Chain Conveyor Transporting Coal

The price of Chain Conveyor Transporting Coal ranges from $100 to $7,800 or even higher, depending on its type, length, conveying capacity, material, and customization requirements.

Chain plate width: 1200-2600mm

Chain plate material: carbon steel, stainless steel, plastic

Delivery capacity: 15-60 cubic / hour

Conveying distance: 70 meters

Conveying speed: 7-14 m/min

Motor power: 3-55kw

What is Chain Conveyor Transporting Coal?

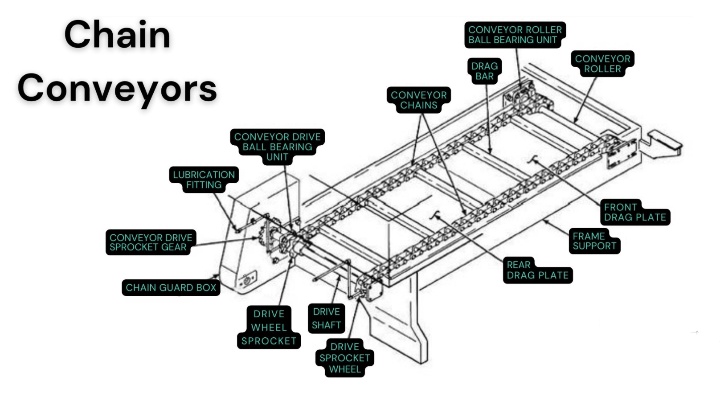

Chain Conveyor Transporting Coal are primarily responsible for moving coal between the various stages of production, processing, and utilization. Chain conveyors are primarily divided into two categories based on their structure and conveying direction: scraper conveyors and chain bucket elevators. Scraper conveyors are typically used for long-distance, continuous material transport, with single units capable of conveying distances of up to hundreds of meters and handling capacities ranging from tens to thousands of tons per hour. Bucket chain elevators are commonly used in applications requiring vertical space. Both types of equipment provide strong support for coal material flow in their respective operating scenarios.

What are the types of chain conveyor transporting coal?

In the coal transportation sector, chain conveyor transporting coal are widely used due to their robust structure and reliable operation. Scraper conveyors and chain bucket elevators are two very common types, each with unique structural features and application scopes.

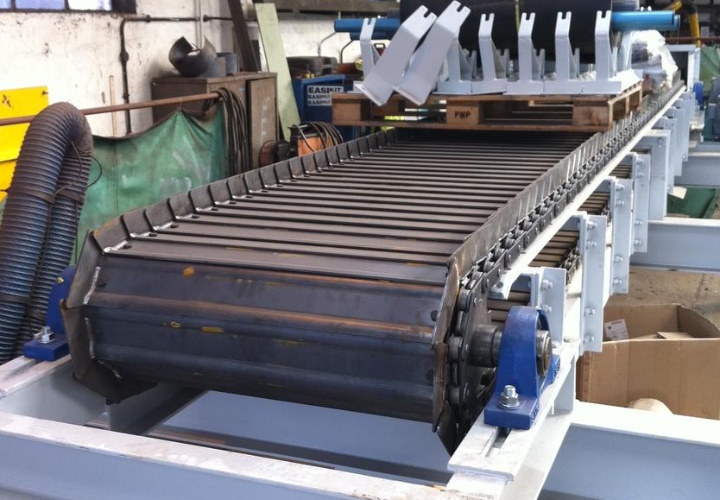

Scraper Conveyor

Structural Features

Scrapers and Chains: The core components are scrapers attached to the chain. During operation, these scrapers directly "scrape" the material, pushing it into a closed or semi-enclosed trough. Closed Trough: The conveyor trough is typically U-shaped or rectangular, where the material is continuously pushed forward by scrapers, effectively preventing spillage and dust emission. This design is particularly suitable for dust-prone materials such as coal.

Single or Double Chain: Depending on the conveying capacity and material characteristics, a single or double chain structure can be used. The double chain structure is typically used for heavy loads and high through puts, offering more stable operation.

Low-Speed, Heavy-Load: Scraper conveyors typically operate at lower speeds but offer high load capacity and can handle large, abrasive materials.

Applicable Materials: Primarily suitable for conveying bulk, granular, or small, lumpy materials horizontally or at a slight inclination (usually less than 20°). They are ideal for conveying materials such as coal, ore, cement, grain, and slag. Their closed design excels in environments requiring high containment and safety, such as underground coal mines and thermal power plants.

Chain Bucket Elevator

Structural Features

Hopper and Chain: The core component is a series of hoppers attached to a chain (or belt). These hoppers are loaded with material at the bottom and then lifted vertically to a specified height through the movement of a chain.

