Z Type Conveyor

The price of Z Type Conveyor varies depending on its type, processing volume requirements, and whether it is customized. It usually ranges from US$160 to US$4,800.

Bucket volume: 1.8L or 4L

Vibrator hopper size: 550L * 550W

Frequency: 0.75 KW

Conveying height: 1800-4500 mm

Voltage: 220V/380V

Power (horsepower): 0.75 ~ 2.2KW

What is Z Type Conveyor ?

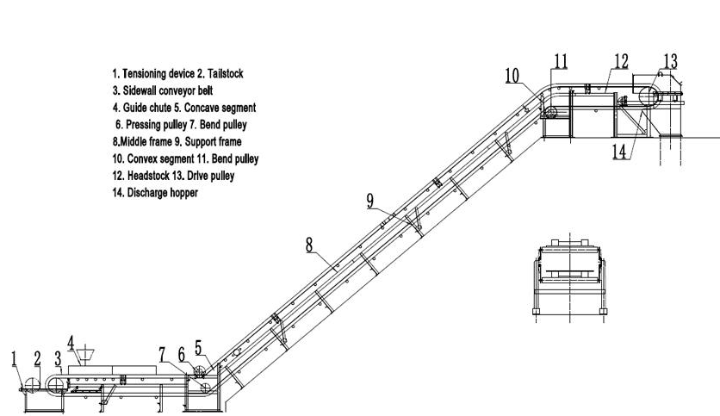

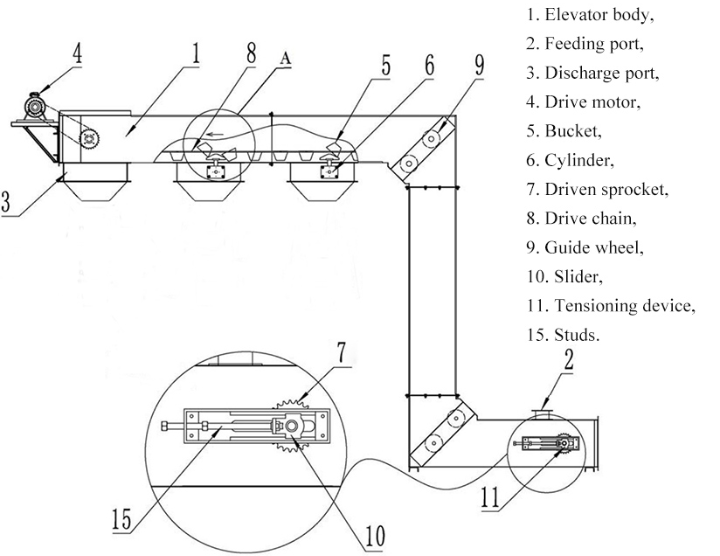

The main function of Z Type Conveyor is to realize horizontal conveying and inclined lifting of materials. This equipment usually presents a "Z" shaped layout, which can stably transfer materials from a lower plane to a higher plane while moving horizontally. Common types of Z Type Conveyors include Z-belt conveyors, which use conveyor belts with patterns, skirts or ribs to carry materials; and Z-chain bucket conveyors, which use a series of buckets fixed on the chain to complete the lifting of materials. Depending on the specific design and material characteristics, the processing capacity of Z Type Conveyor usually ranges from several cubic meters to hundreds of cubic meters per hour, and the lifting height can reach 1 meter to 30 meters.

What are the types of Z Type Conveyors?

With its unique "Z" shaped layout, Z Type Conveyor can simultaneously complete the tasks of horizontal conveying and inclined lifting. According to the different load-bearing and traction components, this type of equipment can be mainly divided into several types:

Z-type bucket elevatorThe capacity of a Z-type bucket elevator depends on the capacity of the bucket, the bucket distance and the operating speed. The capacity of small equipment can start from a few cubic meters per hour (about 0.5-2 tons), and medium and large equipment can reach tens of cubic meters per hour to hundreds of cubic meters per hour (about 5-100 tons), or even higher. This type of equipment has significant vertical conveying capabilities, and the lifting height of conventional models can usually reach 5 meters to 30 meters, and some customized equipment can even reach 60 meters or more. Although its main function is vertical lifting, the Z-type bucket elevator has horizontal conveying sections at both the feed and discharge ends, and the distance between these horizontal sections usually ranges from 1 meter to 10 meters.

The Z-type belt conveyor uses a special conveyor belt with corrugated flanges or baffles. It is designed to transport materials at a large angle, forming a "Z" shaped path. The Z-type belt conveyor can achieve a large vertical lifting height, usually from a few meters to 20 meters, and even higher heights can be achieved by connecting multiple sections. The inclination angle is usually greater than 30 degrees, and some designs can be close to 90 degrees. The handling capacity of the Z-belt conveyor depends on the belt width, belt speed and the height of the sidewall/guard. Small equipment can achieve a conveying capacity of tens of kilograms to several tons per hour (such as 10 kilograms to 6 tons/hour), while large industrial applications can reach hundreds of cubic meters per hour (for example, 28-800 cubic meters/hour).

