pvc belt conveyor

PVC belt conveyors can provide material handling capacity from 5 to several hundred cubic meters per hour, and prices range from $100 - $3,000.

Conveying capacity: 5m³/h-200 m³/h

Conveying distance: 2m-100m

Motor power: 0.75 kW to 15 kW

Appearance: open, skirt, closed

Tilt angle: generally between 0° and 25°

Application: Mainly used in food processing industry,electrical industry etc.

What is PVC belt conveyor?

pvc belt conveyor is a kind of equipment mainly used for light material transportation in various industries. Its main function is to realize the smooth transfer of materials in production or logistics through a continuously running polyvinyl chloride (PVC) conveyor belt.This type of conveyor can be divided into many types according to its structure and purpose, including general-purpose types for horizontal or inclined transportation, and climbing types designed to cope with height differences. In addition, there are food-grade models customized for specific industries such as food processing.It can handle all kinds of bulk, bagged, boxed or pieced materials, and its conveying capacity and speed can be adjusted according to actual needs.

There are many types of PVC belt conveyor, designed to meet different material conveying needs. First, it is necessary to clarify the conveying path of the material. If the material needs to move on the same horizontal plane, then the horizontal PVC conveyor is the direct choice. They are relatively simple in structure and suitable for most linear transmission tasks on production lines. When the material needs to move between different heights, the inclined PVC conveyor can play a role. This type of conveyor can convey materials up or down at a certain angle, making effective use of vertical space. For scenes with large height differences or even requiring materials to be lifted to a large height, climbing PVC conveyors are designed for this purpose. They are usually equipped with special anti-slip belts or baffles to ensure that the material can be transported stably at a large inclination angle. In addition to the basic structural type, the characteristics of the material itself also have a direct impact on the selection. In addition, PVC conveyor manufacturers also provide customized services. The width, length, belt type, frame material and control system of the conveyor can be customized according to the actual size of the production site, the specific properties of the material (such as whether it is fragile or corrosive), the conveying volume, speed requirements and the degree of automation.

What are the types of PVC belt conveyor?

PVC belt conveyor is a kind of light material conveying equipment with strong versatility and wide adaptability. Its type classification is mainly based on its structural characteristics, conveying function and the specific properties of the conveyor belt used.

Features: used to convey materials in the horizontal direction. Simple structure and smooth operation. Mainly used for connection, packaging, sorting, assembly, etc. between production lines.

Horizontal PVC Belt Conveyor

Horizontal conveyors are a common type. They are widely used in various production lines, packaging lines and sorting systems, and are suitable for conveying a variety of materials such as granules, powders, blocks, bags, etc. Horizontal conveyors perform well in scenarios where materials need to be conveyed over long distances and smoothly.

Inclined PVC Belt Conveyor

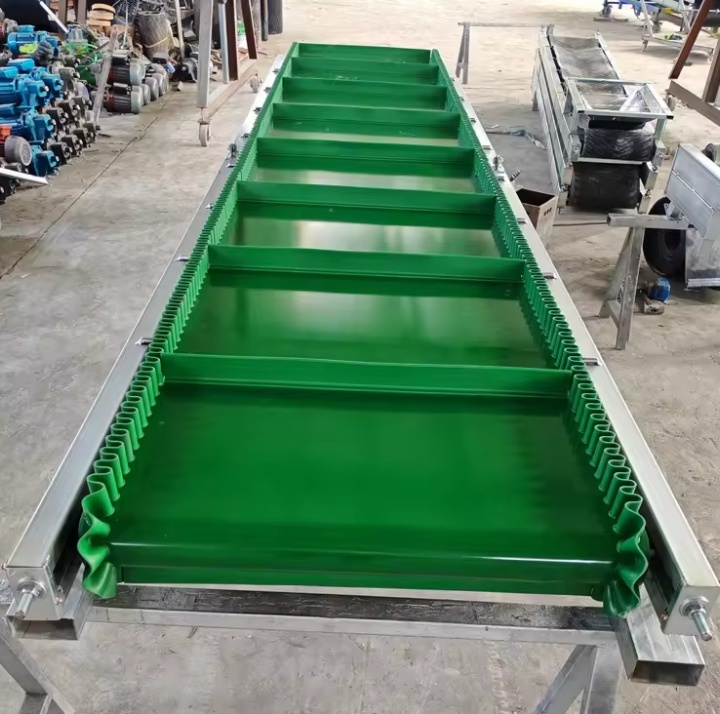

The conveyor belt of the inclined conveyor runs upward or downward at a certain angle, and is mainly used to convey materials between different heights. In order to prevent materials from slipping during inclined conveying, inclined conveyors usually use PVC conveyor belts with anti-slip patterns (such as grass patterns, fishbone patterns, checkered patterns, etc.), or add accessories such as baffles and skirts to the conveyor belts.

