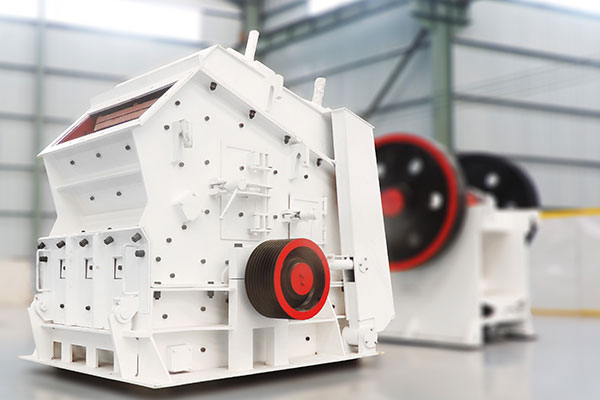

jaw crusher

jaw crusher uses cyclic squeezing motion between its movable and fixed jaws to crush a variety of medium- to high-hardness materials, providing primary crushing for industries such as mining and building materials. Processing capacity: 5-1000 t/h, depending on the model Feed opening dimensions: 100×60mm to 1500×2100mm Discharge opening adjustment range: 5-300mm to accommodate different needs Motor power: 4-200kW to ensure power Machine weight: 1-100t, which may affect installation and transportation Applicable materials: Ores and rocks with a compressive strength of ≤320 MPa

What is a jaw crusher?

jaw crusher is a common and widely used crushing device. It can handle materials of varying hardness, such as high-hardness granite, medium-hardness river pebbles, and relatively soft limestone. In practice, the feed size of a jaw crusher typically ranges from 125mm to 1200mm, depending on the model and design parameters. The discharge particle size is generally adjustable between 10mm and 350mm, allowing users to tailor this to their production needs. The production capacity range is very broad, ranging from small pilot units with a capacity of 1 t/h to large-scale production equipment with capacity exceeding 1,000 t/h. Therefore, it is suitable for a wide range of applications, including sand and gravel aggregate production, cement production lines, mining, and construction waste recycling.

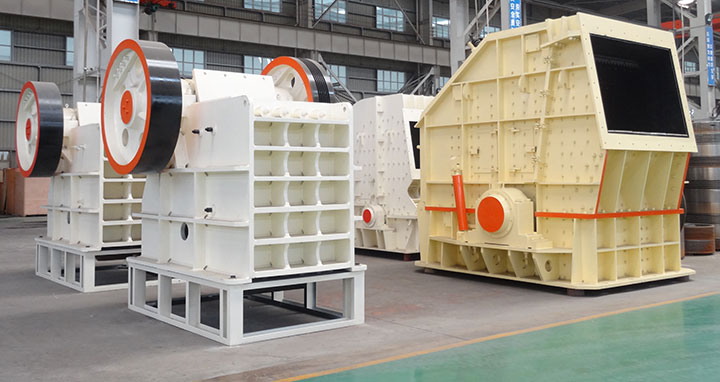

What types of jaw crushers are there?

Jaw crushers can be divided into the following categories based on their structure and application:

PE Series (Traditional): This series features a classic structural design and a long history of use, offering stable operation, simple structure, easy maintenance, and high durability. It is suitable for small and medium-sized production capacity requirements and is commonly used in small and medium-sized sand and gravel plants or mines.

PEX Series (Fine Jaw Crusher): This series is primarily used for secondary or fine crushing. Compared to the PE Series, it has a smaller discharge opening, achieving a finer finished particle size, making it suitable for sand making or mineral processing operations with high particle size requirements.

CJ/HD Series (European Version/New Jaw Crusher): Based on the traditional jaw crusher design, this model features an increased eccentricity, a deeper crushing chamber, greater processing capacity, and lower energy consumption. Its advanced design makes it suitable for large-scale sand and gravel aggregate production lines, particularly in projects with high production capacity and energy efficiency requirements.

Mobile Jaw Crusher (Crawler/Tire): Combining the advantages of a jaw crusher with a mobile crushing station, it offers high flexibility and can be moved around the site. It is ideal for applications such as construction waste recycling, urban demolition, and decentralized mining.

Jaw Crusher Technical Specifications

| Model | Feeding size(mm) | Max feeding size(mm) | Discharging Range size(mm) | Capacity (t/h) | Motor power(kw) | Weight (t) |

| PE-250*400 | 250*400 | 210 | 20-60 | 5-20 | 15 | 2.8 |

| PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.5 |

| PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 10.6 |

| PE-600*900 | 600*900 | 500 | 65-180 | 80-180 | 55-75 | 15.5 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 90-110 | 28 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 90-110 | 30 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 90-110 | 30.5 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 90-110 | 31 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 110-132 | 49 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 110-132 | 51 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160 | 100.9 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 22 | 4.9 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37 | 7.7 |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 75 | 11 |

Jaw Crusher Compatible Equipment

Jaw Crusher is often used in conjunction with other equipment to complete the production process:

Feeder: This unit is responsible for evenly and continuously feeding large pieces of stone into the crushing chamber, preventing blockages or impacts caused by sudden overfeed.