Basic parameters of Z Type Conveyor

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

| Belt Width B (mm) | 400 | 500 | 650 | 800 | 1000 | 1200 | 1400 | |||||||||

| High guard H (mm) | 60 | 80 | 80 | 120 | 120 | 160 | 160 | 200 | 160 | 240 | 200 | 300 | 240 | 400 | ||

| minimum horizontal baffle spacing | 100 | 120 | 120 | 160 | 160 | 200 | 200 | 250 | 200 | 280 | 250 | 350 | 280 | 400 | ||

| Throughput | 30° | 28 | 36 | 50 | 71 | 104 | 120 | 157 | 195 | 216 | 327 | 331 | 466 | 500 | 794 | |

| (raw coal,idling 1m/s) | 45° | 19 | 25 | 33 | 57 | 83 | 97 | 127 | 157 | 175 | 271 | 267 | 384 | 414 | 680 | |

| M³/h | 60° | 15 | 19 | 23 | 40 | 58 | 69 | 90 | 112 | 124 | 197 | 190 | 278 | 302 | 524 | |

| 90° | 9 | 11 | 15 | 21 | 31 | 37 | 48 | 60 | 66 | 106 | 102 | 149 | 162 | 281 | ||

| Overall dimensions | High head belting leather surface H1 | |||||||||||||||

| 1200 | 1350 | 1615 | 1815 | 2000、2200 | 2300、2525 | 2525、2700 | ||||||||||

| High end belting leather surface H2 | ||||||||||||||||

| 690 | 800 | 950 | 1115 | 1250、1400 | 1600、1700 | 1600、1700 | ||||||||||

| High middle section of belt surface H3 | ||||||||||||||||

| 700 | 800 | 850 | 1115 | 850、1200 | 1400、1500 | 1600、1700 | ||||||||||

| middle period of anchor wide B1 | ||||||||||||||||

| 580 | 850 | 1020 | 1220 | 1440 | 1690 | 1890 | ||||||||||

What are the advantages of Z Type Conveyor?

Z Type Conveyor has good three-dimensional space utilization ability and can complete horizontal conveying and inclined lifting on the same equipment, thereby effectively saving floor space and avoiding the space waste caused by multiple independent conveyors, which is especially important for factories with limited space. In terms of material transportation, Z Type Conveyor shows the characteristics of stability and continuity. Compared with traditional bucket elevators, it has less impact and vibration during the lifting process, which helps to reduce the damage of fragile materials and ensure the stability and uniformity of material flow, which is conducive to the smooth operation of downstream equipment. In addition, Z Type Conveyor has a wide range of material adaptability and can adapt to various forms of materials such as granular, powdery, blocky, and bulky by replacing different bearing surfaces (such as patterned belts, skirt edge belts, hoppers, scrapers, mesh belts, etc.). In the inclined climbing section, Z Type Conveyor can effectively prevent material spillage and backflow, thanks to its specially designed conveyor belts or hoppers and other bearing components to ensure the effective transportation of materials.

What are the application scenarios of Z Type Conveyor?

As a versatile material lifting device, the Z Type Conveyor, with its unique structural design and outstanding performance, plays an indispensable role in industrial production. It cleverly combines horizontal conveying and vertical lifting functions, effectively solving material handling challenges in a variety of complex working conditions, including those at varying heights, in confined spaces, and for continuous conveying. The following are key applications for the Z Type Conveyor:

Spanning height differences: When a production line or process needs to transfer materials between equipment at different heights, Z Type Conveyor provides an integrated solution without the need for multiple independent devices. For example, lifting materials from a ground silo to a mixer or packaging machine at a high altitude.

Lifting tasks with limited space: When the workshop space is limited and it is impossible to install a long-distance inclined belt conveyor or multiple vertical elevators, Z Type Conveyor can complete the vertical material transportation task with a compact "Z" shape layout.

Continuous transfer of materials: When it is necessary to continuously and uninterruptedly transport bulk materials from low to high, such as granules, powders or small pieces of materials, Z Type Conveyor can provide a stable material flow to ensure the continuity of the production or processing process.

Smooth material transition: For some fragile materials or materials that do not want to be subjected to excessive impact during the conveying process, Z Type Conveyor can provide a smoother conveying process and reduce material damage compared to some lifting equipment.

What are the structures of Z type conveyors?

Z type conveyors can realize horizontal-vertical-horizontal continuous conveying of materials. This unique structure makes it perform well in situations where the material height needs to be lifted while taking into account horizontal conveying.