Z-type conveyors are a complex type that combines horizontal and inclined conveying, and its conveying path is shaped like the letter "Z". Z-type conveyors are often used in situations where materials need to be lifted from lower ground to higher production lines or packaging equipment, or unloaded from high to low. Similar to inclined conveyors, Z-conveyors are often equipped with anti-slip conveyor belts or baffles to ensure the stability of materials during vertical lifting.

What are the advantages of PVC belt conveyor?

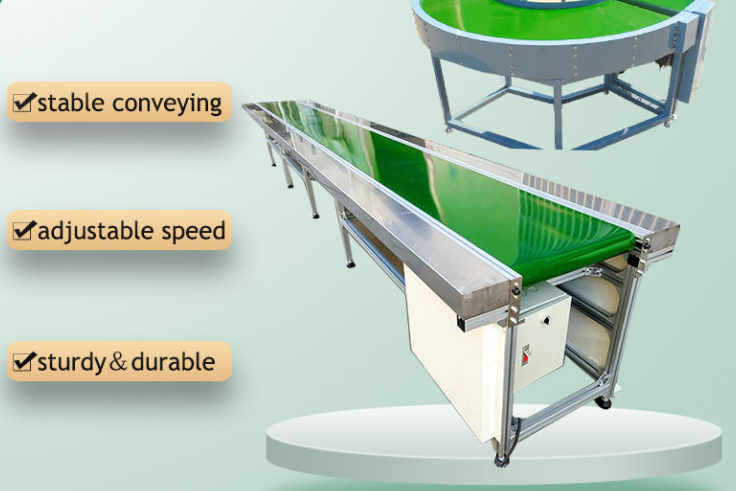

As a versatile material handling device, the PVC belt conveyor's advantage lies in its ability to adapt to a variety of material forms and production environments, and its design features ensure stability and flexibility during the conveying process. Its advantages include compatibility with material forms, flexible conveying directions, adjustable speeds, smooth operation, and lightweight design.

Material diversity: It can convey materials in various forms, including bulk, bagged, pieced and irregularly shaped items.

Flexible conveying direction: It can realize horizontal and inclined conveying. By choosing a conveyor belt with patterns or adding baffles and skirts, it is also easy to achieve large angle climbing conveying.

Adjustable speed: Most equipment can be equipped with a frequency converter to achieve stepless adjustment of the conveying speed to adapt to different production rhythms and process requirements.

Smooth operation and little damage to materials: The belt is used as a medium for carrying and driving. There is almost no relative movement between the material and the belt during the conveying process. Therefore, the conveying process is very smooth, the noise is low, and the damage to the conveyed material is small. It is especially suitable for fragile and wear-resistant items.

Lightweight and flexible to install: The PVC conveyor belt itself is relatively light, which reduces the weight of the entire conveyor and facilitates the handling, installation and rearrangement of the equipment. Different lengths and widths can be customized according to the actual needs of the production line, and auxiliary facilities such as guardrails and workbenches can be added to achieve personalized configuration.

What types of conveyor belts are available for PVC belt conveyors?

PVC belt conveyors have a variety of conveyor belt types, primarily differentiated by surface texture, additional features, and material thickness to accommodate different material conveying needs. The following is a detailed introduction to the different conveyor belt types:

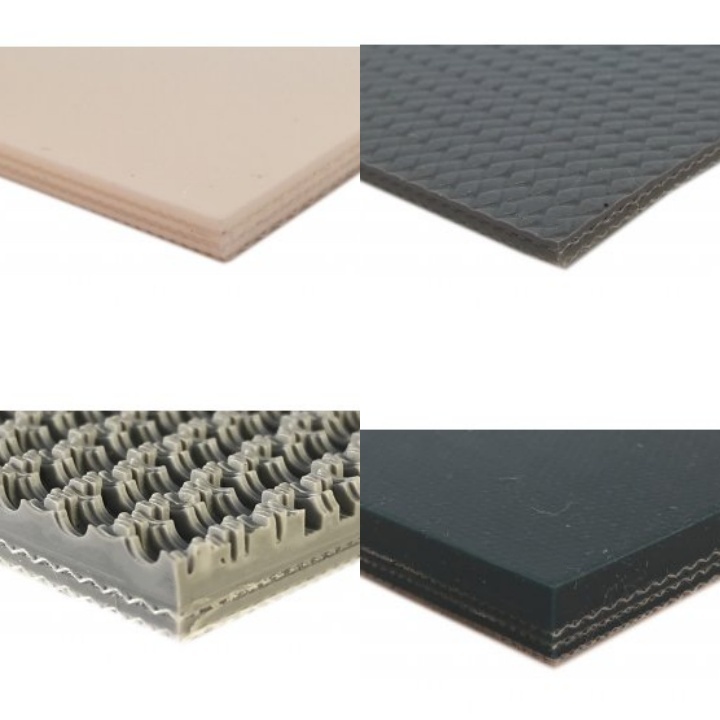

Classification by Surface Texture

Flat Belt: This is a common type with a smooth, flat surface. It is primarily used for horizontal or shallow-angle conveying, suitable for conveying boxes, bulk items, and various formed parts.

