Skirt belt conveyor

The price of Skirt belt conveyor varies greatly depending on its specific model, conveying length, lifting height, bandwidth. Its price ranges from US$200 to US$5,000.

Size: 1m/2m/3m/customized

Length: 50-6000mm/customized

Power: 2.2 kW

Speed: 0.5-1.5 m/min

Power supply: 110V/220V/380V

Material: rubber/stainless steel/carbon steel/pvc

What is Skirt belt conveyor?

The Skirt belt conveyor forms a closed "hopper" structure by adding flexible corrugated sidewalls (commonly known as skirts) on both sides of the traditional conveyor belt and setting transverse partitions on the bearing surface. This design enables it to complete material transportation in horizontal, inclined and even vertical directions. Whether it is used for large-angle lifting, Z-type transfer, or horizontal transportation under specific environments, Skirt belt conveyor provides a stable material handling solution to ensure the continuous movement of materials on complex paths. It adapts to different material characteristics and conveying paths and can handle various types of bulk materials, such as granular, powdered or small block materials.

Skirt belt conveyor can be mainly divided into several types according to its unique conveying path and angle to meet different material handling needs. The most common one is the large-angle Skirt belt conveyor, which can achieve vertical lifting of materials from 0 degrees to 90 degrees. The second is the horizontal Skirt belt conveyor. The conveyor belt with skirts and partitions can effectively prevent material spillage in the horizontal section, ensuring the stability of transportation and the integrity of the material. Finally, there is the Z-type Skirt belt conveyor, which is suitable for complex working conditions where materials need to be moved horizontally, then lifted vertically, and finally output horizontally again, providing a flexible and continuous conveying solution.

What are the types of Skirt belt conveyors?

Skirt belt conveyor is a special belt conveyor that adds flexible corrugated sidewalls (skirts) on both sides of the ordinary conveyor belt and adds transverse partitions on the surface of the conveyor belt. This makes it difficult for materials to fall during transportation, especially for large-angle transportation. According to its conveying angle and layout, Skirt belt conveyor can be mainly divided into the following types:

Skirt belt conveyor with large inclination angle

Features: This is a typical application of Skirt belt conveyor, which can achieve large inclination angles of 0° to 90° or even vertical transportation. Due to the fixation of skirts and partitions, materials will not slide in the inclined or vertical direction.

Advantages: It saves space significantly, especially suitable for places with limited space. It can replace traditional equipment such as bucket elevators, reduce transfer links, and reduce material damage.

Horizontal Skirt belt conveyor

Features: Although Skirt belt conveyor is known for large-angle transportation, it can also be used for horizontal transportation. In this case, the main function of the skirt and partition is to prevent the material from overflowing due to vibration or centrifugal force during transportation.

Advantages: It can increase the conveyor belt's handling capacity in the horizontal conveying system, and is particularly suitable for materials that require a higher conveying capacity.

Application: It is suitable for horizontal conveying scenarios where materials need to be prevented from scattering, such as the conveying of certain fine materials or materials that are easily affected by wind.

Z-type Skirt belt conveyor

Features: The Z-type Skirt belt conveyor is a composite form that combines horizontal and inclined conveying. Its conveying path is in the shape of a "Z", that is, it first conveys horizontally for a section, then lifts at a large angle, and finally conveys horizontally for a section.

Advantages: This form combines the space-saving advantage of large-angle conveying with the convenience of horizontal conveying, and can achieve continuous lifting and turning of materials.

Application: It is often used in situations where materials need to be lifted from a lower height to a higher height and conveyed between different horizontal planes, such as vertical transfer and horizontal conveying of materials in factory workshops.

What are the advantages of Skirt belt conveyor?

Skirt belt conveyor has many advantages over traditional conveying equipment. First, it can achieve large-angle or even vertical conveying, which greatly reduces the floor space required for the equipment, which is a significant feature for industrial sites with limited space. Secondly, through its unique skirt and partition structure, it can effectively prevent material spillage and keep the material stable even during inclined or vertical conveying, which helps to reduce material loss and keep the working environment clean. In addition, the skirt belt conveyor can achieve continuous and uninterrupted material conveying, which helps to improve the efficiency of the production line and the material handling capacity. It can also integrate horizontal, inclined and vertical conveying on one belt, reducing the material transfer link, thereby simplifying the process and reducing maintenance requirements.In addition to saving space and reducing transfer, the skirt belt conveyor also performs well in adaptability. It can handle various types of bulk materials, whether powder, granular or small pieces, and can be stably transported with the cooperation of skirts and partitions. This structure also helps to reduce the impact of the external environment on the material to a certain extent, for example, in dusty or windy conditions, it can better protect the material from being blown away. At the same time, its continuous operation characteristics ensure the smoothness and stability of the material transportation process, which is especially important for industrial occasions where the production line needs to run uninterruptedly.

