What are the uses of Z Type Conveyor?

Friday August-15 2025 15:48:24

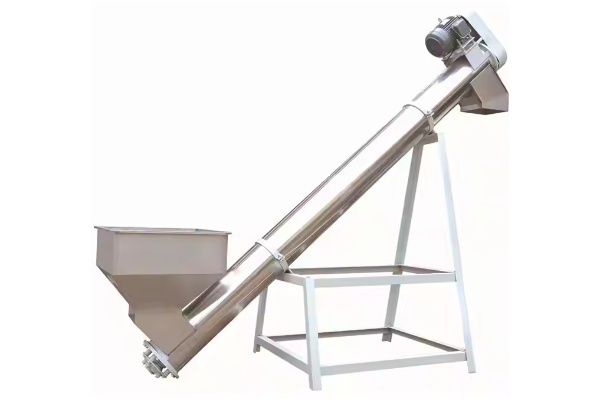

Z Type Conveyor enables both horizontal conveying and vertical lifting within a single device, solving material transfer challenges caused by height differences within production lines. It is suitable for conveying a variety of bulk materials, such as granules, powders, or small pieces. It is primarily used to smoothly lift materials from low to high locations, connecting production equipment at different heights and achieving continuous material conveying within confined spaces. Its structural design minimizes material impact during conveyance, making it suitable for handling fragile materials.

What equipment is the Z Type Conveyor compatible with?

Due to its unique structural design, the Z Type Conveyor enables both horizontal conveying and vertical lifting, playing a vital role in material transfer in many industrial scenarios. It is often used as a key link in production lines, in conjunction with other equipment to achieve continuous, automated material handling.

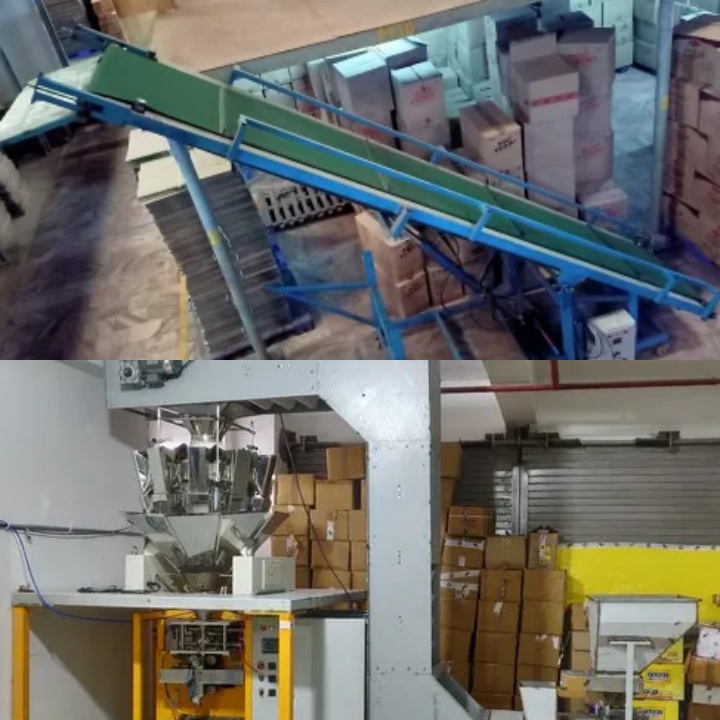

In conjunction with packaging machines: In the food and chemical industries, the Z Type Conveyor is often used to lift materials from a ground-level hopper to the elevated inlet of a packaging machine. For example, it can stably convey granular candies, snacks, or powdered condiments to the weighing hopper of a packaging machine or bag-making machine. This ensures a continuous packaging process and reduces the need for manual handling.

Integrating with a mixer: In production lines where multiple materials need to be mixed in a specific proportion, the Z Type Conveyor can lift different materials individually from the ground level to a high-level mixer. This integration simplifies the material feeding process while ensuring the correct order and proportion of different materials, improving mixing efficiency and product quality.

Integrating with a screener: In production lines where materials are graded or impurities are removed, the Z Type Conveyor can first lift the materials to a high-level screener. After passing through the screener, materials that meet the requirements are transported to the next process step, while those that do not meet the requirements are discharged. This integration enables automated material grading and improves production efficiency.

Integrating with a fine crusher: In production lines where materials need to be pulverized, the Z Type Conveyor is often used to lift and feed lumpy materials into the feed inlet of a high-level fine crusher (or pulverizer). This allows for smooth material handling and reduces the difficulty of material transfer caused by height differences between equipment.

In short, the Z-Type Conveyor, through its unique structure, can effectively connect equipment at different heights on the production line, enabling automated and continuous material handling, thereby optimizing the production process and improving overall production efficiency.

What are the uses of the Z Type Conveyor?

The Z Type Conveyor effectively overcomes height differences, smoothly lifting materials from lower to higher locations and connecting production equipment at different heights. Its compact "Z"-shaped layout enables vertical material lifting within limited spaces, improving space utilization. Furthermore, it provides a continuous and stable material flow and smoothly transports fragile or specialized materials, meeting diverse production needs.

Overcoming height differences: When different equipment on the production line is located at different heights, the Z Type Conveyor can serve as a connection point, smoothly transporting materials from lower to higher locations. For example, it can lift materials from a storage silo to a mixer, packaging machine, or weighing equipment located at a higher level. This integrated solution eliminates the need for multiple independent conveying devices, streamlining production processes.

Material Lifting in Limited Spaces: In factories or workshops with limited space, installing a traditional inclined belt conveyor can consume significant floor space. The Z Type Conveyor, with its compact "Z"-shaped layout, can accomplish vertical material lifting tasks within a smaller footprint, making more efficient use of space.

Continuous Conveying of Bulk Materials: The Z Type Conveyor is an ideal choice for production lines that require continuous and stable conveying of bulk materials from low to high locations. It can handle a variety of granular, powdered, or small-block materials, providing a continuous material flow and ensuring the continuity of downstream production or processing.

Conveying Fragile or Specialty Materials: The Z Type Conveyor typically uses a hopper or baffle to hold the material on the conveyor belt, ensuring a smoother conveyance and minimizing damage from drops or impacts. Therefore, it is also suitable for conveying fragile materials or those with special conveying requirements.

The specific application of the Z Type Conveyor varies depending on its location in the production line and the material it handles. For example, when used with a packaging machine, it stably delivers materials to the packaging machine's inlet, ensuring a continuous packaging process. When used with a mixer or screener, it facilitates material feeding and grading. The Z Type Conveyor's design can be adjusted to suit site space, and the location and size of its inlet and outlet can be adapted to the needs of upstream and downstream equipment. Therefore, it can become a flexible link in the production line, meeting diverse material transportation tasks.