The main structural components of Z-type conveyors usually include the following parts:

Horizontal input mechanism: This is the starting part where the material enters the conveyor, usually a horizontal conveying section, used to receive and initially convey the material. It can be a belt conveyor, a chain conveyor or the bottom feed port of a bucket elevator, etc.

Vertical lifting mechanism: This is the core part of the Z-type conveyor, responsible for lifting the material from a low place to a high place.

Horizontal output mechanism: After the material is lifted vertically, it will enter this horizontal section, which is used to transport the material to a designated location or the next process link. Similar to the input mechanism, it can also be a belt conveyor, a chain conveyor, etc.

Drive device: It is usually composed of a motor, a reducer, a coupling, etc., to provide power for the entire conveying system. The location and form of the drive device will vary depending on the specific type and design of the conveyor, for example, it may be installed at the top or bottom of the vertical section.

Frame and support structure: Provides the skeleton and support of the entire conveyor to ensure stable operation of the equipment. Usually made of steel or other strong materials.

Conveyor belt/chain/hopper: This is the part that directly contacts and carries the material. Its material, form and size will be selected according to the characteristics of the conveyed material (such as abrasiveness, viscosity, temperature, etc.) and the conveying volume.

Tensioning device: Used to adjust the tightness of the conveyor belt or chain to ensure its normal operation and prevent deviation or slipping.

Redirection roller/guide wheel: Used to change the running direction of the conveyor belt or chain to form a "Z" shaped path.

Case of Z type conveyor

Due to its unique structural advantages, Z type conveyor is widely used in various industrial scenarios where materials need to be lifted from low to high and transported horizontally. It is often used in food processing, chemical production, building materials, warehousing and logistics. For example, in the food processing industry, it is used to lift bulk foods such as grains, potato chips, biscuits, and candies from the bottom of the production line to the packaging machine or the next process to ensure the continuous flow of materials and avoid cross contamination. Its closed structure and optional stainless steel material. Z type conveyors also play a key role in the chemical, plastic, mining, building materials and other industries. For example, it can be used to transport fertilizer particles, plastic particles, sand, cement, ore, etc., and lift them from storage silos to mixing equipment, packaging lines or screening equipment. For occasions where abrasive or corrosive materials need to be handled, Z type conveyors can be adapted by selecting special wear-resistant and corrosion-resistant materials to extend the service life of the equipment. Whether it is lifting bulk materials such as grains, snacks, powders, etc. from the bottom of the packaging machine to the weighing and filling equipment, or conveying construction waste and plastic particles from the ground to the crusher or silo, the Z type conveyor can stably complete the task. Its integrated horizontal-vertical-horizontal conveying capacity effectively reduces the floor space and transfer links required by the traditional multi-stage conveying system, thereby improving overall production efficiency.

Z Type Conveyor Manufacturers

Many Z Type Conveyor manufacturers offer customization capabilities to meet the specific needs of various industries. This customization typically involves structural and dimensional adjustments, belt and material selection, functional accessories, and control systems. Manufacturers can adjust the height, length, and width of the Z Type Conveyor to suit the customer's site space and production layout. This includes varying the ratio of vertical and horizontal sections to accommodate limited workshop space or connect production equipment at different heights. Furthermore, the location and size of the Z Type Conveyor's inlet and outlet can be customized to ensure precise integration with upstream and downstream equipment. Manufacturers offer a variety of conveyor belt materials to meet the characteristics of different materials. For example, for foods requiring hygienic conditions, food-grade stainless steel or plastic conveyor belts are used. For applications handling highly abrasive or high-temperature materials, wear-resistant and heat-resistant conveyor belts or metal chains can be selected. The shape and spacing of the baffles or hoppers on the conveyor belt can also be adjusted to suit the material form (e.g., granular, powdered, or bulk). To meet more complex functional requirements, manufacturers offer a variety of optional accessories and control systems. For example, cleaning devices, dust covers, weighing modules, or metal detectors can be added upon request. Customizable control options include variable frequency drive, automated control systems, and remote monitoring capabilities, enabling the device to be better integrated into existing automated production lines and achieve precise control and operation. These customization capabilities enable Z Type Conveyor manufacturers to provide customers with more targeted solutions, ensuring the device can reliably serve specific production conditions.

Z Type Conveyor can complete the horizontal movement and vertical lifting of materials on one machine at the same time, simplifying the complex conveying path. Its structure is usually compact, which helps to lay out in limited factory space. During the operation of Z Type Conveyor, the transfer of materials is relatively smooth, avoiding severe impact and shaking. In addition, by selecting different types of load-bearing components, such as belts with sidewalls or chain buckets, Z Type Conveyor can adapt to various forms of bulk materials and effectively prevent materials from spilling during inclined conveying. These characteristics make Z Type Conveyor an effective tool to ensure the continuity and stability of material flow in current material handling systems.