Enclosed Enclosure: The entire unit is typically enclosed within a vertical, enclosed enclosure, which helps prevent material spillage during the lifting process and reduces contamination.

Loading and Unloading: Material enters the hopper through the inlet at the bottom. Once at the top, it is discharged from the hopper into the outlet by centrifugal force or gravity.

Small Footprint: Due to its vertical conveying operation, chain bucket elevators occupy a very small footprint, making them ideal for locations with limited space.

Applicable Materials: Primarily suitable for vertical or near-vertical material lifting. Suitable for dry, loose, non-sticky granular and lumpy materials such as coal, ore, grain, fertilizer, and feed. It is not suitable for conveying highly viscous or moisture-rich materials, as these tend to adhere to the hopper walls, affecting lifting efficiency.

What are the advantages of using Chain Conveyor Transporting Coal?

Chain Conveyor Transporting Coal play a vital role in coal transportation, offering several unique advantages over other conveying equipment. The following are their key advantages:

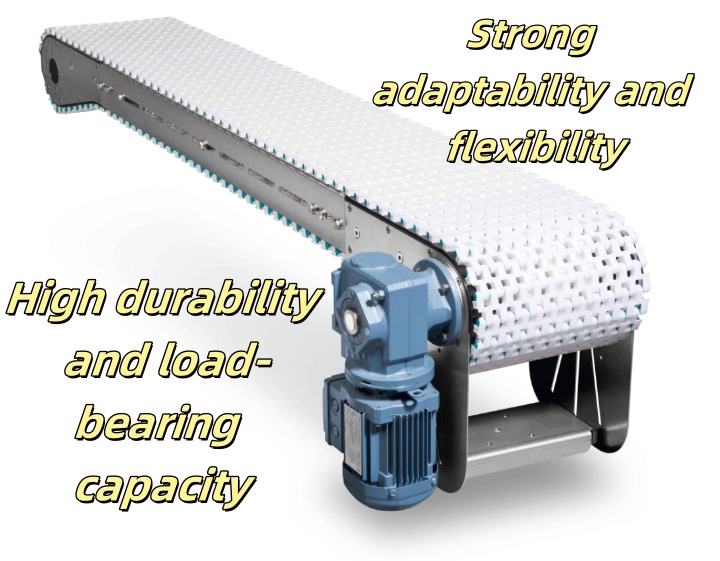

High durability and load-bearing capacity: Chain conveyors are typically constructed of high-strength steel, resulting in a robust structure that can easily handle heavy, bulky, and abrasive materials like coal. They are resistant to wear and have a long service life, making them particularly suitable for harsh industrial environments such as underground coal mines or open-pit coal yards.

Excellent sealing: Many chain conveyors, particularly scraper conveyors, utilize a fully enclosed trough design. This effectively prevents coal from spilling during transportation, significantly reducing dust emission, thereby lowering the risk of dust explosions, improving the working environment, and complying with stringent environmental regulations.

Strong adaptability and flexibility: Chain conveyors can be designed in a variety of layouts, enabling horizontal, vertical, and inclined conveying. They can be flexibly adjusted to meet site space and process requirements, particularly in applications requiring traversal of complex terrain or vertical lifting, where chain conveyors demonstrate unique advantages. Low Maintenance and High Reliability: Chain conveyors typically require low maintenance due to their robust construction and relatively simple drive system. Even when repairs are necessary, their modular design makes component replacement relatively simple, minimizing downtime and ensuring continuous production.

Space Utilization: Bucket chain elevators, as a type of chain conveyor, maximize vertical space utilization by lifting materials vertically, significantly reducing floor space. This is particularly important in factories or facilities with limited space.

Chain Conveyor Transporting Coal Parameters

| Model | Product name |

Chain pitch (mm) |

Ultimate strength of single chain (KN) |

Allowable chain tension (KN) |

Table width (mm) |

Load bearing (KGf/m) |

Speed (m/min) |

Operating temperature (℃) |

| BP40 | Light-duty flat chain conveyor | 8.1 | 31.1 | 8 | 200-300 | 50 | 1-12 | 0-150 |

| BP50 | 50.8 | 55.6 | 15 | 300 -400 | 100 | |||

| BP100 | Curved plate conveyor Single-lane plate conveyor Double-lane chain conveyor | 100 | 56 | 5 | 400-500 | 120 | ||

| BP150 | 150 | 136 | 30 | 600-800 | 200 | |||

| BP200 | 200 | 230 | 40 | 800-1200 | 500 | |||

| BP250 | 250 | 1000-1200 | 1200 | |||||

| BP300 | 300 | 1000-1500 | 1500 | |||||

| BP400 | 400 | 1200-1800 | 2000 | |||||

| DPB | Large flatchain conveyor (heavy duty) | 1500-3000 | 2000 | 1-20 |

How does a Chain Conveyor Transporting Coal work?

