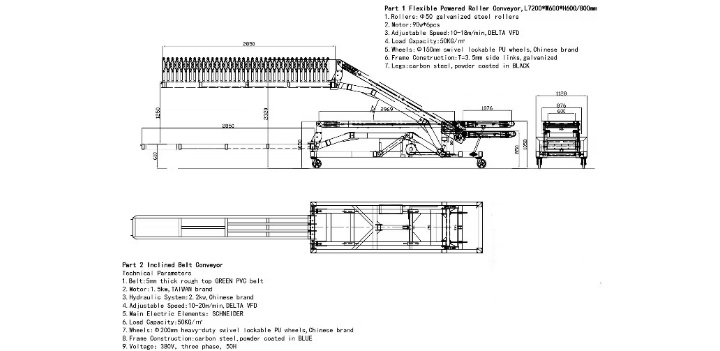

Truck Loading Unloading Belt Conveyor

Prices for truck loading unloading belt conveyors vary depending on factors such as model, features, conveying length, load capacity, ranging from $260 to $8,900 or even higher.

Motor for Conveyor:1.5kw

Motor for Up/Down:2.2kw

Load Capacity:50kg/m

Adjustable Height:700-2500(mm)

Variable Speed:10-20M/min

Frame:Carbon steel/Stainless steel

What is Truck Loading Unloading Belt Conveyor?

Truck Loading Unloading Belt Conveyor are commonly used in logistics and warehousing operations, designed to transfer goods between warehouse platforms and transport vehicles. These types of equipment can be categorized into various types based on their structure and application, including telescopic, mobile, and hydraulic. Each type is designed to meet specific loading and unloading requirements. Telescopic conveyors typically have a conveying distance of less than 20 meters and are suitable for the rapid loading and unloading of parcels and boxed goods. Mobile conveyors have a wheeled base, allowing for flexible movement within the work area. They typically have longer conveying distances and are suitable for multi-point cargo loading and unloading. Hydraulic conveyors, on the other hand, use a hydraulic system to adjust the height and angle of the conveyor belt to accommodate vehicles or work platforms of varying heights.

What are the types of truck loading unloading belt conveyors?

Truck loading unloading belt conveyors are essential equipment in logistics and warehousing systems. Based on their structure and functional characteristics, they are primarily categorized into three types: telescopic, mobile, and hydraulic. Each type offers distinct advantages in terms of material suitability, handling capacity, and conveying distance, adapting to diverse operational needs.

Telescopic Belt Conveyor

The telescopic truck loading unloading belt conveyor is a relatively common type. Its characteristic is that its body can be freely extended and retracted like a telescope, allowing the conveyor belt to extend directly into the truck bed, significantly reducing the distance required for manual handling.

Applicable Materials: It is suitable for a wide range of boxed, bagged, parcel, and small bulk cargo. Examples include express parcels, e-commerce products, food boxes, and cement bags. Because it can directly enter the truck bed, it is highly efficient for materials with regular shapes.

Capacity: It has a high throughput and high efficiency. By adjusting the conveyor belt speed and extension length, it can accommodate trucks of different sizes and types. By eliminating intermediate links, loading and unloading speeds are significantly higher than traditional methods.

Conveying Distance: It is primarily used for short-distance loading and unloading operations, typically from the warehouse platform to the truck bed. Its extension range generally ranges from a few meters to twenty meters, specifically designed to fill this "last meter" gap.

Mobile Belt Conveyor

Mobile conveyors are equipped with wheels, allowing for easy movement within the work area. It lacks telescopic functionality, but is highly flexible and can be adjusted to accommodate different loading and unloading locations or trucks.

Applicable Materials: Similar to telescopic conveyors, it can handle boxed, bagged, and bulk materials. However, due to its mobility, it is more commonly used in situations where frequent changes in loading and unloading locations are required, such as in large warehouses, ports, or bulk material yards, where multiple trucks or materials from different locations are loaded and unloaded.

Capacity: Moderate. While not as efficient as telescopic conveyors in the "last mile," its mobility allows it to serve a wider area. Adjustable height and angle can accommodate various loading and unloading heights.