Parameters of Skirt belt conveyor

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

What is the principle of Skirt belt conveyor?

The working principle of Skirt belt conveyor is to use the synergy of corrugated sidewall conveyor belt, transverse partition and tensioning device to realize large-angle or even vertical conveying of bulk materials. The core lies in the special conveyor belt structure: corrugated sidewalls (commonly known as "skirts") with certain flexibility and height are bonded on both sides of the ordinary flat belt, and transverse partitions with certain strength and height are periodically bonded on the bearing surface of the conveyor belt. When the conveyor is running, the drive device drives the conveyor belt to circulate under the action of the roller and the drive roller. The material is evenly loaded onto the bearing surface of the conveyor belt with partitions. Due to the existence of the skirt, independent "hopper" spaces are formed, which effectively prevents the material from being scattered along both sides of the conveyor belt during the conveying process. At the same time, the transverse partition plays the role of carrying and supporting the material. Even when the material is at a large angle or even lifted vertically, it can rely on the blocking effect of the partition to prevent the material from sliding or rolling down due to gravity. In addition, the tensioning device ensures that the conveyor belt maintains proper tension during operation, prevents deviation and slippage, and ensures the stability and continuity of transportation. Through this unique combination, the Skirt belt conveyor can break through the limitation of traditional flat belt conveyors that can only transport at a small angle, and realize the transportation of materials at any angle within the range of 0° to 90°, saving space, improving transportation efficiency, and reducing intermediate transfer links.