Conveyor and Screening Equipment: The conveyor transports the crushed material to the screening equipment, where the finished material is separated from the bulk material, ensuring a uniform particle size that meets market demand. Iron removers and dust removal systems: Ores and construction waste often contain metallic impurities. Direct entry into the crushing chamber can damage the equipment, so iron removers are necessary for separation. Furthermore, dust is generated during the crushing process. Installing a dust removal system not only helps meet environmental standards but also improves the working environment for workers.

By strategically integrating these auxiliary equipment, the jaw crusher can operate more efficiently and stably, meeting the overall needs of the production line.

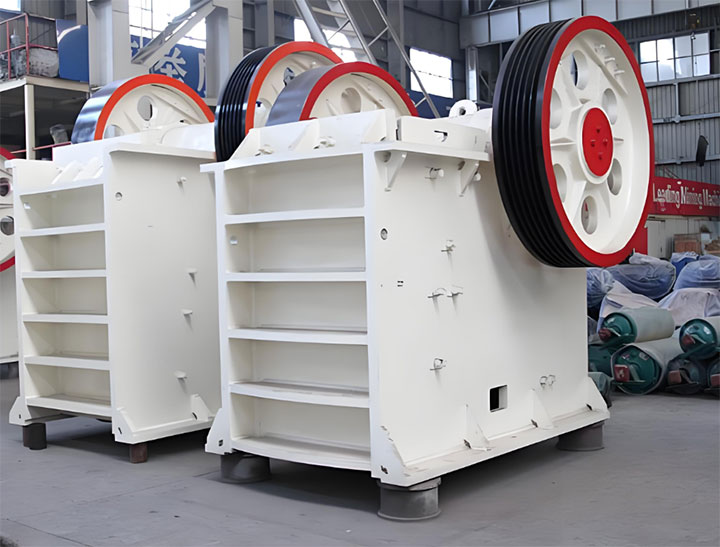

Jaw Crusher Working Principle

The jaw crusher operates based on "compression crushing." The equipment primarily consists of a movable jaw and a fixed jaw. After material is fed into the crushing chamber, the movable jaw, driven by an eccentric shaft, periodically moves toward and away from the fixed jaw. As the movable jaw approaches the fixed jaw, the material is crushed by compression, bending, and splitting. As the movable jaw leaves the fixed jaw, the crushed material is discharged from the discharge port under the action of gravity. This cycle repeats continuously, achieving continuous crushing.

This operating method makes the jaw crusher particularly suitable for coarse and medium crushing of hard materials. Its high crushing ratio, strong adaptability, and low energy consumption make it an ideal choice for primary crushing.

What are the advantages of the Jaw Crusher?

The Jaw Crusher is widely used in the mining, building materials, and other industries. Its main advantages include: it can crush a wide range of materials, from high-hardness granite to medium- and low-hardness limestone, offering a wide range of applications. Its mature design is easy to operate and maintain, with convenient parts replacement and a simple structure. It can adjust a wide range of particle sizes to meet various process requirements and has a high crushing ratio. It can cover a wide range of outputs, from small laboratory equipment to ultra-large mining crushers. Its flywheel and eccentric shaft are designed to be highly impact-resistant and stable. Its durability and low maintenance frequency result in low overall operating costs and a high return on investment. It can be used in fixed production lines or combined with mobile crushing stations, offering a wide range of adaptability.

Jaw Crusher Structure

jaw crusher consists primarily of the following components:

Frame: Constructed as a single piece of cast or welded material, it serves as the basic load-bearing structure of the equipment.

Moving and fixed jaws: The primary crushing components. The jaw plates are made of high-manganese steel or a composite wear-resistant material to ensure wear resistance and strength.

Eccentric shaft and flywheel: Provide the power and inertia required for the movable jaw's movement.

Toggle plate: Provides power transmission and safety protection. When the equipment encounters an unbreakable object, the toggle plate breaks to protect the main unit.

Adjustment device: Adjusts the size of the discharge opening, thereby controlling the particle size of the discharged material.

Lubrication system: Ensures lubrication of bearings and moving parts, extending their service life.

What are the applications of a jaw crusher?

Jaw Crusher is widely used in many fields due to its reliable structure and strong adaptability: in the production of sand and gravel aggregates, it is used for the preparation of aggregates for infrastructure such as highways, high-speed railways, and airport runways; in mining, it is used as coarse crushing equipment to process minerals such as iron ore, copper ore, and gold ore; in the cement industry, it is used for the primary crushing of raw materials such as limestone and clay; in the metallurgical industry, it is used to crush metallurgical waste slag to increase resource reuse rate; in the recycling of construction waste, it is used in conjunction with mobile crushing stations to recycle waste concrete, bricks, etc.; in addition, it is also used for the pre-crushing treatment of specific raw materials in the chemical industry.