Chain Conveyor Transporting Coal by using the continuous motion of a chain to drive the conveying elements, moving coal along a specific path. While the operating methods vary slightly depending on the type, the core principle is always "chain drive."

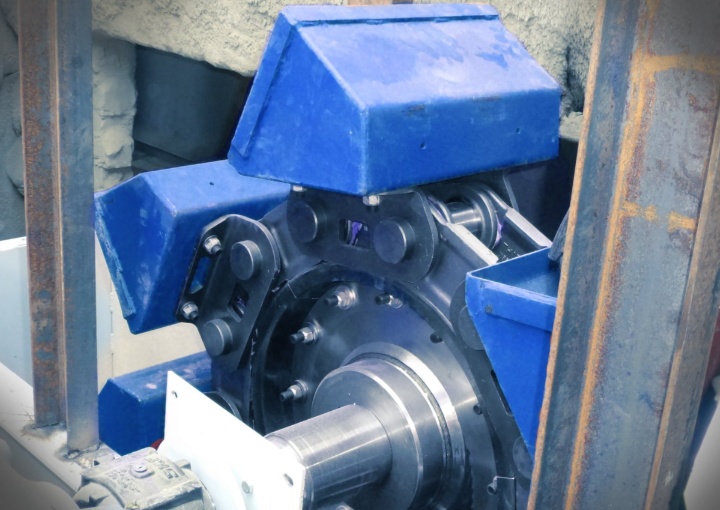

Scraper Conveyor

Drive and Circulation: Each end of the conveyor has a sprocket (also called a chain drive pulley). The drive end is powered by a motor and a reducer, which rotate the sprockets. The gears on the sprocket engage with the links on the chain, setting the closed chain system in motion.

Scraper Pushing: One or a group of scrapers are fixed at regular intervals on the chain. As the chain moves, these scrapers are positioned within a closed U-shaped or rectangular trough. The scrapers face the coal and, through direct contact with it, continuously propel it forward.

Material Conveying: After the coal enters the trough from the feed inlet, it is carried by the scrapers along the bottom of the trough, transporting it to the discharge outlet. The entire process is slow, smooth, and continuous. The closed trough effectively prevents material spillage and dust.

Chain Bucket Elevator

Drive and Circulation: The elevator has a drive wheel and a redirecting wheel at each top and bottom. The motor drives the sprocket at the top, driving the chain, which is attached to a series of hoppers, in a vertical, circular motion.

Material Loading and Elevating: When the chain reaches the bottom, the hopper "scoops" coal from the feed inlet. Due to the orientation of the hopper opening, the coal flows naturally. As the chain moves upward, the coal in the hopper is lifted vertically.

Material Unloading: When the hopper reaches the top drive wheel, it flips due to centrifugal force and gravity, unloading the coal inside into the discharge port, completing the vertical conveying process.

What are the uses of chain conveyor transporting coal?

Due to their sturdiness, durability, and flexibility, Chain Conveyor Transporting Coal are widely used in various aspects of the coal industry. Their main uses can be summarized as follows:

Underground Coal Mine Transportation

Working Face Transportation: Scraper conveyors can work directly with shearers to continuously transport mined coal from the working face to other conveying equipment in the roadway (such as belt conveyors).

Tunnel Transportation: They serve as the primary transportation tool in the roadway, gathering coal from different areas and transporting it to the surface or to the next transportation link, ensuring smooth coal flow. Thermal Power Plant

Coal Intake and Storage: Coal is unloaded from trains, ships, or trucks and transported to coal crushers or coal yards for storage.

Boiler Coal Supply: Chain conveyors are responsible for removing coal from coal yards or coal storage bunkers and accurately and steadily transporting it to the boiler's pulverizers, ensuring sufficient fuel for boiler combustion and maintaining stable generator operation.

Vertical Lift: Chain bucket elevators are particularly suitable for lifting coal from the ground to elevated coal bunkers, effectively utilizing limited space.

Coal Processing and Washing Plant

Material Handling: In coal washing plants, chain conveyors are used to transport raw coal between equipment such as screens, crushers, and jigs for grading, impurity removal, and purification.

Clean Coal Transportation: Clean coal after washing is also transported by chain conveyors to stockpiles or loading points for shipment.

Chain Conveyor Transporting Coal is a practical industrial equipment used in various locations, including underground coal mines, thermal power plants, and coal processing plants. They are responsible for transporting coal from one location to another, ensuring the continuity of production and processing. Whether in complex underground tunnels or in specific workstations within a plant, their design and operation are designed to meet specific process requirements and site conditions, making them an indispensable part of the coal handling system.