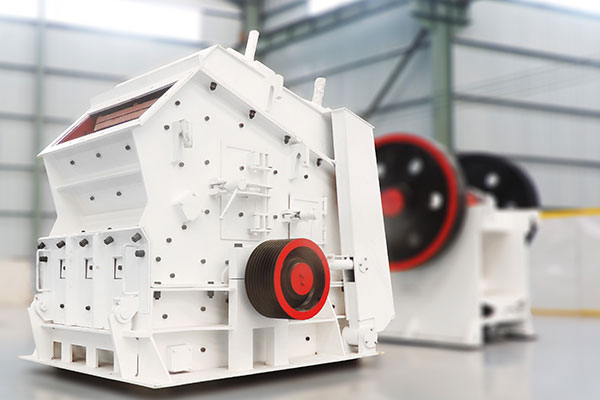

Gypsum hammer crusher

Gypsum hammer crushers typically have motor speeds between 750 and 1,500 rpm, and prices range from$1,000 to $60,000. Processing capacity: 5-50 tons/hour (depending on model) Input size: ≤300mm Output size: ≤30mm (adjustable) Motor power: 11-75kW Machine weight: 1.2-8 tons

What is gypsum hammer crusher?

Gypsum hammer crusher breaks down gypsum material from larger lumps into smaller, usable particles. This crushing increases the surface area of the gypsum, facilitating subsequent processing and utilization.

Gypsum hammer crushers have processing capacities ranging from a few tons to tens of tons per hour, depending on the model, adapting to different gypsum processing scales. Their high crushing ratio allows them to crush gypsum raw materials to the desired particle size, typically reaching a ratio of 20-50. Motor speeds typically range from 750-1500 rpm, ensuring efficient crushing. These devices are available in single-rotor and dual-rotor configurations to suit different gypsum production scenarios. Small gypsum hammer crushers cost approximately $1,000-$3,000, medium-sized ones range from $3,000-$10,000, and large or high-performance models range from around $10,000 to $45,000.

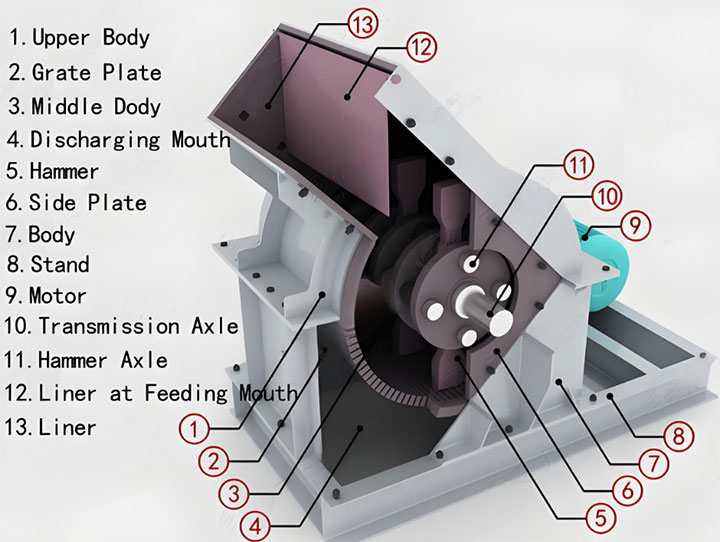

Gypsum hammer crusher diagram

What are the advantages of using a gypsum hammer crusher?

The following describes the advantages of the Gypsum Hammer Crusher from four perspectives: compatibility with gypsum material properties, production efficiency, operation and maintenance, and environmental friendliness.

Adaptable to gypsum characteristics, excellent crushing performance: Gypsum has a low hardness and is easy to process. The Gypsum Hammer Crusher crushes gypsum using the high-speed rotating hammers, eliminating the need for excessive impact force. Its high crushing ratio allows it to directly crush lumpy gypsum to the particle size required for subsequent processing (such as pre-processing gypsum powder). The resulting product has a uniform particle size and reduces secondary processing.

High processing efficiency and adaptability: Processing capacity ranges from a few tons to tens of tons per hour, accommodating operations of all sizes, from small workshops to large gypsum processing plants. With motor speeds ranging from 750-1500 rpm and single and dual rotor configurations, it can handle various types of gypsum, including natural gypsum and desulfurized gypsum. For slightly damp desulfurized gypsum, some Gypsum Hammer Crusher models feature an anti-clogging design to prevent caking that affects efficiency.