Conveying Distance: Primarily used to transport materials from a fixed loading and unloading point to a truck, or vice versa. Its conveying distance is typically longer than that of a telescopic conveyor because it can function as a complete conveyor line, not just for reaching into a truck compartment.

Hydraulic Belt Conveyor

Hydraulic conveyors generally refer to conveyors whose lifting or angle adjustment is achieved through a hydraulic system. It may have both mobile and telescopic functions, but its core feature is its high height and angle adjustability, allowing it to easily accommodate truck beds or warehouse platforms of varying heights.

Applicable Materials: Suitable for materials that need to be loaded and unloaded at varying heights, such as loading high-box trucks or unloading materials onto stacks of varying heights. Its hydraulic lift function allows it to adapt to various height differences.

Handling Capacity: This depends on whether it has telescopic or mobile functions. Hydraulic lift alone won't significantly change handling capacity, but it will greatly improve loading and unloading convenience, indirectly boosting overall efficiency.

Conveying Distance: Conveying distance is primarily determined by its basic structure (mobile or telescopic). The hydraulic function primarily serves vertical height adjustment, not horizontal conveying distance.

What are the advantages of a Truck Loading Unloading Belt Conveyor?

A Truck Loading Unloading Belt Conveyor is a device used in warehouses, ports, and stations to quickly load and unload cargo onto and off trucks. Compared to traditional manual handling methods, belt conveyors offer the following advantages:

Significantly Improved Loading and Unloading Efficiency: Belt conveyors can continuously transport goods at a constant speed, significantly reducing the time required to move individual items. For example, telescopic conveyors can reach deep into truck compartments, reducing the distance manual handling requires, enabling rapid point-to-point operations. This not only increases loading and unloading speeds but also reduces waiting time, improving truck turnover efficiency.

Reduced Labor Intensity and Labor Costs: Belt conveyors eliminate the need for workers to perform repetitive tasks such as long-distance carrying, bending, and lifting heavy objects, reducing the physical burden. This helps reduce the risk of workplace injuries and fatigue, leading to long-term labor cost savings. Some more automated equipment can even be operated by one person, further optimizing staffing.

Reduced Cargo Damage: Belt conveyors provide a smooth, continuous conveying surface, preventing damage to goods caused by drops, collisions, or improper handling during handling. Especially for fragile or irregularly shaped items, mechanized conveying can better protect their integrity and reduce the company's risk of compensation. Improved Work Safety: Compared to manual handling, belt conveyors separate goods from personnel, reducing the risk of crushing, falls, and other accidents during handling. Furthermore, hydraulic conveyors can adjust their height and angle to accommodate trucks of varying heights, eliminating the risks of manual handling on uneven surfaces.

Adaptable and Versatile: Truck Loading Unloading Belt Conveyors offer excellent flexibility. Mobile conveyors can be easily moved between different loading and unloading ports or work areas; telescopic and hydraulic types can accommodate trucks and containers of varying sizes, as well as platforms of varying heights, meeting diverse logistics needs. They can handle a wide range of cargo types, including boxed, bagged, parcels, and sacks, offering a wide range of applications.

Truck Loading Unloading Belt Conveyor Parameters

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

How does a Truck Loading Unloading Belt Conveyor work?

A truck loading unloading belt conveyor is a convenient material handling device, particularly effective at seamlessly connecting warehouses and trucks. The working principle of a belt conveyor can be broken down into several key components. The drive system is the conveyor's power source and typically consists of an electric motor and a speed reducer. The motor, through the speed reducer, provides a stable, appropriate speed, driving the drive roller. The conveyor belt is the component that carries and moves the goods. It is typically made of high-strength, wear-resistant rubber, polyvinyl chloride (PVC), or other composite materials. It is stretched taut between the drive roller and the bend roller, forming a closed loop. The roller system primarily consists of the drive roller and the bend roller. Driven by the motor, the drive roller rotates, creating motion through friction with the conveyor belt. The bend roller changes the direction of the conveyor belt. Numerous idlers are evenly distributed along the upper and lower ends of the conveyor belt. The upper idlers support the conveyor belt carrying the goods, preventing it from sagging; the lower idlers support the conveyor belt on the return journey. These idlers ensure smooth conveyor belt operation and reduce frictional resistance. When loading or unloading is required, workers place the goods at the starting end of the conveyor belt. The drive system activates, driving the conveyor belt to run smoothly, moving the goods along the conveyor belt. Telescopic conveyors extend their mechanism into the truck bed, delivering goods directly to their destination or removing them from the truck bed. Mobile conveyors can be moved to the appropriate location for loading and unloading. The entire process eliminates manual handling, allowing goods to be moved seamlessly from their starting point to their destination.