Patterned Belt: To increase friction and facilitate conveying at steep angles, the belt surface is embossed with various patterns, such as herringbone, diamond, and blade. This effectively prevents materials from sliding during conveying at inclines.

Classification by Additional Features

Skirted Baffle Belt: Skirted belts are installed on both sides of the belt, along with horizontal baffles, to prevent material from spilling during conveying. They are particularly suitable for conveying at steep angles or vertically.

Guide Strip Belt: Guide strips are installed at the bottom of the belt to prevent the belt from deviating during operation. They are typically used for narrow conveyors.

Classification by Material and Thickness

Although generally referred to as PVC belts, their thickness and strength vary depending on the internal fabric layers. Common options include one layer of fabric and one layer of adhesive, two layers of fabric and two layers of adhesive, or even more layers to meet varying load and strength requirements. PVC belts also come in a variety of colors, such as green, white, and blue. White and blue are often used in the food industry to meet hygiene standards.

Basic parameters of PVC belt conveyor

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

What are the applications of PVC belt conveyor?

PVC belt conveyor plays a role in a variety of material handling scenarios, mainly used to achieve continuous movement of materials on a given path. This type of equipment is widely used in various operating environments where materials need to be transferred from one point to another due to its stable operating characteristics.

Fixed-point transfer of materials: PVC belt conveyor can stably transport bulk, bagged, boxed or formed materials from one processing area or operating table to the next area to ensure the continuity of material flow.

Assisted manual operation: At work points where sorting, inspection, packaging or simple assembly are required, this type of conveyor is often used as a working platform for operators, and while the materials move on the conveyor belt, it is convenient for operators to intervene.

Adaptation of spatial layout: PVC belt conveyor can be arranged in multiple conveying directions such as horizontal and inclined according to site restrictions and process requirements, so as to adapt to material flow lines in different spatial environments.

Light material management: They are suitable for handling various relatively light and moderately sized items, avoiding repetitive labor of manual handling and helping to maintain the rhythm of material handling.

Aids in clean environment: The use of a smooth belt conveyor reduces the dust or scattering that may be generated during the conveying process, which helps to keep the work area clean.

PVC Belt Conveyor Examples

PVC belt conveyors are widely used in various industries due to their flexibility, adaptability, and cleanability. They are particularly well-suited for production environments with specific material handling requirements. For example, in electronic product assembly, testing, and packaging lines, PVC belt conveyors are widely used due to their smooth operation and customizability. They easily enable precise movement of products between workstations and can adjust conveyor speeds to match production rhythms, making them key equipment in automated production lines. In the food industry, white or blue food-grade PVC conveyor belts are highly favored for their non-toxic, oil-resistant, and easy-to-clean properties. PVC belt conveyors are commonly used for conveying, sorting, and packaging products such as baked goods, candy, meat, and vegetables, ensuring food hygiene and safety while minimizing contamination. In logistics centers and express delivery companies, PVC belt conveyors are a crucial component of sorting systems. They can quickly and accurately transport packages of varying sizes and shapes to designated areas, significantly improving sorting efficiency and reducing labor intensity. In addition to these key applications, PVC belt conveyors are also widely used in a variety of industries, including textiles, printing, tobacco, and woodworking, for handling and transporting a variety of lightweight materials. For example, they convey fabric or garments on clothing production lines, and paper or printed materials in the printing industry. In short, the applications of PVC belt conveyors are extremely diverse, and their design and functionality can be adjusted and customized to meet specific industry and production needs.

PVC belt conveyor manufacturers

Manufacturers usually show diversity in the product line of PVC belt conveyors. We not only provide standard horizontal, inclined and Z-type conveyors, but also produce customized products according to the specific needs of different industries. For example, in terms of horizontal conveyors, manufacturers can provide wider belts and heavier load-bearing capacity to meet the conveying needs of large materials. For inclined conveyors, the difference is reflected in the type of belt pattern and the maximum inclination angle. The design diversity of Z-type conveyors is reflected in the angle of its "Z" shape and the length ratio of each section. In addition to standardized products, manufacturers also have the ability to customize production. We can adjust the size, material, speed, load capacity, and automatic control system of the equipment according to the specific needs of customers. Therefore, manufacturers can provide customers with conveying solutions that are more in line with actual production scenarios, ensuring that the equipment can be better integrated into the existing production process.

Daily maintenance of the PVC belt conveyor, such as cleaning the conveyor belt, checking the wear condition, and the stability of the drive system, are the basis for ensuring its continued operation. The characteristics of PVC material make it adaptable in specific temperature and chemical environments and easy to clean. These conveyors can be installed in a variety of configurations according to the specific space and process flow of the factory to adapt to different material flows and operating requirements.