Easy operation and maintenance, low cost: The simple and compact structure makes installation and commissioning easy. Wearable parts such as hammers and liners are made of wear-resistant materials such as high-manganese steel, ensuring a long life and easy replacement, reducing downtime and maintenance. Intelligent control systems (such as one-touch start and stop and feed adjustment) reduce manual labor and labor costs.

Environmentally friendly, safeguarding the production environment: Most gypsum hammer crusher models are equipped with dust removal devices to effectively collect crushing dust, reducing emissions and protecting personnel health. Specialized models for desulfurized gypsum have anti-corrosion designs to prevent acidic gypsum from corroding the equipment and minimize pollutant leakage, meeting production requirements.

Gypsum hammer crusher technical parameters

| model | rotor diameter×length (mm) | Feeding port (length x width) (mm) | Optimal feed size(mm) | Processing power(t/h) | Motor power (kw) | Dimensions Length x Width x Height (mm) |

| PCZ1308 | Φ1330×790 | 870×780 | ≤380 | 60-160 | 132 | 2880×2130×2390 |

| PCZ1410 | Φ1400×1000 | 1060×740 | ≤450 | 80-210 | 2×90(160) | 2830×2100×2485 |

| PCZ1610 | Φ1600×1000 | 1090×930 | ≤480 | 100-230 | 2×132 | 3370×2415×2750 |

| PCZ1612 | Φ1600×1200 | 1340×1140 | ≤500 | 120-350 | 2×160 | 3370×2613×2750 |

| PCZ1615 | Φ1600×1500 | 1570×1140 | ≤550 | 200-550 | 2×200 | 3370×2925×2750 |

| PCZ1716 | Φ1700×1600 | 1420×1200 | ≤600 | 400-850 | 2×250 | 3520×3000×3210 |

| PCZ1720 | Φ1700×2000 | 2030×1200 | ≤650 | 500-1000 | 2×400 | 3670×3390×3330 |

| PCZ1920 | Φ1900×2000 | 1980×1210 | ≤750 | 800-1500 | 2×500 | 4490×3910×3600 |

| PCZ2225 | Φ2200×2500 | 2530×1610 | ≤1000 | 1500-3000 | 1250 | 4890×5010×4560 |

Gypsum hammer crusher equipment types

Gypsum hammer crusher types vary. Based on their structural design and rotor layout, they can be divided into single-rotor hammer crushers and twin-rotor hammer crushers. Single-rotor hammer crushers have a simpler structure.

The single-rotor gypsum hammer crusher features a single horizontal rotor equipped with multiple fixed or swinging hammers. It also comes with a feed hopper, crushing chamber, and discharge screen. The operating principle is that upon entering the crushing chamber, gypsum is impacted and crushed by the high-speed rotating hammers. It then collides with the chamber lining (impact plates) for further crushing, and particles that meet the required particle size are discharged through the discharge screen. This device offers a simple structure, low manufacturing and maintenance costs, and stable operation. It is suitable for gypsum with low hardness and small to medium feed sizes (≤500mm) and is commonly used in small and medium-sized gypsum processing plants (such as building gypsum and desulfurized gypsum production lines).

The twin-rotor gypsum hammer crusher features two counter-rotating parallel rotors, each equipped with independent hammers. The crushing chamber is divided into coarse and fine crushing stages. During operation, gypsum is first crushed in the first rotor, without intermediate conveying, and then directly enters the second rotor for fine crushing, resulting in a higher overall crushing ratio. Its advantages include a high crushing ratio, fine and uniform output particle size (adjustable to ≤5mm), and the ability to prevent material clogging (especially critical for slightly damp gypsum). It is suitable for large-scale gypsum processing (such as industrial by-product gypsum recycling and high-purity gypsum powder production) and for applications requiring high fineness of the finished product.

What is the price of a gypsum hammer crusher?

