other components meet production standards. Free sample testing with your materials is available to help you choose the appropriate model.

The price of a vertical screw conveyor is the result of the interaction of multiple practical factors. The material used, physical dimensions and load-bearing capacity of the equipment, and the configurations added to meet specific working conditions all contribute to its cost structure. In practice, these factors are often weighed against specific needs to select the appropriate equipment. Carbon steel equipment is generally priced lower due to its manufacturing costs. However, when equipment needs to handle food or corrosive materials, stainless steel becomes a necessary option, and its cost increases accordingly.