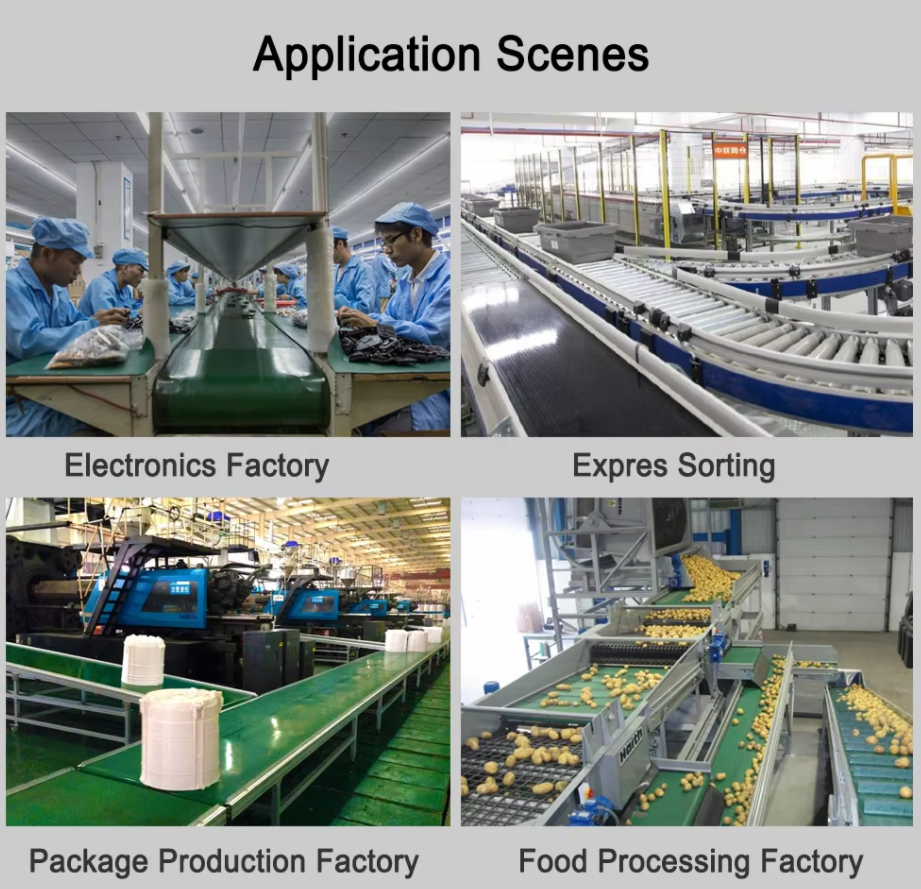

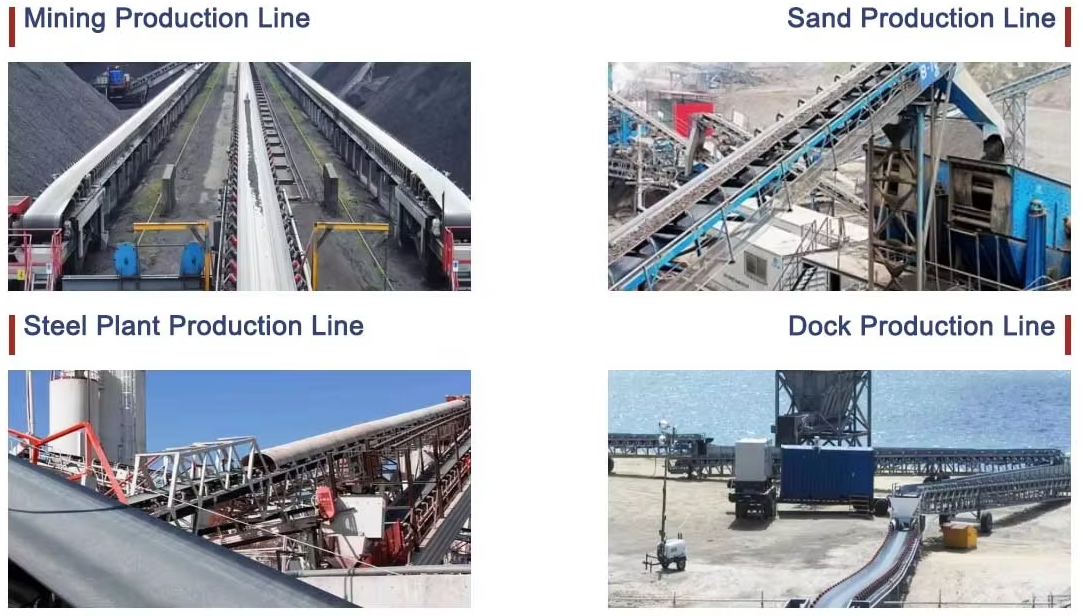

What are the applications of Skirt belt conveyor?

Skirt belt conveyor is a multifunctional conveying equipment, which is mainly used in scenarios where bulk materials need to be conveyed at a large angle or vertically. Its core advantage is that it can achieve continuous lifting of materials, breaking through the limitations of traditional flat belt conveyors in terms of inclination angles.

Vertical or large-angle lifting: This is a significant application of Skirt belt conveyor. When materials need to be lifted from a lower height to a higher height and the site space is limited, it can achieve vertical transportation up to 90 degrees, saving floor space and reducing infrastructure costs.

Material space transfer: In the production process, if materials need to be transported from one workshop or one equipment to another workshop or equipment at a different height, Skirt belt conveyor can provide a direct and continuous conveying path, avoiding multiple transfers and possible material spillage or contamination.

Closed conveying: Due to the design of the skirt and the diaphragm, the material is effectively surrounded on the conveyor belt, which is very beneficial for occasions where dust needs to be reduced, material contamination needs to be avoided, or material moisture needs to be prevented, which helps to improve the working environment and protect the quality of the material.

Multi-point feeding and discharging: In some complex process flows, materials may need to go through multiple processing links during the transportation process. Skirt belt conveyor can be designed to feed or discharge materials at different points, increasing the flexibility and automation of the system.

Skirt belt conveyor case

Skirt belt conveyor, with its unique structural advantages, has demonstrated excellent performance in many areas where traditional conveying equipment is difficult to handle. Its main application scenarios are concentrated in industrial production that requires large-angle or vertical conveying of bulk materials. It can be used for lifting and conveying materials such as coal, ore, and gangue in coal mines or open-pit mines. Thermal power plants require a large amount of coal as fuel. Skirt belt conveyors can be used for coal yards, lifting before conveying to boiler rooms, and conveying and processing slag and ash. In building materials production, Skirt belt conveyors can be used for vertical lifting or large-angle conveying of bulk materials such as cement, limestone, sandstone, and crushed stone, such as material transfer between crushers, mills, silos and other equipment. Skirt belt conveyors are also often used to transport materials such as fertilizers, salt, sulfur, and various chemical powders and granules. Especially when materials need to be transported from the ground to high places such as reactors and storage tanks, its large-angle conveying capacity is particularly important. In steel mills, non-ferrous metal smelters and other places, high-temperature and highly abrasive materials such as iron ore, coke, sintered ore, and slag need to be transported reliably. Skirt belt conveyors can also play a role in specific material handling links. In grain storage and port terminals, bulk grains, feeds, grains, etc. need to be loaded and unloaded and transferred quickly. Skirt belt conveyors can be used for ship loading and unloading, warehouse stacking or silo lifting. In general, Skirt belt conveyors provide a reliable solution in industrial production that needs to solve height difference transportation, limited space, environmental control, and continuous processing of bulk materials.

Skirt belt conveyor, with its unique design, provides a feasible solution for handling bulk materials that are limited in space or require significant height difference transportation. Its main feature is the use of corrugated sidewalls and cross partitions, which prevents materials from being scattered during transportation, especially suitable for inclined or vertical lifting. In addition, its strong adaptability enables it to cope with various complex site layouts, while the continuous and stable transportation method helps to maintain production stability. This integrated transportation path reduces the number of material transfers between different transportation links, thus helping to keep the production process smooth and continuous.