What are the applications of truck loading unloading belt conveyors?

Truck loading unloading belt conveyors have a wide range of applications, covering nearly all industries and locations requiring rapid cargo loading and unloading. Their core value lies in transforming traditional manual handling into mechanized and automated operations, significantly improving efficiency and safety.

Logistics and express delivery industries: Large logistics sorting centers and express delivery warehouses require massive amounts of parcels, letters, and small shipments to be loaded and unloaded daily. Telescopic belt conveyors can extend directly into the truck bed, enabling rapid and continuous loading and unloading of parcels, significantly reducing vehicle downtime and improving sorting and transportation efficiency. E-commerce warehouses and distribution centers: Belt conveyors play a critical role in unloading and loading bulk goods from suppliers into warehouses or loading packaged customer orders onto trucks for delivery. They smoothly and quickly handle cartons and packages of various sizes, ensuring timely delivery of orders.

Manufacturing and factories: In finished goods warehouses and distribution centers, belt conveyors are used to quickly load finished goods (such as home appliances, food, beverages, and building materials) off the production line onto trucks for shipment to distribution channels or retail outlets. The flexibility of mobile belt conveyors allows them to serve different production lines or loading and unloading ports, improving overall factory logistics efficiency.

Ports and terminals: Belt conveyors are commonly used in ports and terminals for loading and unloading bulk materials (such as grain, coal, ore, and cement). Hydraulic belt conveyors can flexibly adjust the conveyor belt's angle and height to accommodate the height differences between ships and trucks, ensuring smooth transport of bulk materials and avoiding extensive secondary handling.

Agriculture and food processing: In the agricultural sector, belt conveyors are used to load agricultural products such as grain, fruits, and vegetables from fields or warehouses onto trucks. In food processing plants, they are used to load finished products (such as bags of flour, rice, and beverage cartons) onto trucks for transportation to distribution networks. These applications demand equipment that is hygienic, wear-resistant, and highly efficient.

Truck Loading Unloading Belt Conveyors, as loading and unloading tools, play specific roles in a variety of operating environments. Designs such as telescopic, mobile, and hydraulic types enable them to accommodate vehicles of varying sizes, cargo shapes, and loading and unloading points at varying heights. Through mechanization, these devices are transforming the operational model of goods distribution. In warehouses, sorting centers, and manufacturing plants, these devices serve as a link in the logistics chain, transitioning goods from static storage to dynamic transportation.

Truck Loading and Unloading Belt Conveyor Customer Case Study

A logistics and warehousing company specializes in the transshipment of building materials and industrial parts, loading and unloading over 50 10-ton trucks daily. After introducing a customized Truck Loading and Unloading Belt Conveyor, the company reduced the loading and unloading time per truck to 35 minutes, and the cargo damage rate dropped to less than 0.5%. The system has been operating stably for 18 months, with a failure rate below 1%, ensuring cargo flow during peak season.

Truck Loading and Unloading Belt Conveyor Solution

The Truck Loading and Unloading Belt Conveyor allows flexible design of conveyor length, inclination, and height based on truck type (e.g., van, flatbed), cargo characteristics (e.g., granular, boxed, bagged), and loading/unloading space, ensuring precise alignment with the truck's cargo bed. The system is equipped with an adjustable-speed motor, adjusting conveyor speed based on cargo weight. Anti-slip belts and side ribs effectively prevent cargo from slipping. Some solutions also incorporate lifting and telescoping functions to accommodate trucks of varying tonnages and loading/unloading requirements.