The price of a gypsum hammer crusher varies depending on factors such as the model, specifications, production capacity, quality, brand, and supplier. Smaller models range from approximately $1,000 to $3,000. For example, a PC400x300 model small hammer crusher costs approximately $1,960. Medium-sized models typically cost around $3,000 to $10,000. A PC600x400 hammer crusher, for example, costs around $4,400 to $4,500. A PC800x600 small slag hammer crusher for industrial gypsum is priced between $3,299 and $3,999. Larger or higher-performance models can cost over $10,000, or even more. Some large double-chamber hammer crushers or those with specialized features and high production capacity cost between $15,000 and $45,000.

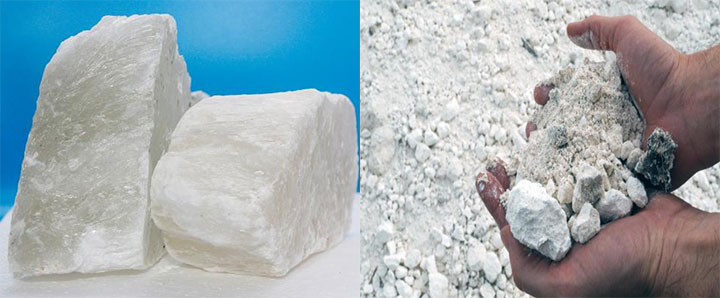

What is gypsum?

Gypsum is a common sulfate mineral characterized by low hardness, low density, strong chemical stability, and reversible hydration and dehydration properties. Gypsum is used in construction, such as making gypsum board and gypsum mortar. In the medical field, it can be used in medical plasters for fracture fixation and in ceramic molds.

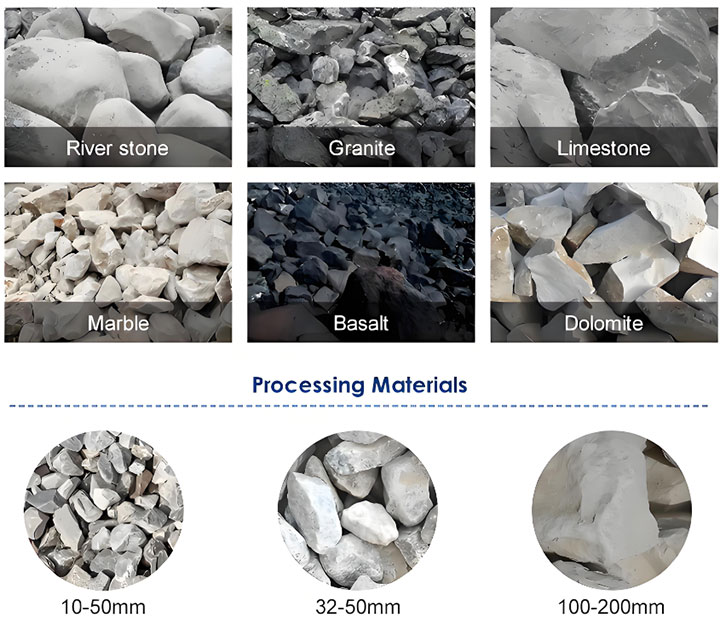

What materials are suitable for gypsum hammer crushers?

The Gypsum Hammer Crusher offers advantages such as high crushing efficiency, uniform finished particle size, strong adaptability to the low hardness of gypsum, and the ability to process both lump and granular gypsum raw materials (including wet materials, with some models featuring anti-clogging features). It serves as a core crushing device throughout the entire gypsum processing industry chain, from natural gypsum mining to industrial by-product gypsum recovery and final gypsum product production. It is widely used in the mining, building materials, metallurgy, and chemical industries.

The Gypsum Hammer Crusher can crush natural gypsum, whether it is fibrous gypsum, alabaster, or ordinary lump natural gypsum ore. It is particularly suitable for processing raw natural gypsum with a feed size of ≤500mm to meet subsequent processing requirements. For industrial by-product gypsum, such as desulfurization gypsum from power plants, phosphogypsum from phosphate fertilizer plants, and citric acid gypsum, the Gypsum Hammer Crusher's anti-clogging and anti-corrosion features prevent agglomeration and corrosion, ensuring stable crushing. In addition, for gypsum semi-finished products that need to be further processed into gypsum powder and gypsum board raw materials, they can also be refined to a particle size that meets the process requirements by adjusting the crushing ratio.